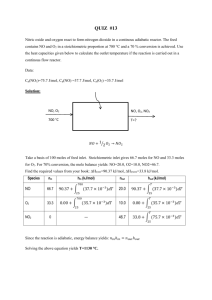

Exam 1 (FL2004)

advertisement

Fall 2004 ChE 471 Exam 1 (Closed book, closed notes) 1.The observed catalytic decomposition of ozone in the presence of nitrogen pentoxide exhibits the following rate form: RO3 k(O3 ) 2 / 3 (N 2O5 ) 2 / 3 The overall stoichiometry is: 2O 5 20 3 N 3O2 The following two mechanisms are proposed: Mechanism A: N 2O5 k1 NO NO3 ;K1 k1 /k1 2 k 1 k2 NO2 O3 NO3 O2 k3 NO3 O3 2O2 NO2 Mechanism B: k1 N 2O5 NO NO3 ;K1 k1 /k1 2 k1 k2 NO2 O3 NO3 O2 k4 NO3 NO2 O3 2NO2 The first step, common to both mechanisms, can be considered to be in equilibrium compared to other steps. Each elementary step rate constant has an activation energy associated with it, i.e., ki k ioeE i / RT . The equilibrium constant for the first step is the following function of temperature, K1 K1oeH r 1 / RT . a) Which mechanism is consistent with the observed rate form? Please, fully document your answer. b) If we represent theobserved rate constant, k, in terms of the usual Arrhenius form, i.e., k koeE / RT , show what is ko in terms of k20,k30,k40,K1o and what is the apparent activation energy E in terms of E1, E2, E3, E4 ,Hr1. 2. For a liquid phase reaction A products you have measured reactant concentration as a function of time in an isothermal, batch reactor and the data are given below: t(min) mol 0 5 10 20 40 60 100 CA 10 7.31 6.30 4.81 3.42 2.73 2.00 0 lit mol A at CAo = 10 min (mol/lit) and to achieve conversion of 80%. What should the volume of the plug flow reactor be? The PFR operates at the same temperature for which batch data are given. [Hint: Consider the relation between reaction time in the batch and space time in PFR]. You want to design a plug flow reactor to process the feed rate of 100 3. Gas-phase reaction A 4P was studied in a batch autoclave at constant volume and at constant temperature of 200˚C. The information obtained for the rate of disappearance of reactant A is presented in a tabular form below: PA (atm) 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 kmolA 0 0.08 0.25 0.32 0.41 0.48 0.52 0.55 0.6 0.6 0.6 RA 3 m min You are to operate continually a jet-stirred reactor for this reaction, which you can assume behaves as a continuous flow stirred tank reactor CSTR. The feed consists of 50% (molar) A and 50% inerts and is at a total pressure of 10 atm and 200˚C. We want to achieve 90% conversion of A. Find the reactor volume necessary for a production rate of 4 kmol P/min. The reactor operates isothermally at 200˚C . 4. A substrate inhibited enzyme catalyzed reaction, A P , exhibits a peculiar rate form and –1! RA 0.05 CA /(0.1 CA ) 2 (mol /L min) as its apparent order can vary between 1 We want to make FP = 100 (mol/min) of P at 99% conversion of A of the feed that contains C = 1 (mol/L). Ao You want to minimize the reactor volume needed to achieve the above production rate at the above specified conversion. To gain insight plot the rate (or its reciprocal) as a function of conversion in the conversion range from 0 to 0.99. a) What reactor type or reactor combinations do you recommend and why? b) What is the needed total reactor(s) size? Hint: This is a constant density system so CA = CAo (1-xA) and production rate FP = FAoxAf by stoichiometry and xAf = 0.99. FAo=Q CAo where Q (L/min) is the volumetric flow rate through the system.