Part-II

advertisement

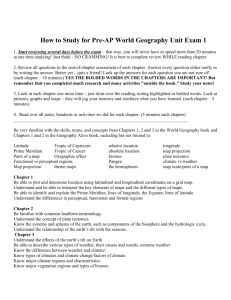

PRE-COURSE STUDY MATERIAL SD(P) AND CHEAP COURSES PART-II INS VALSURA JAMNAGAR 1 CONTENTS S. NO. TOPIC PAGE NO PURPOSE & SCOPE 3 Chapter 01 TECH ADMIN 4 Chapter 02 ELECTRICAL MACHINES 16 Chapter 03 POWER ELECTRONICS 32 Chapter 04 CONTROL ENGINEERING 46 INSTRUMENTATION AND TEST EQUIPMENT 64 Part-I Part-II Chapter 05 2 CHAPTER-5 INSTRUMENTATION AND TEST EQUIPMENT 1.1 Introduction 1.1.1 Maintenance and repair of various electrical equipment involves use of test equipment. Proper use of these test equipment reduces time of repair/maintenance, resulting reduced system down time. Knowledge of using test equipment is enhanced by regular use of these test equipment. Mastering on electrical equipment can only be achieved by mastering on the required test equipment. 1.1.2 Electronic measurements involve the fundamental electrical quantities of voltage and current and the inherent characteristics of resistance, capacitance, and inductance. In circuits being tested, voltage and current are dependent upon resistance, capacitance, and inductance for their distribution; therefore, voltage and current measurements are valuable aids in determining circuit component conditions and in the evaluation of symptoms. Practically any reading obtained from the use of test equipment will depend on these basic measured quantities of resistance, capacitance, and inductance. 1.2 Various Instruments and Test Equipment 1.2.1 Digital Multimeter The Digital Multimeter (DMM) displays measurement of DC and AC voltages as discrete numerals instead of a pointer deflection on a continuous scale. It is also used for measuring the continuity of wire or a circuit. Numerical readout is advantageous in many applications because it reduces human reading and interpolation errors, eliminates parallax error, increases reading speed and provides output in digital form which is suitable for further processing or recording. 3 Fig 6.2.1Digital Multimeter 1.2.1.1 Operation of Digital Multi Meter (a) Voltage Measurement. Select the appropriate function DC or AC and the voltage button, V. Now select the required range on the rotary range switch. Apply the input to the sockets labelled (+) and (-). It is advisable, where possible, to connect the low input to the lowest impedance with respect to ground. This will reduce common mode voltages. To measure a voltage above 1 KV, the HV probe is availed. For RF voltage measurement use the probe with the BNC to 4mm adaptor. (b) Current Measurement. Select the appropriate function, DC or AC along with the current button. Now select the required range on the rotary range switch. Apply the input to the (+) and (-) sockets for ranges up to 2 Amp. For the 10 Amp range, connect the high input to the separate 10 Amps terminal. The maximum continuous overload is 2 Amp and the fuse, provides protection for sustained overloads in case of excess current. The 10 Amps range is not protected. (c) Resistance Measurement. Select the function button to ohms and the appropriate range with the rotary range switch. Connect the resistance to be measured between the (+) & (-) socket. The internal current sources for measurement, give a negative voltage at the (+) socket. The input is protected up to 250 V rms on all ranges. 1.2.2 Shock Pulse Tester T-2000 Shock pulse tester T-2000 combines the function of a Shock Pulse meter, a vibration meter, and a tachometer. The instrument is used to check the operating condition of rotating machines in order to detect mechanical faults and provides data for effective preventive maintenance. With the T2000, maintenance personnel can monitor 4 all significant aspects of mechanical machine condition during a single inspection, such as: (a) The mechanical condition of rolling bearings (bearing damage development). (b) General machine condition (the effect of structural looseness, misalignment and out-of-balance on machine vibration). Fig 6.2.2 Shock pulse tester 1.2.3 Electrical Motor Checker EMC-22 1.2.3.1 Introduction EMC-22 provides a fast and easy means to detect electrical faultsshort circuits, open circuits, damaged insulation etc, in motor and other three phase machines. EMC-22 is used on stationary motors. The motor has to be isolated from its power supply before testing. There is no need to disconnect the supply cable, provided the power is switched off. Readings can be taken at any point along the motor power supply. The basic test can be made on site without disconnecting the phase windings. 1.2.3.2 The Basic Test. On any three-phase machines, an electrical fault can be detected in the following manner:(a) Measuring insulation resistance to earth. (b) Measuring and comparing the resistance of different phases of stator winding. (c) Measuring and comparing the inductance of different phases of stator winding. 5 Fig 6.2.3.2 EMC-22 1.2.3.3 Resistance and inductance values of each phase are measured and compared with each other. They should be equal or any difference between the values should be within acceptable tolerance limits. Measurements should be made in the above sequence. The sequence can be interrupted as soon as fault is detected. 1.2.4 Tong Tester 1.2.4.1 Introduction This instrument is used to measure current. Two basic versions which are available are for D.C. and the other for A.C measurement. The advantage of this instrument over other current measuring devices such as an AVO is that there is no requirement to break a circuit, to introduce the meter in series for the measurement. It is however less accurate. It is ideal for measuring the current in damage control cables and current drawn by motors, large transformers, etc. Fig 6.2.4.1 Tong tester 1.2.4.2 Operating Procedure Clip ON ammeter around each cable in turn and measure current. Select the highest scale reading initially to prevent damage to needle 6 1.2.5 Neon Tester 1.2.5.1 Introduction Neon Tester (N.T) is small and handy test equipment which is used to check whether the circuit is alive or dead. It is used to measure an approximate AC and DC voltage between 110 V and 700 V. It is also used to check whether three phase supply is available in the supply cables. A picture of a neon tester is shown below. Fig 6.2.5.1 Neon tester 1.2.5.2 Description This instrument consists of two, rubber hand assemblies with PVC insulated brass probes. One hand assembly incorporates a NEON LAMP and a solenoid, which can be actuated by AC or DC supply (red scale for DC and yellow scale for AC). To check the voltage, the switch (ring push button which is housed within the PVC insulated probe) must be pressed. When measuring AC voltages the frequency should be 60 Hz. Other frequencies will give inaccurate reading on scale. 1.2.5.3 Use of Neon Lamp The neon lamp is used to indicate the voltage and polarity. If an AC voltage is measured the neon will burn over its full length. If it is used on DC it will burn at one end only. 1.2.6 Strobo Scope 1.2.6.1 Introduction Stroboscope is test equipment, which is used to measure r.p.m of the running machinery. The equipment has a flashing lamp whose frequency can be varied. When the flashing frequency of stroboscope is synchronised with running machinery’s r.p.m, the r.p.m is displayed on the seven-segment display available on the stroboscope. 7 Fig 6.2.6.1 Stroboscope 1.2.7 Megger 1.2.7.1 Introduction Wee Megger is a type of self contained high generator, used to find the high resistance and insulation of the equipment. When very high resistance is to be measured the current produced with batteries are too small to be measured. It is therefore necessary to use much higher voltage. Another reason for using high voltage is to check the breakdown of insulation of cable. 1.2.7.2 Operation (a) Connect the load across Megger connections and rotate the hand wheel i.e. +ve terminal to inner conductor and -ve terminal to ground. (b) The scale should not show zero. It should be in mega ohms. e.g. for good insulation it must read more than 100 m ohm. (c) Testing capacitor:- Connect the capacitor under test to Megger. Rotate the hand wheel. If capacitor is charging, needle will start showing increasing resistance which means capacitor is good. If meter is steady, the capacitor is bad (not getting charged). (d) Testing insulation:- Connect the load across Megger connections and rotate the hand wheel i.e. +ve terminal to inner conductor and -ve terminal to ground. The scale should not show zero. It should be in mega ohms. e.g. for good insulation it must read more than 100 m ohm. 8 Fig 6.2.7.1 Wee Megger 1.2.8 Spectrum Analyser 1.2.8.1 Introduction Spectrum analysis is defined as the study of energy distribution across the frequency spectrum of a given electrical signal. The study gives valuable information about bandwidth, effects of different types of modulation and spurious signal generation. The knowledge of the above quantities and phenomena are useful in the design and testing of radio frequency (RF) and pulse circuitry. Fig 6.2.7.1 Spectrum Analyser 1.2.8.2 Spectrum analysis is divided into two major categories on account of instrumentation limitations and capabilities. These are:(a) Audio frequency (AF) analysis (b) Radio frequency (RF) spectrum analysis RF spectrum analysis covers a frequency range of 10 MHz to 40 GHz, and hence is more important, because it includes majority of communication, navigation, radar, and 9 industrial instrumentation frequency bands. Spectrum analyzers are sophisticated instruments which are capable of portraying graphically, amplitude of the signal as a function of frequency. These instruments find wide applications for measurement of attenuation, FM deviation and frequency. 1.2.9 Digital Oscilloscope 1.2.9.1 Introduction The oscilloscope is probably the most versatile tool for the development of modern electronic circuits and systems. This device allows the amplitude of electrical signal, such as voltage, current, power etc. to be displayed primarily as a function of time. The oscilloscope depends on the movement of an electron beam, which is then made visible by allowing the beam to impinge on a phosphor surface, which produces a visible spot. A view of Digital Oscilloscope TDS 220 from Tektronix is shown below and is discussed subsequently. Fig 6.2.8.1 Digital Oscilloscope 1.2.9.2 Function of oscilloscope. The oscilloscope is used to find out the following:(a) The amplitude of the signal (Voltage AC/DC) (b) Frequency of the signal (c) Phase difference of two signals (d) Wave form analysis or pulse measurement of quantities such as :(i) Rise time of the pulse (ii) Fall time of the pulse (iii) Over rising of pulse (iv) Pulse width 10 1.2.10 Signal Generator 1.2.10.1 Introduction The signal generator is used to provide known test conditions for the performance evaluation of various electronic systems and for replacing missing signals in systems which are being analyzed for repairs. The standard signal generator is a source of sine wave voltage with an appreciable range of frequency and amplitude both of which are known to a high degree of accuracy. The instrument is provided with means of modulating the carrier frequency which is indicated by the dial setting. The modulation is indicated by a meter. Modulation may be sine wave, square wave and triangular wave. The output signal may be amplitude modulated (AM) or frequency modulated (FM). Usually amplitude modulation is employed. Fig 6.2.9.1Signal generator 1.2.11 Time and Frequency Counter 1.2.11.1 Introduction The time and frequency counter is used to measure the frequency generated from an oscillator/sine-wave generator. The signal whose frequency is to be measured is fed to the frequency counter. The counter measures the signal and displays on LCD display. 11 Fig 6.2.10.1 Time and Frequency Counter 1.2.10.2 Principle of Operation The signal whose frequency is to be measured is divided into a train of pulses with duration of one cycle for the signal. Thereafter, the number of pulses which are applied in a definite interval of time are counted by means of electronic counter. Since the pulse represents the cycle of unknown signal, the number appearing on the counter is a direct indication of the frequency of the unknown signal. 1.3 Questions 1.3.1 What do you understand by CRETE? Which all test equipment come under CRETE? 1.3.2 What all precautions must be taken when measuring the insulation of a motor? 1.3.3 Where will you find the bearing diameter before entering the value into shock pulse tester? 1.3.4 What is the basic principle behind Tong Tester? 1.3.5 What all precautions must be taken when using Megger? 1.3.6 What device sweeps a band of frequencies to determine frequencies and amplitudes of each frequency component? 1.3.7 Name two instruments used to analyze waveforms? 1.3.8 How do you measure the continuity of a wire or circuit and which test equipment will you use? 1.4 Suggested Reading VP 204:- Instrumentation and controls VP 191:- Common Test Equipment 12 CHAPTER-6 INERTIAL NAVIGATION SYSTEM GYROSCOPE: It is a well balanced rotor which is spinning at a very high speed and has three degrees of freedom and two properties. These three degree of freedom are as follows:1. 2. 3. It rotates about it own axis which also known as spin axis. It drift about its vertical axis. It tilts about the Horizontal axis. PROPERTIES: The gyro scope has its two main properties which are explained below. RIGIDITY IN SPACE :- It follows Newtons First law. Rigidity in space means a highly spinning body will continue to remain in its position. In other words, It tends to maintain the direction it was given initially in relation to space PRECESSION:- Precession means in a free gyroscope having three degree of freedom, when a force is applied on any axis, it will act on the axis 90 degree ahead of it. In simple term we can say that the effect of the external force applied to the gimbal rings of the gyroscope is ahead 90° in the direction of rotation of gyroscope TERMS RELATED TO GYRO SCOPE: POLE OF GYROSCOPE: It is that end of the main axis looking from which the rotation of gyroscope rotor is sensed as counter clock wise (Anti clock) POLE OF FORCE: It is that end of gyroscope axis looking from which the action of the force is sensed as counter clock wise. (Anti clock) RULE OF POLES: When a moment or torque of external force is acting on a gyroscope, the pole of the gyroscope moves towards the pole of force along shortest path. MERIDIAN: It is that vertical line which joins two poles north south and divided the earth in two equals parts from any side. 13 EFFECT OF EARTH’S ROTATION AT EQUATOR:- When the gyroscope is placed in the equator pointing in the east west direction it has got maximum rate of tilt that is 360 in 24 hours or 15 per hour. A free gyro at the equator after 12 hrs will appear as if direction of axis of gyroscope has changed but practically it does not happen; only the earth’s direction has changed. This is known as apparent effect of gyroscope. 14 EFFECT OF EARTH’s ROTATION AT POLE:- When the gyroscope is placed in the pole and axis is horizontal position it will have maximum drift that it will drift through 360 in 24 hrs or rate of drift is 15 per hour. GYROSCOPE SPIN AXIS At Equator (0 deg latitude) gyroscope has got maximum tilt and 0 deg drift. At poles (90 deg latitude), it has maximum drift and 0 deg tilt The earth rotation-900 knots.(1 knot=1852mtrs) Drift is increasing towards pole and tilt is increasing towards the equator. 15 EARTH AND GYRO ROTOR INHERENT PROPERTY Horizontal Earth rate causes TILT (RW cos L) Vertical Earth rate causes DRIFT (RW sin L) PATH TRACED BY NORTH END OF GYROSCOPE 16 PATH TRACED BY GYROSCOPE IN 24 HRS STARTING POINT ANGLE OF TILT=O ANGLE OF DRIFT=0 RATE OF TILT=0 RATE OF DRIFT= MAX RATE OF TILT = 0 AFTER 6 HOURS ANGLE OF DRIFT = MAX RATE OF DRIFT = 0 RATE OF TILT = MAX ANGLE OF TILT = ½ MAX CONVERSION FROM GYRO SCOPE TO GYRO COMPASS:-For this gyro scope should not drift and tilt so there is some factor are required to make gyroscope into gyro compass. We have to reduce one degree of freedom and gyro scope is made pendulous (bottom portion heavy). To make gyroscope to gyro compass some extra element is required; the group of these element is known as gyro sphere . 17 Gyro sphere is known as sensitive element Two rotors are placed at 45 deg from main meridian both side are variable w.r.t. Latitude. w.r.t. Earth’s rotation, by adding some extra weight to rotor or by resisting one degree of freedom- the center of gravity of rotor can be shifted from point of suspension of rotor. The distance between point of suspension to the center of gravity of rotor is known as META CENTRIC HEIGHT. PRINCIPLE OF PENDULOUS GYROCOMPASS: - From starting the gyro axis is horizontal to earth surface. In position I) The weight of rotor mg is not going to effect on tilt or drift. II) Centre of gravity changes from its vertical position at 0 deg. What is pendulous moment? Pendulous moment = mg a sinӨ It is the force which tries to come towards the line joining of the earth’s centre and position of gyro. At point (P1)rate of tilt (V1) becomes maximum. At point (P2)rate of tilt (V1) becomes minimum (West side)V1 the directional torque which acts towards the meridian v2 tilt rate angle of tilt is more so rate of precession is also more. Gyro compass takes 84.4 minutes (standard value) to complete one full revolution it makes or traces a elliptical path. In the gyro compass these two factors are working while it rotates w.r.t Earth’s V1-by which the pole of gyrocompass tries to 18 UNDAMPED OSCILLATION When the rotor is rotating the gyro compass is kept at any intermediate latitude, both the force will effect to poles of gyro compass, the resultant of both will trace a elliptical path. When the gyrocompass comes towards meridian it has got maximum tilt and when it goes away from meridian its tilt is decreasing thus torque is decreasing . The torque is directly proportional to tilt angle which try to bring the gyro poles towards the meridian. 19 DAMPED OSCILLATION With a narrow tube, oil damper is interconnected with gyro poles in gyro compass. The sensitive element is made pendulous. With effect of this damper gyro is going to direct one path that path of “spiral type”. When the gyro axis is in horizontal place and deviated maximum, oil level in one of the vessel is max”. By this three kind of precession is existing. Rate of main precession V1(pendulum moment) Rate of rise of gyro axis V2 Rate of additional precession (the cause of add. Precession is oil damper and rate of add. Precession always acts towards meridian. 20 MOVEMENT OF MAIN AXIS 21 IN POSITION 1_ Gyrocompass axis is horizontal and northern end is deviated eastward from meridian by an angle ‘L’ There is more oil in northern vessel-three forces are acting on gyrocompass axis. 1.Due to pendulum movement 2.Due to excess oil in N-vessel 3.Rate of tilt .Resultant of these forces meridian. presses the northern end towards In 1 case when gyrocompass axis is horizontal, centre of gravity is at the line of position and in earth’s center no tilt appears If there is no tilt no precession is caused but additional precession will appear due to oil damper, because oil is more in one vessel (N). At east of meridian gyrocompass Pole is going to tilt upward at the time period passed. IN POSITION 2 Some volume of oil flows into the southern vessel so moment due to oil control element is decreased As the pendulum momentum and moment due to oil control element are in same direction, northern end is precessed to meridian more faster than increase of undamped oscillation in Pendulum momentum due to center of gravity of gyro-sphere element pendulum. IN POSITION 3 As time period gyrocompass axis is aligned with the meridian, oil in both will be equal. So the moment due to oil control element will be zero. But it traverse the meridian plane because of pendulum moment. (Pendulum moment is max.) IN POSITION 4 The oil will be more in southern vessel, so because of this moment gyro axis will be precessed towards meridian. 22 In this case, moment due to pendulum and moment due to oil element are opposition to each other. Then gyro axis will move very slow from meridian the ase of un-damped oscillation due to slow movement from meridian, the westward deviation from meridian is less than eastward deviation i.e. oscillation of main axis about the meridian is damped IN POSITION V Gyro axis is aligned with horizontal plane excess of oil will be maximum in southern vessel, so additional precession due to oil element will be max. So speed of eastward precession will also be maximum on this point. IN POSITION VI The oil in southern part is decreased, even then, precession due to oil element is still eastward. In this case, precession due to pendulum moment and precession due to oil element are having same direction, so gyro compass axis precessed to meridian more faster than in case of un-damped oscillation. IN POSITION VII As the gyro compass with meridian, oil in both vessel are equal therefore precession moment due to oil damper is zero. Due to pendulum moment gyro axis traverse meridian plane. IN POSITION VIII Excess of oil will be in northern vessel. In this case, both the moment are opposite to each other so gyro-axis moves very slow from meridian. Now eastward deviation is lesser than western deviation i.e. oscillation is further damped This movement will continue till gyro-axis is settled and aligned the meridian. In equilibrium position gyro-axis is stabilized in meridian plane and northern end is tilted upward above horizontal plane by an angle. 23 This create pendulum moment of such value that angular velocity of precession caused by this moment is equal to angular rotation of meridian in space gyrocompass axis, after stabilized, will remain in meridian plane moving with same speed as speed of meridian plane. DAMPING FACTOR It is the ratio of amplitude of gyrocompass sensitive element axis departure to the amplitude of the following departure at the opposite side of meridian plane and it is constant and it is denoted by F F=a1/a2=a2/a3=an/an+1 F=2.5 to 6 24 SETTLING PERIOD:- Settling period of gyro compass is equal to” damping factor x time taken for one oscillation”. Time taken for one damped oscillation is 110 minutes from point P to Q, or Q to R in fig 2. Damped oscillation time is more than un-damped oscillation • Un-damped oscillation gyrocompass is moving with constant speed • Damped oscillation, when gyrocompass moves towards meridian V1 and V3 are acting in same direction and after meridian V1 and V3 acts in opposite direction so time period while moving towards meridian is less and time period while moving away from meridian is increasing. If time taken for one oscillation is 110 minutes and damping factor is 2.5 then • Settling period=2.5x110 = 275 minutes • => 4 hours 35 minutes 25 DISPLACEMENT TYPE ACCELEROMETER Measurement is based on the principle of Inertia Inertia is characterised by a force ‘F’ which under an acceleration ‘F’ moves a mass in the opposite direction Comprises of a Pendulum (P) suspended by a Flexible Blade (L) in order to minimise the strains involved Point of equilibrium of the pendulum is obtained by Permanent Magnet Any movement is measured by a Capacitive Pick Off (C) The return of Pendulum to the point of equilibrium is ensured by a Torque Motor winding of pendulum itself 26 Movements of pendulum are analysed by ‘Pick-Off’ system comprising of two capacitors C1 & C2 connected in a Wheatstone Bridge In the presence of Acceleration the value of C1 C2 and an error current is generated This current is used to calculate the acceleration and also returned to accelerometer torque motor for allowing the pendulum to return to initial position 27 STRAPDOWN PRINCIPLE Inertial navigation is a process which allows a vehicle to locate itself in space (position, speed and attitude) in permanent, automatic and autonomous manner. The sensors used are inertial detectors (gyros and accelerometers) and they are attached on a platform, which can be either stabilized (gimbaled systems), or linked to carrier vehicle (strap-down systems) Note: The SIGMA 40 INS is the strap-down type INERTIAL NAVIGATION SYSTEM An inertial navigation system is a navigation aid that uses a computer and motion sensors to continuously track the position, orientation, and velocity (direction and speed) of a vehicle without the need for external references. Other terms used to refer to inertial navigation systems or closely related devices include inertial guidance system, inertial reference platform etc. An inertial navigation system includes at least a computer and a platform or module containing accelerometers, gyroscopes, or other motion-sensing devices. The INS is initially provided with its position and velocity from another source (a human operator, a GPS satellite receiver, etc.), and thereafter computes its own updated position and velocity by integrating information received from the linear and angular accelerations applied to the motion sensors. The advantage of an INS is that it requires no external references in order to determine its position, orientation, or velocity once it has been initialized.Therefore, it is immune to jamming and deception ADVANTAGES OF STRAPDOWN SYSTEM Lightweight digital computers permit the system to eliminate the gimbals, creating "strapdown" systems, so called because their sensors are simply 28 strapped to the vehicle. This reduces the cost, eliminates gimbal lock, removes the need for some calibrations, and increases the reliability by eliminating some of the moving parts.. A strapdown system has a dynamic measurement range, several hundred times than a gimbaled system. That is, it must integrate the vehicle's attitude changes in pitch, roll and yaw, as well as gross movements. Gimballed systems could usually update at rate of 50 to 60 updates per second. However, strapdown systems normally update about 2000 times per second. The higher rate is needed to keep the maximum angular measurement within a practical range for real rate gyros: about 4 milliradians. STABILISED PLATEFORMS: Plate forms which are kept horizontal with respect to earth with the help of some feed back mechanism. 29 INERTIAL NAVIGATION SYSTEM SIGMA 40 MAIN FUNCTIONS Real time generation of the carrier’s attitude(roll, pitch) & heading Information Real time generation of the position and speed information hybridization of Navigation data from Log and GPS MAIN UNITS OF SIGMA 40 The system consists of the following units: -INU – INERTIAL NAVIGATION UNIT -CDU - Control and Display Unit -UPS 30 -DDU - Data Distribution Unit COMPONENTS OF SIGMA 40 INS INERTIAL NAVIGATION UNIT BSI – Inertial Sensor Block EB Module RS 422 Module Power Supply Module HT/ THT Module (4kV, 900 V and125 V) UTR-SP Module Synchro Module 31 SENSOR BLOCK (BSI) Three GLS32 Laser Gyros : Gives Rotation Speed and Rotation Angle Three Accelerometers : Gives Force Applied in the direction of Type A 600 Axis (Acceleration) EACC Board : Electronic Circuit needed to Servo Control the Accelerometer’s Pendulum The EEPROMs which contains the Sensors unit’s calibration data is installed in EACC. LASER RATE GYRO PRINCIPLE The Difference in path Length (∆L) is directional proportional to Angular Rotation (ω). 32 When course is steady:- Path traveled by F1=2πR Path traveled by F2=2πR When Course changes:- Path traveled by F1= 2πR + AB Path traveled by F2= 2πR - AB Difference in Path Length i.e. ∆L Now ∆L ∆L = 2AB = 2RӨ (Since AB=RӨ) = 2R ωT (As D=S x T) = 2Rω x 2πR (Where 2πR is Total Distance) = 4πR² ω (C=Speed of Light) C Now ∆L = K ω ( As Area of Circle 4πR² & Speed Of light C are Constants) Conclusion: “∆L α ω” Difference In path Length is directly proportional to Angular Rotation. HOW RLG WORKS ? 33 The laser generates a very coherent beam of light. This means all the photons are at one specific frequency. The beam is split into two beams that travel the same path but in opposite directions: one clockwise and the other counterclockwise. The beams are recombined and sent to the output detector. In the absence or rotation, the path lengths will be the same and the output will be the total constructive interfernence of the two beams. If the apparatus rotates, there will be a difference in the path lengths travelled by the two beams, resulting in a net phase difference and destructive interference. The net signal will vary in amplitude depending on the phase shift, therefore the resulting amplitude is a measurement of the phase shift, and consequently, the rotation rate. Doppler shift in sound frequency. An inbound train whistle changes from high to low pitch as the train goes by and then outbound relative to the observer who is standing still waiting to cross the tracks. Same theory applies to light 34 SAGNAC EFFECT: F+ & F- : Two similar Light Beams Traveling in Opposite Direction from ‘A’ If the apparatus is stationary the beams will meet each other at ‘A’. The path lengths of both beams will be same. This results constructive interference of two beams. If the apparatus rotates the beams will meet each other at ‘B’ and there will be a difference in the path lengths of two beams,. F+ travels an additional distance of ‘AB’ This results in net phase difference and destructive interference of two beams. The net signal will vary in amplitude depending on the phase shift, therefore the resulting amplitude is a measurement of the phase shift, and consequently, the rotation rate. 35 ADVANTAGES OF RLG The Ring Laser Gyros (RLG) can be used as the stable elements (for one degree of freedom each) in an inertial guidance system. There are no moving parts. Compared to the conventional spinning gyro, this means there is no friction, which in turn means there will be no inherent drift terms. Additionally, the entire unit is compact, lightweight and virtually indestructable, meaning it is compatible even in aircraft. A single RLG can measure any rotation about its sensitive axis. This implies that the orientation in inertial space will be known at all times. The elements that measure actual accelerations can therefore be resolved into the appropriate directions. Laser (RL) platforms are basically "ready-to-go" as soon as power is applied. 36 BRIEF ABOUT SAGNAC AND THE EFFECT The first ring interferometry experiment aimed at observing the correlation of angular velocity and phase-shift was performed by the Frenchman Georges Sagnac in 1913, which is why the effect is named for him. Its purpose was to detect "the effect of the relative motion of the ether". In 1926 a very ambitious ring interferometry experiment was set up by Albert Michelson and Henry Gale. The aim was to find out whether the rotation of the Earth has an effect on the propagation of light in the vicinity of the Earth. The Michelson-Gale experiment was a very large ring interferometer, (a perimeter of 1.9 kilometer), large enough to detect the angular velocity of the Earth. The outcome of the experiment was that the angular velocity of the Earth as measured by astronomy was confirmed to within measuring accuracy. The ring interferometer of the Michelson-Gale experiment was not calibrated by comparison with an outside reference (which was not possible, because the setup was fixed to the Earth). The Michelson-Gale experiment had no scientific impact, but it is technically very interesting. Astronomers measure the Earth's rotation by tracking stars, that is: measurement of rotation with respect to other celestial bodies. The novelty of the Michelson-Gale experiment was that it measured the rotation of the Earth with respect to space. The experiment did not involve reference to other celestial bodies: not for the measurement itself and not for calibration of the instrument. 37 LASER RATE GYRO : INTERFERENCE & BLIND ZONE At point of bright fringe F+ and F- waves arrive in phase (Constructive) At point of dark fringe F+ and F- waves arrive in phase opposition (Destructive) Blind Zone is the range of speed for which the gyro provides ‘Nil’ measurement To eliminate blind zone a mechanical vibration produced by an activation motor “Dither” is superimposed to the vibrations that are to be measured HT/THT MODULE Function : To provide the following voltages 4000 V : LASER Initiation 900 V : Sustained maintenance of LASER 150 V : Dither Mechanism 38 ELECTRONIC (EB) MODULE Acquisition of data from gyros and accelerometers Sensors unit’s control computations by TMS type Processor Analog and digital Control of sensor units Management of VME bus used for interchange of information with UTRSP module Management of I2 C serial bus with EACC board’s EEPROM Real time generation of data UTR-SP MODULE Processing Unit Module (UTR-SP) is the equipment’s Main Computer Based on Integer Processor and a Floating Point Coprocessor and it operates of SPARK Architecture functions All complex processing at medium frequencies like Navigation & Hybridisation computations , INU & CDU management Interchanges data with EB and RS 422 modules via motherboard’s VME bus and via three RS 422 links RS1 : UTR with CDU RS2 : UTR with Synchro Module RS3 : UTR with J2 for Test RS 422 MODULE Provides Four RS 422 Serial Links to outside (RS1 - RS4) RS 422 Module is managed by TMS type processor Maximum Speed : 76800 Bauds Optional RS 422 module can be plugged in (RS5- RS8) Connections of RS 422 Module RS1 : 16 Hz for Log Input RS2 : 100 Hz for Attitude Output RS3 : 1 Hz for GPS Input 39 RS4 : 10 Hz for Navigation Output SYNCHRO MODULE Function: Synchro Module performs following functions Digital to Synchro conversion of Attitude and Heading Data Interface UTR-SP Module via a RS 422 Link POWER SUPPLY MODULE Function:Power supply Module generates various power supplies as given below for components of Inertial Navigation Unit 5 V K 0.15 V , 30 W (6A) , Thermal tripping at 125 deg C and reset at – 40 deg C to + 105 deg C +15 V -15 V 0.15 V K 0.45 V, 15 W (1 A) , Thermal tripping at 125 deg C and reset at – 40 deg C to + 105 deg C DATA DISTRIBUTION UNIT:-The Data Distribution Unit ensures the distribution of Navigation information between INU ‘A’ & INU ‘X’ and Ship’s users Purpose: Interface with INU ‘A’ & INU ‘X’ Automatic or Manual selection of INU Power Amplification of Synchro Signals Direct Distribution of Signals from INU ‘A’ & INU ‘X’ Distribution of Navigation Information after their selection Functions The Data Distribution Unit ensures the interface between the Ship and INUs Log Signal to INU ‘A’ and INU ‘X’ via RS 422 line GPS Signal to INU ‘A’ and INU ‘X’ via RS 422 line 115 V 60 Hz Power supply to UPS ‘A’ & UPS ‘X’ 24 V DC from UPS ‘A’ & UPS ‘X’ to INU ‘A’ and INU ‘X’ Signals from UPS ‘A’ & UPS ‘X’ to Alarm Box ‘A’ & ‘X’ Distribution of INU’s Output Signals 40 41 COMPONENTS OF DDU The following are the various components fitted inside the DDU Six Synchro Amplifier A1,A2 : Heading (Fine & Coarse) A3,A4 : Roll ( Fine & Coarse) A5,A6 : Pitch ( Fine & Coarse) A row of 17 Relays : R0 to R16 A row of 04 Relays : R17 to R20 AC/DC (115 V 60 Hz / 5 V DC ) Converter for power supply to Synchro Amplifiers A Terminal Block for internal wiring 42 CONTROL & DISPLAY UNIT The Control and Display unit consists of the following • • A 4 line 20 character electro luminescent read out A green indicator light indicating Operating mode Lit : Navigation Blinking : Alignment Mode • An orange indicator light showing carrier’s station status Lit : Maintenance Mode Blinking : Quay Off • • : Sea A red light indicating the type of equipment failure A back lit key board with 4 rows of 9 keys , including 9 action keys and 27 double action keys 43 FUNCTIONS OF CDU The following are the main functions of CDU Conversion of data on a read out Conversion of commands originating from keyboard to data Coupling of data with the computer via RS 422 link Managegement of self test and configuration The CDU configuration is stored in the EEPROM UNINTERRUPTED POWER SUPPLY 44 The UPS is used to provide Sigma 40 INS with an uninterrupted 24 V DC Power supply Components: Two in number 12 V Nickel- Cadmium batteries (10 Ni-Cd Cells each) One in number DC/DC converter Battery and Power Level monitor Specifications : 115 V 60 Hz Input Power Supply 24 V DC output Power : 75 W Temperature : -10 deg C to + 55 deg C Batteries : 12 V 1.7 AH (30 Minutes) ANALYTICAL PLATFORM Analytical Platform is an imaginary platform, the ‘XY’ axis of which is maintained locally horizontal, with ‘X’ axis pointing north and the ‘Z’ axis is 45 maintained vertically. This is achieved by correcting the platform using mathematical calculations based on the values obtained from sensors Note: The navigation computations are realised in the stabilised analytic point of reference. FUNCTIONAL BLOCK DIAGRAM OF SIGMA 40 INS SEARCH FOR VERTICAL 46 When accelerometer measurement axis is not perpendicular to G the accelerometer will measure a fraction of G according to the offset angle The measurement will be taken on ‘X’ and ‘Y’ axis in order to know the value of offset in horizontal plane These values will be used to initialize the analytical platform in the horizontal plane GENERATION OF NAV DATA Sigma 40 generates speed, attitude and heading data from the information provided by the inertial sensors These data are generated from an Analytical platform forming an oriented trihedral on axes of which speed increments received from accelerometers are projected as well as from a trihedral whose change over angles are supplied by the rate gyros ( Mobile Platform) 47 ALIGNMENT The navigation mode is preceded by the alignment mode. Alignment is compulsorily made before Navigation phase. This mode is used to – Start up the equipment, --search horizontal, – Search North on the analytical platform. This mode runs in three phases and is automatically enabled after start up. > Initialisation and self-test : This phase consists in starting up the equipment, it lasts approximately 7 seconds. > Coarse alignment : During this phase the analytical platform is set horizontally, then the north is searched. Fine alignment : During this phase, the alignment is progressively refined, to achieve the highest possible performance features when switching to the navigation mode. There are two types of alignment Quay : Duration 15 Minutes : Alongside Sea : Duration 30 Minutes : At Sea 48