Development of a Bioreactor to Simulate

Drug Adsorption from the Small

Intestines into the Blood stream

BSE-4126 Comprehensive Design Project

Drafted May 4, 2009

Purpose: The purpose of this report, at its fundamental level, is to explain the problem and our

approach to its solution. This will be accomplished by clearly defining: the problem, the scope

of work, the necessary background information, the design and its alternatives, the work plan,

and safety measures. The criteria and constraints of the project will be described as well as

evaluated in this document.

Team Name:

Hungry Hippos Engineering

Group Members:

David Morgan

Kevin Richter

*Neil Templeton*

Advisors:

Dr. Mike Zhang

Dr. Robert Grisso

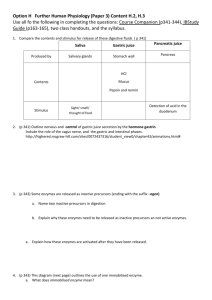

EXECUTIVE SUMMARY:

Development of a Bioreactor to Simulate Drug Adsorption from

the Small Intestines into the Blood stream

When a new drug is released on the market, in general, it is 10 to 15 years in the making. Occasionally,

it takes all of 10 years to learn that the drug being developed, does not meet regulation. This represents

a monumental risk that all pharmaceutical companies take on, and underscores high prescription drug

costs for Americans.

It was determined is estimated that 30-50% of the total developmental cost for a given drug is paid in

clinical trials. All Drug testing on humans represents a significant undertaking on the company’s part,

and a great deal of its budget is tied up in insurance. To quantify this in monetary value, 50 to 300

million US dollars are spent on clinical trials, for any given drug.

Drug kinetics modeling is not a new concept, and on a basic level this task has been performed by the

pharmaceutical industry for many years. What has not been performed is the advancement of this

modeling, especially in a non invasive in vitro environment. A two compartment model (standard of

industry) to explain drug adsorption with a central excreting and a peripheral compartment tells very

little about the bioavailability of a drug. Bioavailability is analogous to Gibbs free energy, except in this

case, the question is what portion of the drug is available to actually do work.

When a drug is taken orally into the body, a great deal of the drug is never adsorbed past the small

intestine’s folds. Of the drug that makes it to the blood stream, only a portion of the drug will ever

make it be transported to the intentional site. This explains the concept of bioavailability, which in a

sense is the fundamental concern of any type of drug introduced into the body. It tells you when the

drug will be available to produce the desired effect. The multi-stage bioreactor developed by Hungry

Hippos Engineering will give pharmaceutical companies this information at lower costs and in less time.

Hungry Hippos has addressed the pharmaceutical industry’s critical challenge in research and

development: cost. Enzyme inhibitor drugs make up nearly half (47%) of drugs currently marketed

today, making it the most common type of drug. Therefore, it seemed appropriate to develop a design

that could model this type of drug. This design can effectively explain the motion of oral drugs through

the stomach, small intestines, and into the blood stream. It can show the impact of food inhibiting the

absorption of the drug through the small intestines, as well as how the stomach’s pH can alter a drug

and its associated encapsulation. Not only can the design predict the mass balance of a given drug, but

the overall rates of reaction in various stages.

Modeling after a drug well studied and still widely used, Captopril, Hungry Hippos can reproduce the invivo performance of the drug in our specific reactor design. With this solution, predictions can be made

on many types of upcoming enzyme inhibiting drugs in the pharmaceutical industry. Tests can be

performed on our bioreactor design in a controlled environment, with no risk to human patients. This

will accomplish the overall goal of this project, an increase in patient safety. This design can decrease

the risk for allergic reaction or overdosing, because scientists will better understand drug absorption at

various stages as well as the reaction kinetics representative of the human body. This technology truly is

2

advantageous to pharmaceutical companies, as less clinical trials correspond with decreasing insurance

costs. Conversely, this gain can be returned to the consumer and prescription drug costs will decrease.

Details of design, cost and issues

3

PROBLEM STATEMENT .......................................................................................................................7

BACKGROUND SITUATION ..................................................................................................................7

CONNECTION TO CONTEMPORARY ISSUES .........................................................................................7

SCOPE OF WORK ................................................................................................................................8

JUSTIFICATION FOR RESEARCH ...................................................................................................................8

OBJECTIVES ..........................................................................................................................................8

DELIVERABLES .......................................................................................................................................9

DESIGN CRITERIA AND CONSTRAINTS .................................................................................................9

LITERATURE REVIEW ........................................................................................................................ 10

GENERAL INFORMATION ........................................................................................................................ 10

DRUG ADSORPTION .............................................................................................................................. 11

PHARMACOKINETICS ............................................................................................................................. 12

CAPTOPRIL KINETICS ............................................................................................................................. 14

ORAL DRUG INFORMATION .................................................................................................................... 16

CAPTOPRIL INFORMATION ...................................................................................................................... 17

STOMACH AND SMALL INTESTINES ANATOMY ............................................................................................. 18

GENERAL........................................................................................................................................................ 18

STOMACH ...................................................................................................................................................... 19

SMALL INTESTINE............................................................................................................................................. 20

MICROORGANISMS .......................................................................................................................................... 20

OTHER CONSIDERATIONS .................................................................................................................................. 21

SAFETY AND REGULATIONS ..................................................................................................................... 21

FEDERAL REGULATIONS .................................................................................................................................... 21

ANIMAL TESTING ............................................................................................................................................. 22

GLOBAL ENVIRONMENT ................................................................................................................... 22

SAFETY ASSESSMENT ....................................................................................................................... 22

ENVIRONMENTAL CONSIDERATIONS ................................................................................................ 23

4

ALTERNATE DESIGNS ........................................................................................................................ 24

STOMACH/ENZYMATIC SI MODELS .......................................................................................................... 25

OTHER CONSIDERATIONS ....................................................................................................................... 26

PROJECT DESIGN .............................................................................................................................. 26

DESIGN 1. .......................................................................................................................................... 26

DESIGN 2 ........................................................................................................................................... 27

DESIGN 3 ........................................................................................................................................... 29

MASS BALANCES.................................................................................................................................. 30

PROJECT EVALUATION ..................................................................................................................... 32

DESIGN SCHEDULE ........................................................................................................................... 33

TIMELINE ........................................................................................................................................... 33

START AND FINISH DATES....................................................................................................................... 36

NON-ROUTINE AND ROUTINE TASKS ......................................................................................................... 36

RESOURCE CONSTRAINTS ....................................................................................................................... 37

ACCOMPLISHMENTS AND FUTURE CONSIDERATIONS ..................................................................................... 37

CONCLUSION ................................................................................................................................... 39

REFLECTIONS ................................................................................................................................... 40

APPENDIX A ..................................................................................................................................... 42

LIST OF FIGURES................................................................................................................................... 42

FIGURE 1. DIFFUSION SIMULATION. ................................................................................................................... 42

FIGURE 2. DRUG KINETICS MODEL. .................................................................................................................... 43

FIGURE 3. TWO COMPARTMENT MODEL OF DRUG KINETICS. .................................................................................. 43

FIGURE 4. GASTROINTESTINAL TRACT (MARIANA RUIZ VILLARREAL, 2006). ............................................................. 44

FIGURE 5.ANATOMY OF THE STOMACH. .............................................................................................................. 45

FIGURE 6. DUODENUM OF THE SMALL INTESTINES. ............................................................................................... 46

FIGURE 7. HIGH PRESSUREFILTRATION. ............................................................................................................... 46

FIGURE 8. HOLLOW FIBER MEMBRANE. .............................................................................................................. 47

FIGURE 9. DOUBLE ENZYME REACTOR. ............................................................................................................... 47

5

FIGURE 10. SINGLE ENZYME REACTOR ................................................................................................................ 47

FIGURE 11. SIMPLIFIED BIOREACTOR DESIGN. ...................................................................................................... 48

FIGURE 12. FALL SEMESTER GANTT CHART. ......................................................................................................... 49

FIGURE 13. SPRING SEMESTER GANTT CHART. ..................................................................................................... 50

FIGURE 14. DECISION FLOWCHART..................................................................................................................... 51

FIGURE 15. BREAKDOWN OF CURRENTLY MARKETED DRUGS IN THE UNITED STATES TODAY (COPELAND, 2005)............. 52

FIGURE 16. DESIGN 1. BLOOD STREAM INHIBITION REACTOR. ............................................................................... 53

FIGURE 17. DESIGN 2. PRO-DRUG NON IMMOBILIZED REACTOR............................................................................. 54

FIGURE 19. COMPETITIVE ENZYME INHIBITION. .................................................................................................... 55

FIGURE 20. ENZYME KINETICS OF CAPTOPRIL. ...................................................................................................... 56

FIGURE 21. MASS BALANCE. ............................................................................................................................ 56

LIST OF TABLES .................................................................................................................................... 57

TABLE 1. DESIGN OF ADSORPTION MODELS. ........................................................................................................ 57

TABLE 2.DECISION MATRIX ON ALTERNATE DESIGNS. ............................................................................................. 57

TABLE 3. DESIGN OF ENZYMATIC SYSTEMS FOR STOMACH AND SMALL INTESTINE. ...................................................... 58

TABLE 4. ECONOMIC ANALYSIS. ......................................................................................................................... 59

QUALIFICATIONS .................................................................................................................................. 60

SAMPLE CALCULATIONS ......................................................................................................................... 61

ACID-BASE CALCULATIONS USING HENDERSON-HASSELBALCH EQUATION................................................................. 61

WORKS CITED ..................................................................................................................................... 63

6

TITLE: DEVELOPMENT OF A BIOREACTOR TO SIMULATE DRUG ADSORPTION FROM

THE SMALL INTESTINES INTO THE BLOOD STREAM

PROBLEM STATEMENT {NOT SURE YOU HAVE DEFINED THE PROBLEM}

To improve patient safety in oral pharmaceuticals, the design of a multi-stage bioreactor will be

developed. {HOW?} The design will have a simulated stomach, small intestines, and blood

stream component where drug adsorption will take place. This system will improve

understanding of drug delivery considering aspects such as adsorption, enzyme inhibition, and

reaction kinetics.

BACKGROUND SITUATION

Medicine has provided a source of healing and comfort to people throughout time. With each

new drug released, there is rigorous clinical testing to determine the drug’s clinical uses as well

as side effects. In any clinical trials there are potential dangerous side effects and risks are

posed to the volunteer patient or the animal subjects. To limit the risks to patients, a

bioreactor simulating the changes in the stomach and the absorption/adsorption in the

intestines should be developed. Beyond just the prevention of these dangerous practices, the

pharmaceutical industry could benefit by rapidly increasing experimentation of new drug

possibilities, or document the effects of different drug combinations and observe the

absorption of the intestines in a non-harmful or intrusive way. This design could serve as a

predictor for all new drugs coming up the pipeline without any human testing. The successful

design would represent a significant cost savings for the company through a reduction in

insurance cost. The bioreactor representation of the stomach, small intestines, and absorption

into the blood stream would make this possible.

CONNECTION TO CONTEMPORARY ISSUES

Currently in our society, our bioreactor design will deal with issues such as: human and animal

testing, PETA, drug manufacturing and experimentation, and medical advances. Currently the

7

cost of prescription drugs is extremely high and sometimes unaffordable for the middle class, so

a successful bioreactor design could potentially reduce the cost to consumer. With the baby

boomer generation reaching retirement age, the prescription drug cost problem is only going to

affect more and more Americans. Not to mention the supply and demand problem that will

occur when more Americans retire than any other prior generation.

This design could potentially improve the public representation of a drug company. When

money is invested in this, it could be portrayed as a commitment to the safety of the consumer.

When drug companies have to deal with the problem of removing drugs off the market (when

determined unsafe when reevaluated by the FDA) our design could provide a welcome change

of pace. Perception of a company’s commitment to safety could lead to great market share and

greater profit margins.

SCOPE OF WORK

Justification for Research

Currently, clinical trials represent between 30 and 50% of the total development costs of any

particular drug. Clinical trials are the stage where human testing actually takes place (as well as

rat testing), and is towards the end of the drug development. This represents a monetary value

of 50 to 300 million dollars, widely varying according to the type of drug.

For this reason, our bioreactor design could potentially significantly reduce this initial and

significant cost to the drug manufacturer and move the product into the market more quickly.

The design would do so by offering more information to the pharmaceutical company,

regarding drug delivery, before clinical trials ever began. Essentially the same information

acquired through blood samples (from a volunteer patient) could potentially be given by the

various stages of our bioreactor design. Less human testing leads to less insurance cost paid by

the drug manufacturer, needed to protect them in the event of a catastrophe of in human

testing (Hughes and Turner, 2002).

Objectives

8

1. Increase patient-based drug testing safety This is an indirect objective

2. Better understand drug delivery (Measureable?)

3. Design and model intestine/bloodstream bioreactor

Deliverables

1. Specific Bioreactor Design

2. Mass Balance

3. Economic Plan

The deliverables were chosen based on what information a company may need to invest in the

artificial stomach and small intestine. An investor would need to know that the design is

feasible, that it has correct assumptions during the design, the measures of success, and most

importantly how much the product will cost.

DESIGN CRITERIA AND CONSTRAINTS

The determination of whether or not the chosen design (all designs mentioned in alternative

designs section) is successful is dependent on a number of criteria. With the cost of clinical

trials making up 30-50% of the overall cost for a drug’s development, it won’t be particularly

challenging to offer a cheaper alternative. Currently drug companies pay from 50-300 million

dollars in their clinical trials, and though it’s a high cost, it is a necessary cost to ensure safety

and meet the regulations from the FDA. This project is also unique in that it aims to increase

safety in drug testing, specifically for the patients volunteering. The question can reasonably be

raised in what price you are willing to pay for safety? This point is raised not to start an ethical

discussion, but to draw attention to the point that we aren’t developing a product to compete

in the marketplace. Currently the idea of a bioreactor, of any shape or form, is at best in the

research and development stage in the United States. To this team’s knowledge, no

bioreactors are in use today by pharmaceutical companies for the purpose of modeling the GI

tract. Competition would cloud the overall justifiable cost argument, but it is relatively unclear

just who the competition is at this point.

9

Physically {what happen to size?}, the specific design of the bioreactor will be constrained to

match to human body as closely as possible. Therefore it will need to be 37 degrees Celsius,

which can be controlled by insulation and heat application. It will need to be able to withstand

the strong acidic environment of the stomach. It will also need to be partitioned to be the

same size as the stomach and small intestine. The reactions that occur in the stomach will need

to be emulated in the stomach section and the enzymatic changes will need to be accounted

for in the small intestine section. The adsorption will also need to occur at similar rates as the

human small intestine.

LITERATURE REVIEW

General Information

In research and development, companies of any discipline are always working to improve their

technology. Technology developed to increase safety is unique; one of the few cases where

improving efficiency is second hand (to overall safety). In this design, safety and efficiency go

together. Effectively simulating the pharmacokinetics without having to risk a patient’s life, is a

huge advance in efficiency. Insurance and legal costs are significantly decreased now that a

machine is taking the risk that a human once volunteered to do. To improve safety of drugs, as

well as decrease patient based testing, our design aims to provide a simulation that has yet to

be well established in the industry.

This design is unique in that most of the research being done in order to simulate drug delivery

actually uses living tissues or organs. For example, Fortn et al. (2001) has successfully replicate

artificial perforations by means of a bioreactor to create gastric mucosa and fibrous tissue. This

design uses a bioreactor to do the simulation. The bioreactor developed will simulate the

stomach and small intestines, as well as the blood stream. One possible way to simulate the

diffusion of a molecule into the small intestine (Figure 1), is to use a filter design (Stefanyk,

2008). Even though the small intestines and stomach represent a large portion of the digestive

system, important components are being left out. Digestion begins in the mouth. Weisbrod

insists that the mouth should be included for simulation of the digestive tract. There are even

10

ways to have drugs pass through the stomach unscathed (Weisbrod, 2008), which raises the

consideration of replacing the stomach with the mouth.

Drug Adsorption

In terms of drug safety, frequently lab tests are done on a small scale to simulate different parts

of pharmacokinetics (literally the movement of drugs). Passive diffusion is predominant for

most forms of drugs. In addition, all forms of drugs must pass through several forms of

biological membranes which are composed of mainly lipids and proteins. Traditionally, the

ability of the drug to permeate across various biological membranes is evaluated by measuring

the partitioning of the drug in octanol and water systems. Octanol is a good representation of

lipid materials. Partitioning is simply the ability of a compound to distribute in two immiscible

systems. Partitioning is often a function of pH, among other things such as temperature. This

current work of partitioning using octanol as the medium will be heavily considered in

development in the bioreactor (Ghosh et al., 2005).

Typically, poor oral drug absorption has been attributed to having poor solubility or poor

membrane permeability (at a given pH). Also, physiology as well as chemistry are the two

predominant factors looked at for drug absorption. However, a new approach to

understanding drug absorption deals with the actual drug’s metabolism in the intestine. The

consideration of a counter-transport process via enzyme is also being considered. Both of

these drug interactions are believed to have a significant impact on the drug’s absorption. The

availability of a large number of drugs is believed to be impacted by these two processes (Benet

et al., 1996).

Passive diffusion occurs when there is a concentration gradient in the system. It is the natural

tendency towards equilibrium. Depending upon the concentration gradient, this passive

diffusion might occur in a quick or sluggish fashion at any given time. In the human body, often

the concentration gradient is quite minimal, so this passive diffusion might not occur fast

enough to actually make a positive impact on the body. Since the human body is incredibly

efficient, often the use of attractive or repulsive forces (often hydrophobic or hydrophilic) are

11

used to speed the diffusion of a molecule through a biological membrane. These are all forms

of passive transport.

When passive diffusion cannot provide the necessary rate for molecular movement, there are

several forms of active transport that the body is known to use. In one specific form of active

transport, mentioned by Benet et al. (1996), deals with the counter-transport processes using

enzymes. In all cases, it is worthwhile mentioning that the enzyme doesn’t directly cause any

reaction to take place; it merely plays a role as a catalyst. The human body would not be able

to function without enzymes as catalysts, and when an enzyme is used, an “active” process is

occurring.

Pharmacokinetics

Drug kinetics, meaning literally the movement of drugs throughout the body, is one of the key

points that this design project will address. Tracing the path of the drug can be difficult, and in

many instances the entire system will be simplified as the stomach, small intestine, and

bloodstream (Figure 2) in order to develop mathematical models for it. Two of the most used

models are the one and two compartment system. In the one compartment model, the

assumption is made that the drug reaches rapid equilibrium throughout the body. A good

example of a rapid equilibrium type of drug is Viagra (Stewart et al., 2009). Peak drug

concentrations of Viagra in the bloodstream can be found in as little as 30 minutes. The only

factors that are considered are the drug dose going into the body, the volume of the body for

the drug to rapidly disperse to, and the elimination rate of the drug. This model works best to

simulate an injection of a drug, as the circulatory system can rapidly distribute the drug

throughout the body.

Typically the assumption is also made that the removal of the drug is directly related to current

concentration. This also means that the half-life of the drug is always going to be the same, no

matter what the concentration. Half-life is defined as the amount of time necessary for the

drug to reach half its original concentration in the body. It is an important parameter of drug

models, as it is assumed to be constant throughout the time the drug is taken to complete

removal of the drug (through excretion). The major factor that controls the accuracy of this

12

model is how quickly the drug reaches equilibrium throughout the body. If equilibrium is nearly

instantaneous, then this serves as an accurate model for the drug’s metabolism. The other

model that it is actively used is the two compartment model (Gibson, 1994).

The two compartment model (Figure 3) takes into account the fact that not every part of the

body has the potential to eliminate a drug. Drug elimination is often studied in drug models

because adsorption is often more difficult to measure. If the drug is not being eliminated, then

it is most likely interacting with some components of the body. If not part of the GI tract, then

the drug has obviously been absorbed through a biological membrane. Most of adsorption

takes place in the small intestines, and minimal adsorption takes place in the stomach and

mouth. Modeling adsorption in this design project will strictly deal with the small intestines. In

conclusion, when testing humans measuring the removal of the drug is simpler; there is no

invasive testing needed and no guesswork of where the drug might be concentrated in the

body. Invasive testing is done, but it is much more time and effort intensive. A bioreactor

design is being developed to reduce the amount of invasive testing.

The major forms of drug removal are no different than any food, excretion via feces or urine.

For this reason, a compartment is taken into account for all areas of the body that cannot

eliminate the drug. This model is much more appropriate for simulations with the small

intestines and stomach, as neither can directly eliminate a drug out of the body. In this model,

more factors can be taken into account. The factors considered are: drug dose, rate of drug

delivery to non-excreting compartment, rate of drug delivery to the excreting compartment,

and the rate of drug removal. Areas of the body that are highly permeable, such as your lungs,

heart, or glands are represented by the excreting compartment. Areas of the body that are not

very permeable, such as your muscles or skin, are generally represented by the non-excreting

compartment. In the two compartment model, in addition to modeling the change of

concentration over time (like the one compartment model), the area under the concentration

time curve must be taken into account. This area describes the overall load of the drug in the

body. This “bioavailability” is an indirect representation of the therapeutic value of the drug

(Gibson, 1994).

13

Kinetic order of a reaction must also be considered. When the assumption is made that the

rate of drug removal is relevant to the concentration, a first order rate of reaction is assumed.

The two compartment model, widely used in the pharmaceutical industry to explain drug

kinetics, uses a first order rate of reaction. However, when the drug concentration is high

enough, the body will remove of it at a maximum rate until a point, at which it will remove of

the drug in accordance to concentration. When it is removing the drug at maximal rate, the

relationship is zero order (Gibson 1994). Zero order reactions typically turn into a first order

reaction as the concentration gradient decreases over time.

The two largest groups of enzyme interactive drugs are pro-drugs and enzyme-inhibition drugs.

Nearly half of all currently marketed drugs are enzyme inhibitors (Copeland 2005). A pro-drug

bonds to an enzyme that speeds the reaction necessary for the substrate to change to a usable

drug molecule (it changes form). An enzyme inhibitor doesn’t typically change in substrate

form; it simply slows down a reaction that was already going to occur in the human body.

Currently there is more research on enzyme inhibiting drugs as opposed to pro-drugs, as well as

more drugs on the market.

Enzyme inhibiting drugs will be used in this design because of greater available information and

because of they will be more readily measureable in the outflow from the bioreactor. The

inhibitor is a known substrate, and since it doesn’t change (in detectable form) using

chromatography techniques, we will know what to measure for in the outlet of the reactor.

Given enough time all of the inhibitors will elute out of the small intestine design. But with the

immobilized enzymes in the column, they should elute out in a measureable quantity and a

respective disassociation constant should be able to be calculated. To determine the contents

of the outflow, samples will be taken at specific time intervals to determine how much enzyme

interaction is taking place in the small intestines. The time intervals will have to be chosen at a

later date. Depending on the drug chosen, a specific naturally produced target enzyme will be

immobilized in the column.

Captopril Kinetics

14

Peak reduction of blood pressure occurs roughly 60 to 90 minutes after initial dosage of drug

(Stewart et al, 2009). It has been determined that to reduce the reaction velocity by half, a

concentration of 4.98 x 10-10 M is necessary (Copeland, 2005) in the bloodstream. Specifically,

the reaction that is being slowed by Captopril is the combination of angiotensin I with ACE to

produce angiotensin II. This can be seen in Figure 18. angiotensin I is the substrate and ACE is

the enzyme. The inhibitor, is our drug, Captopril. The half life of the drug is 30 minutes upon

entering the blood stream, so the body is quite capable of readily removing it (Stewart et al,

2009). Due to the fact that analytical chromatography is a slow process in general, this design

will not seek to remove of 50% of the drug in 30 minutes of time.

The rate constant for the forward reaction of the enzyme combining with the substrate is 1.2 x

106 M-1s-1. This is commonly referred to as k1. The rate constant for the forward reaction of the

enzyme combining with the substrate is 2.55 x 106 M-1s-1. This explains to you that at initial

conditions, if the concentration of the substrate is the same as the concentration of the

inhibitor, the enzyme will not only have a greater affinity to the inhibitor but additionally the

reaction will proceed at less than half the possible velocity. Additionally, it can be observed

that the overall rate of the reaction is certainly forward by looking at the rate coefficients.

Whether the inhibitor is added or not the reaction, it will proceed. The rate that the reaction

precedes is what is impacted by the inhibitor, and drug, Captopril. The forward rate coefficient

of the enzyme combining with the substrate is, as previously mentioned, 1.2 x 10 6 M-1s-1. With

the reverse of that being only 4 x 10-4 s-1, the forward reaction is 3 x 109 more powerful at initial

conditions (Copeland, 2005)!

The body cannot have this reaction proceeding so quickly at all given times (reaction would be

out of control) so the body uses allosteric effects regulate or moderate the reaction (Campbell

et al, 2006). The substrate and product of our design’s reaction, as mentioned previously, are

Angiotensin I and Angiotensin II. However, there are several other intermediates that

additionally are made to regulate the blood pressure. The eventual product that impacts blood

pressure is aldosterone. However, angiotensin I and angiotensin II impact blood pressure as

well, as they effect the production of aldosterone. Captopril doesn’t inhibit the production of

15

aldosterone, but instead angiotensin II. For this reason, or design simplifies the system and

only deals with the angiotensin I to angiotensin II conversion. The significance of all this is that

the catalytic rate coefficient, kcat, is dynamic. Kcat describes the rate that the enzyme substrate

complex converts to the product and enzyme. The enzyme responds to the product

concentration (aldosterone) and the product works as a negative effector. A diagram of the

enzyme kinetics can be seen in figure 19.

Oral Drug Information

Orally taken drugs are the direct focus of this bioreactor simulation. Protein based drugs are

not significant in this simulation as they have not yet been developed to be able to tolerate oral

dosages. This is because they are particularly susceptible to degradation, especially if they

were to be exposed to the pH of the stomach. Much of the drug technologies on the market

today currently rely on a controlled release mechanism. There are a few different levels of

controlled drug release, and in the spirit of the current jargon, there are six different

generations of it. Generations one through three will be most heavily considered for

development products to be potentially used in the bioreactor. In many drugs on the market

today, the flatter the plasma drug concentration over a period of time, the better. Unlike

modern day medicines that might be site specific, such as protein based drugs, none of these

drugs are at that level of sophistication. Once the drug has entered the body orally, it will

follow natural biological paths into the rest of body through the bloodstream as shown in

Figure 2. Likewise, once drugs have entered the bioreactor that is under development, there

will be no control over where the highest concentration of drug will specifically go. This is

doubly frustrating as it is very difficult to measure the concentrations of any drug in different

parts of the body after it has been ingested (Ghosh, 2005).

Drug tablets can be made of surprisingly numerous materials, which could involve: polymers,

sugars, and gelatins. Depending on the purpose of the drug, one of the many options can be

chosen. Though the tablet coating process can be overall difficult to master (for a given drug),

the benefits of solid tablets are substantial. They can be accurately measured for specific

dosages, they are easily transported in bulk, and they are generally more stable than their

16

liquid cousins. Understanding the materials that coat a given drug will allow for the prediction

of where the drug will become active, and how it will reach its given destination (Ghosh, 2005).

Another form of oral drug dosage is a liquid. Solutions, suspensions, and emulsions are the

main forms of orally taken liquid drugs. The predominant solvents that are added to the drugs

are water and alcohol. There are many advantages and disadvantages of oral liquids. Some of

the advantages are: the active agent is homogeneously distributed in the product and the agent

doesn’t need to be dissolved and therefore can have faster therapeutic response. Some of the

disadvantages are: the active agents are often susceptible to chemical degradation and the

solution is often susceptible to microorganisms (Ghosh, 2005).

Captopril Information

Captopril was one of the first blood pressure regulator drugs to ever hit the market, and it was

approved by the FDA in 1981. Early research actually extracted ideas for such a drug by

studying the venom of snakes. As it turns out, snake venom often contains components that

inhibit the conversion of Angiotensin I to II (Case et al, 1980). It is still widely used today for

treatment, and as almost 74 million Americans have hypertension, will likely remain popular for

years to come. It is an enzyme inhibitor, making it among the most common class of drugs

being marketed today (Figure 14). It was chosen as the drug for this design to model because

of the relative simplicity in comparison to other drugs. Pro-drugs, another common type of

drug used for high blood pressure treatment, will change forms at various stages in the body

until its eventual use. This makes pro-drugs an unattractive option for the design, because

what is introduced in the system cannot directly be measured for. Since Captopril remains the

same throughout introduction and excretion out of the body, it was chosen because it would be

easier to measure for.

Captopril works by inhibiting one specific enzyme, ACE, and nothing else. It inhibits one step of

the multiple steps that take place in our body to regulate blood pressure. Some enzyme

inhibitors show affinity to multiple enzymes, further complicating the system, making Captopril

again a logical choice. In short, choosing Captopril allowed for a more feasible design that could

produce more measureable and repeatable results. It was also chosen because of the

17

popularity of enzyme inhibiting drugs on the market today. The goal of this design project is to

effectively simulate Captopril, but if this can be accomplished, the design can predict the

kinetics of a drug before ever entering a volunteering test subject.

The reason that Captopril works is because of the impact that Angiotensin I and II have on the

body. Angiotensin II is a vasoconstrictor that is three times more powerful then Angiotensin I

(Copeland, 2005). As will be explained later in the mass balance, the majority of the Captopril

never accomplishes this goal of inhibiting the production of Angiotensin II, but as it turns out

the drug doesn’t have to. The goal of Captopril is to reduce blood pressure, not cease it. If

Captopril was 100% effective, this would be of no use to medicine as it would result in patient

death. Captopril moderates the body’s natural regulatory mechanism called the reninangiotensin system. Rate coefficients of Captopril can be found in figure 19.

Stomach and Small Intestines Anatomy

GENERAL

The digestive tract in the human body is composed of many different major parts including the

mouth, stomach, small intestine, large intestine, pancreas, and liver (Figure 4). Even this is not

the entire system, and for the purposes of this design there will be even more simplification.

The stomach’s main purpose is the mechanical and chemical digestion of food. It does use

pepsinogen to form pepsin to begin the chemical digestion of proteins, but the majority of the

enzymatic digestion occurs in the small intestine. Besides the pepsin in the stomach and the

amylase in the mouth, the section of the small intestine called the duodenum uses enzymes

secreted locally and those transferred from the pancreas and liver to break down lipids, starch,

sugars, and proteins. The enzyme secretion is controlled by a variety of hormones that can

start and stop the secretion process. Bile salts from the liver are also used in to emulsify fats

for easier decomposition. Beyond the duodenum the rest of the small intestine absorbs the

nutrients like amino acids, maltose, and fatty acids. The large intestine is mainly used to

reabsorb water and salts (Hopson, 1992). For the purpose of this design the stomach and the

small intestine are the only major locations that will be focused on.

18

The movement through the tract called peristalsis is mainly controlled by muscle contraction.

Two different sphincters exist on the stomach, one at the entrance and one at the exit. The

cardiac sphincter at the opening is controlled by the swallowing motion from the esophagus as

the food is moved into the stomach. There the food becomes chime and exits through the

pyloric sphincter at an average rate of about 5 ml per sec in a squirting motion. This flow rate

will be used in the reactor to be developed. This is controlled by muscle contraction, but unlike

the cardiac sphincter is not done so consciously (Mader, 1994).

In creating stomach/small intestine bioreactor, the mouth and large intestine may be ignored.

While the secretions from the pancreas and liver can be simulated, the majority of the focus

will be on the stomach and small intestine. With the way food flows through the stomach and

small intestine, the best kind of reactor will be a batch reactor to better simulate the stomach.

The path from the small intestine functions more like a continuous reactor, the batch process

from the stomach will adequately simulate the process (Purves, 2004).

STOMACH

The lining of the stomach produces approximately 2 liters of gastric fluid daily, composed

mainly of: pooled hydrochloric acid, mucus in the layers, and pepsinogen secreted into the

system (Figure 5). The acidic nature of the stomach can change break down lipids by

peroxidation (Kanner, 2001). Proteins are one of the products largely broken down in the

stomach by pepsin created from the reaction of pepsinogen and HCl, though not absorbed.

This is largely the reason why protein based drugs have yet to advance to the level of being

administered orally. Enzyme sources, their location that they are active, and the products that

they break down are well known and studied (Starr, 2004). For example Lactase has been

widely studied in its relation to lactose intolerant people. Many people exhibit problems with

milk’s sugar lactose. Lactase, produced in the cells of the small intestine, has been studied and

shown to break down lactose to aid in digestion. While to people mentioned in National

Digestive Diseases Information Clearinghouse have problems with lactase other people who

have lactase working in their system have no trouble with milk.

19

SMALL INTESTINE

The small intestine is made up of three specific parts, the duodenum, the jejune, and the ileum.

Most of the reactions that occur in the small intestine occur in the duodenum. The pancreatic

duct (Figure 6) leads into this section with enzymes from the pancreas and liver. Most of the

adsorption that occurs in the small intestine occurs in the jejune and ileum. Some adsorption

does occur in the duodenum though, and in total the surface area where adsorption can occur

is about 550 square meters (Purves, 2004).

Due to the fact that recreating 550 square meters in a design to fit in a lab space is nearly

impossible, this design will not incorporate such a large surface area. The human body creates

such a large surface area by having a great deal of overlapping folds. Having overlapping folds

and a consistent experimental runs is highly unlikely and the technology simply does not exist.

For this design, an area of 1 m2 square meter will represent the small intestines.

Transmembrane pressure will be used to overcome the fact that the area for diffusion to take

place is going to be considerably smaller. The surface area will be considered appropriate if

expected diffusion rates are produced.

MICROORGANISMS

There are several microorganisms in the digestive system, yet only a few will be considered in

this simulation. This is because some of the microorganisms in our body are responsible for

producing enzymes that are needed for digestion. The only natural flora of the stomach is the

microorganism Heliobacter Pylori that can set up the housekeeping in the stomach because of

its strong flagella and urease enzyme which can split urea into ammonia and CO 2. The

ammonia dampens the acidic environment making it feasible to live in the stomach. Also food

can pass through the stomach due to a food bolus in certain cases (Daniel, 2008). It is nearly

impossible for any other microorganism to survive in such harsh conditions of the stomach with

the pH around 2.

The small intestines have slightly more microorganisms in them. The pH changes to nearly 4 or

5. This allows the bacteria that are Enterococci and Lactobacilli to survive in the environment.

As the small intestines continue more bacteria can survive (Brock, 2006).

20

OTHER CONSIDERATIONS

A food’s effect upon an impact of a drug can be significant. However, they are difficult to

model. Biological membrane pore size can be altered with red meats and it can allow for more

toxins to be absorbed into the system. Gorelik et al. (2008) discourages us from following food

digestion with the system. This could be a future change we could alter our model at a later

time.

Safety and Regulations

Safety in pharmaceuticals fights impossible odds to get a medicine with no chance of any side

effect. “Every effective medicine has a balance of benefit to risk and anybody taking or

prescribing a medicine, to obtain the anticipated benefit, must recognize and accept the

concomitant risk of an adverse effect” (Inman, 1986).

FEDERAL REGULATIONS

There are two organizations in the US who influence drug safety. The first organization is the

food and drug administration (FDA) and the second organization is the drug regulatory

authorities (DRAs). Ways these companies improve drug safety are by modifying the

formulation of the drugs to decrease gut irritation, aid absorption, or alter the bioavailability in

order to produce more consistent and more appropriate blood levels (Inman, 1986). The words

‘reformulations of drugs’ are strongly discouraged in drug safety improvement. The DRA would

prefer a specific area to be mentioned for drug safety. Reformulation could cause a complete

new set of side effects. The largest area that the DRA pays attention to is the Post Marketing

Surveillance (PMS). This implies that the industries must follow any ideas that relate to safety

as long as they are practical and realistic.

Prescriptions drugs have strict regulations listed due to the potential to do harm if used

incorrectly. The number one problem with prescription drugs is the prescription drugs are

being diverted for illegal uses. The Drug Abuse Warning Network (DAWN) is in charge of

making sure prescription drugs go to their proper use. It is nearly impossible to get addicts off

of prescription drugs. Therefore there are regulations on dosage, labeling, and warnings. Any

positive or negative effect known about the drug must be listed on the bottle.

21

ANIMAL TESTING

Federal regulations have strict rules on animal testing. Animal testing costs amount to

approximately $136 billion per year (Stare and George, 2008). In animal testing are there are

25-50 billion animals killed every year by drug testing. Most of these animals are rats and

hamsters. Half of those tests are done by cosmetic companies. Even the tests that are

successful have harmful effects for 61% of the people who are tested on. This is due to

enzymatic differential in animals versus humans. For instance, cats do not have the enzyme to

digest ibuprofen (Paws, 2008).

GLOBAL ENVIRONMENT

Regulations of medicines in Europe started shortly after the thalidomide affair. The

thalidomide affair was a toxicological disaster caused by several ‘competent authorities’ which

allowed the drug to make the market. The European Union was established to have a common

market for drugs on the market. This organization is decades behind the FDA which was

established in the US in the early 1900s but the EUs branch for drug safety still has very similar

regulations (Mulder, 2006).

SAFETY ASSESSMENT

Good Laboratory Practice (GLP) was developed in the 1970s to ensure quality. All US and

European countries should meet GLP standards. The only portion of pharmaceuticals that do

not follow GLP standards would be the developmental pharmacological section. (Mulder, 2006)

When assessing if the products would be safe for humans there are several different qualities

that each product must pass. For instance if it was a Vaccine, it should have minimal side

effects. Whole-cell pertussis vaccine was taken off of the market due to side effects including

convulsions, persistent, and screaming. If the product was a sleeping pill it would have a strong

effect on blood pressure. It could be pulled off the market if there was a high risk of patients

developing a dependence on the drug by taking a sleeping pill or other drug every night

(Mulder, 2006).

If there was a harmful drug identified, patients must know what medicines they were taking.

The best way to identify these drugs would be leaving them in their original packaging with

22

warning labels shown. If the drugs were not in the original packaging they would be considered

dangerous because the consumer would not be informed of active ingredients. (Inman, 1986)

The ICH, the International Conference on Harmonisation of Technical Requirements for

Registration of Pharmaceuticals for Human Use, and The ICH M3 guidelines specify that before

the first use in humans the following data should be present.

Safety pharmacology with respect to vital functions, cardiovascular, central nervous

system, and respiratory system.

Information on absorption, distribution, metabolism, and animal metabolic pathways.

Single-dose (acute) toxicity in two mammalian species. A dose-escalation study is

considered an acceptable alternative.

Repeated-dose toxicity. Tests should be done on rodents and in non-rodents.

Local tolerance should be studied, preferably in connection with other toxicity studies.

Genotoxicity data from in vitro tests: evaluations of mutations (bacterial mutagenicity,

Ames test) and of chromosomal damage (e.g. mouse lymphoma) are generally needed.

The FDA has developed the “ScreeningIND” (IND = investigational new drug) to take a volunteer

to test the pharmacokinetics in the same person before placing the new drug into their system.

Some tests cannot be altered when testing. For instance, testing maximum allowable dosage

will be tested on dogs rather than humans. (Mulder ,2006)

ENVIRONMENTAL CONSIDERATIONS

The removal of chemical wastes from Virginia Tech is a streamlined process. Similar regulations

could take place in other locations or facilities. The containers for the waste are provided from

the university, as well as the labels. Waste removal is prompt, and only requires a quick phone

call. Of all the wastes in our design, only one item is biological in nature. The enzymes that will

be used are obviously biological products. However, enzymes do not fall in the category of

biological hazards (Egan, 2008). The only significant environmental hazards in this project are

the acids, and the current infrastructure setup at Virginia Tech (VT EHSS, 2008) is experienced

and capable of handling this task.

23

The Hazardous Waste Disposal Program (a division of Environmental, Health, and Safety

Services) explains in detail how to handle the disposal of hazardous chemicals. This particular

design calls for the use of hydrochloric acid, a major component of gastric fluid, to be used.

Instructions for disposal of such acids are as follows:

Wastes should be in sealed containers without any sign of leakage

The container should be full but not overflowing

The maximum container weight is 22.7 kg (50 pounds) and volume is (18.9 liters) 5

gallons

Stored waste should be in appropriate storage cabinet, according to the chemical

compatibility

All containers must be labeled with hazardous waste label and the requested

information all completed

Waste label information of: Department, Building, Room, Name, Phone, Size, Proper

chemical name, Components of waste and their percentages, pH, Written and signed

name

Schedule a waste pickup

Send label waste copy to Environmental, Health, and Safety Services

ALTERNATE DESIGNS

Adsorption Models

The adsorption models shown below are all representing the small intestine. With the small

molecule drugs as the focus of the project, most adsorption takes place in the small intestine.

In Table 2 shown below you can see some of the advantages and drawbacks of the models.

A high pressure filter is our first and most simple design. As shown in Figure 7, this model

places the contents of the stomach on the left side of the filter and places the contents of the

bloodstream on the right side of the filter. There is a mechanical agitator on the left side of the

filter as well to increase the speed of filtration.

24

A hollow fiber membrane is a strong candidate for representing the small intestine. In Figure 8,

the hollow fiber membrane is shown in a cylindrical nature to accurately represent the physical

nature of the small intestine. One of the drawbacks of the hollow fiber membrane is the

membrane will not have uniform filtration when modeling. However, this can be accomplished

by increasing the pressure in the filter and adding a recycle element to the reactor. There are

physical and chemical constraints to the membrane, but those constraints are high heat and

corrosive substances which do not play a factor in our model.

Stomach/Enzymatic SI Models

For modeling the stomach and small intestine several things should be taken into account. For

instance, the stomach is a pretreatment phase. Due to the low pH and very acidic environment

of the stomach, the small molecule drugs are designed to pass through the stomach and get

adsorbed in the small intestine. Most of the enzymatic reactions happen at the beginning of

the small intestine in the duodenum. The list of advantages and drawbacks are shown below in

Table 3.

The double enzyme model (DEM) will be a realistic model for our system. This model will

accurately represent the stomach and small intestine from an enzymatic level. This figure is

shown by Figure 9. This is simply a packed bed of immobilized enzymes that will react with the

small molecule drug. If the drug needs a longer reacting time there could be a recycle portion

of the reactor added to the end of the packed bed and returning it to the beginning of the

column. Unfortunately, one drawback is that not all of the enzymes will play a factor in the

model.

The single enzyme model (SEM) will be less expensive than the double enzyme model. The

single enzyme model only accounts for the enzymes in the small intestine. This is a fair

assumption due to the fact that the enzymes in the stomach do not play a role in the

breakdown of the small molecule drugs. The drugs are typically designed to pass through the

stomach so it can make it to the adsorption stages of the small intestine. In Figure 10 the

model is very similar to the double enzyme model except there are no enzymes in the stomach.

This will reduce the cost of the system.

25

The majority of design analysis of this project will be performed by chromatography analysis.

Specific times that samples are taken from the bioreactor will have to be recorded. Samples

would have to be taken at the exit of the model as well as within the model. These specific

locations (where samples will be taken) will be explicitly defined next semester. Different

components and their concentration could be determined by anion exchange chromatography,

with the knowledge that different compounds of the drug measured for will elude at different

times. A spectrophotometer (commonly embedded within the chromatography model) would

also be necessary. This would provide the information necessary to construct the two

compartment model

Other Considerations

A Pig Stomach could be a very positive way to represent the model due to the stomach being a

living system. This system would include all of the natural flora, enzymes, and proper filter size.

However, there are several drawbacks that include a onetime use for each stomach, variability

in each stomach, and possible ethical issues in taking the stomach from the pig. It would also

be difficult to maintain a living system.

PROJECT DESIGN

The best design choice will be combining the single enzyme model with the perforated column

membrane. This model is shown below in Figure 11 and accurately represents the GI tract for

small molecule drug adsorption. In the GI tract the drug must pass through the stomach, then

pass through the duodenum where the drugs will be broken down, then finally be adsorbed

from the small intestine into the bloodstream. Due to the mechanical nature of this design, it

follows only the theoretical path of the GI tract. The full model shows any enzymatic or

chemical breakdown of drugs along with the adsorption stages of the GI tract.

Design 1.

Since this design follows the path through the GI tract it will start with a stomach simulation.

The stomach tank would store a working volume of 2L of HCl, salts, and the capsulated drug.

26

The tank will be held at a heat of 37 ˚C to properly simulate the heat of the body, and the pH

should be kept around 1-2. Instrumentation such as pH and temperature regulators would be

implanted here to ensure proper conditions throughout the process. After a mixing tank, a

peristaltic pump will pull out about 5 mL/s of the slurry and send it to the perforated column

membrane. The retentate from the membrane would be the waste of the drug. This would be

excreted from the body through the GI tract without affecting the body. The permeate from

the membrane would be the adsorbed drugs and enzymes that will have an effect on the body

in the blood stream. The separation is shown in Figure 1. The assumption in this model is the

enzymes are inhibited in the blood stream. Since this project would use Captopril, an orally fed

high blood pressure medicine that affects the blood cells, the assumption would be valid. To

show the enzymes in the bloodstream there would be an immobilized enzyme column to

simulate the interaction. Once the drug passed through the enzyme column, affinity

chromatography would be used to measure the amount of drug that would interact with those

enzymes. This design is shown in Figure 16.

Assumption: Enzymes are absorbed into and interaction takes place in the blood stream.

Difficulties: Though enzyme immobilization would save on enzyme costs (enzyme would be

reused), it would be difficult to modify the concentration of the enzyme. Enzyme

immobilization would have to be done by the company that the affinity column would be

purchased from, and this would take time and significant cost. (How much more?)

Recommendation: Due to the lower cost overall (enzyme cost would be the most significant

cost in this design) and simulation of food inhibition as well as enzyme drug binding in the

column, this design does receive our top recommendation. Pharmacokinetics could most

effectively be studied with this design; however, the other two designs could simulate portions

of what this design could with less possible investment. Depending upon what the client’s

exact interests would be then design 1, 2, or 3 could all be valid options.

Design 2

27

This design will work well with a pro-drug or enzyme inhibitor {Need to differentiate – Pro-drug

is mostly a protein drug}. A pro-drug requires a specific enzyme to change form and produce a

product. This product functions as a drug in the body. The fact that it can work with either

type of drug is an advantage to this design.

There will be a 2 liter tank containing a few salts such as KCl and NaCl, and a strong

concentration of HCl. The pH will be kept between the range of 1-2, and this tank will represent

the stomach. The temperature of the tank will be 37°C, regulated by a heat exchanger. The

encapsulated drug will be introduced into the stomach and then be dissolved. The stomach will

be removing the gastric fluid at a rate of 5 mL/s.

The second compartment will represent the small intestines. This tank will have to have a pH of

4-5 and be maintained at body temperature. The gastric fluid containing the drug will be mixed

with a buffer solution as well as a sugar solution containing enzymes. These will be allowed to

mix in the second compartment, and will allow sufficient time for enzyme drug interaction, and

flow to the next compartment.

In the third compartment, there will be a perforated cylinder membrane. The enzymes are

quite large in comparison to the small molecular weight pro-drug, and the products of the prodrug; therefore separation will occur. The pro-drug and its products will permeate through the

filter, and the enzymes will be forced to pass through as retentate.

The permeate will be collected and anion exchange chromatography will be run. Due to the

different charges of the product and the pro-drug, these two molecules will elute at different

rates. The pro-drug and its product often have different charges in the human body because to

cross a membrane, the product might have the proper properties to diffuse, but the pro-drug

does not have the right charge and will be forced to exit into the large intestines. This design

can be seen in figure 17.

Assumptions: The pro-drug will be assumed to have sufficient time to react with the enzymes

when in compartment two. Not all of the pro-drug will be converted into its products, just as in

28

the body, but a comparable level of conversion will occur. There are no outside interactions in

the process that have not already been mentioned.

Difficulties: This design would be exceptionally expensive to implement. Enzyme cost would be

extraordinary, and where other designs would be able to reuse the enzymes (as they are

immobilized, this design would require a separation process to recycle the enzymes. This would

be necessarily easy, as the enzymes would have to very well purified, otherwise they would

contain contents of the pro-drug and its product and would likely influence the results of

product produced that we measure in our chromatography step.

The second challenge of this design is achieving a comparable reaction rate in the second

compartment with the enzymes and the pro-drug. This would be nearly impossible, and finding

conversion rates of any type of drug with an enzyme is not readily available information. The

body cannot possibly achieve 100% conversion of the pro-drug into its product, and neither can

this design. However, matching the conversion rate of the body with our design would

challenging and expensive.

Design 3

The stomach is simulated by a tank of hydrochloric acid with a working volume of 2 liters. It is

kept at a temperature of 37oC by a heat coil, and a pH sensor is linked to acid and base

reservoirs to keep the pH between 1 and 2. A slurry of food and drug is added to the tank to

simulate ingestion. The base reservoir will be used as a buffer solution to mix with the slurry

upon entrance into this section to better simulate small intestine conditions. This slurry, after

being well mixed, is pumped out at a constant rate of 5 mL/s into the duodenum section of the

design. The majority of adsorption in the small intestines takes place in the duodenum. This

section has immobilized enzymes placed into the packed column to interact with the drug and

cause the desired enzyme substrate binding. The contents continued through into the next

section representing the rest of the small intestine. This section is composed of a hollow fiber

membrane to separate the slurry from the drug. The slurry passes out as the retentate along

with some buffer solution and can likely be recycled. The permeate is composed of the drug

and is sent to an affinity chromatography unit to separate out how much drug is left. By

29

determining how much drug permeates out it would be possible to determine how much is

adsorbed and how affinity changes with food interaction. This design can be seen in figure 18.

Assumptions: There are no outside interactions with the process not already mentioned.

Enzymes are not adsorbed into the blood stream but are used inside the small intestine.

Difficulties: There could be problems forcing the slurry through the packed column. It may not

flow through and could cause accumulation and fouling. The major limitation of this model is

that it will likely not be able to demonstrate food’s inhibitory effect upon Captopril in

decreasing adsorption. This design is also fairly unrealistic, as enzyme substrate binding

(Captopril and ACE) takes place in the blood stream, not the small intestines. This will change

the affinity of the enzyme to the drug. This is one area where design one succeeds, making it

our overall recommendation.

Mass Balances

According to the literature, the average human will adsorb roughly 75% of the overall drug

input into the body through the small intestines (Stewart et al, 2009). This was determined

through carbon-14 labeling. This effectively means that 25% of the drug will never be used and

exits the body as waste. To simulate stomach acid, two liters of 0.02 M HCl will be added into

the stomach bioreactor. This acid will be neutralized by the necessary buffer solution to raise

the pH to nearly 5. This work can be seen in the sample calculations section. A standard

dosage (50 mg) of Captopril will be added to the acid and will flow out of the reactor at 5 mL/s.

When Captopril is taken within 2 hours of a meal, the food greatly inhibits the adsorption of the

drug through the small intestines. To simulate the food in the stomach, 100 g of Carnation

instant breakfast will be mixed in making a slurry. When this is the case, adsorption of the drug

into the bloodstream is decreased to about 45%. Of the drug that enters the blood stream,

only roughly 60% of it will ever interact with the drugs targeted enzyme, Angiotensin

Converting Enzyme (ACE). When food inhibits the drugs adsorption into the body (one of the

effects our design can model), roughly 27% of the drug has any type of impact upon our body.

73% of the drug is wasted {Seem in conflict with the 25% waste}, and simply passes through our

30

body just like anything else that is indigestible. To show this the mass balance can be found in

figure 20.

However, this plays a major role in regulating the blood pressure of the patient, as only 27% of

the drug significantly decreases the apparent affinity of ACE to Angiotensin I. Captopril doesn’t

cease the conversion of Angiotensin I to Angiotensin II (two proteins that regulate our blood

pressure), it simply slows the process down. Angiotensin II is three times more potent in

constricting in our blood vessels then Angitotensin I, which is why this drug is effective (Stewart

et al, 2009.)

Our design is going to be judged a success if we can effectively simulate two steps. One is how

close our design’s mass balance is to a patient’s mass balance in the small intestines. The

second comparison in mass balances is made in the blood stream. When testing begins,

numerous parameters will have to be adjusted. This is a simulation, so we want to create a

scenario that is directly comparable to the human body. These are the parameters adjustments

that are forecasted.

Transmembrane pressure in perforate column membrane

Enzyme concentration in affinity chromatography column

Flow rates of the buffer solution and fluid exiting the stomach vessel

The transmembrane pressure will play a major role in how much of the drug is absorbed

through the perforated column membrane (the small intestines lining). Currently our system

runs on a pump system, and this is will create the pressure to affect the retentate and

permeate ratio.

Immobilizing the enzyme in the column for chromatography will be performed from the

company that the column is purchased from. If the enzyme concentration is not correct to

effectively simulate 60% of the drug interacting with the enzyme, the concentration may have

to be modified. This would be a very expensive modification to make as the cost of the

chromatography column is one of the major costs of this design project.

Economic Analysis

31

The focus of this project was to make a bioreactor that could simulate the adsorption through

the small intestine into the bloodstream and work with drug reactions. By simulating this, it

was hoped that information gathered from the testing would help in further testing on animal

and even humans. By providing the data produced from the design these animals and humans

could be kept safer. There is no real price that can be associated with a human life, but there is

a monetary equivalent to this design.

Building the artificial system is the main cost of the whole design. Giving a generous estimate

to compensate for any unforeseen problems that could arise, Table 4 shows the costs for each

of the major functioning parts and substances added on a per use basis along with an overall

estimate of the whole cost. The costs of the Captopril (Health Warehouse, 2009), the HCl

(Science Kit, 2009), and the Instant Breakfast (Drugstore, 2009) add up to very little compared

to the major costs. The major costs are shown to be the enzyme ACE, the vessel simulating the

stomach, the pumps needed, and the chromatography column. The ACE is very expensive,

because it is very difficult to localize and produce (Bachem, 2009). The Vessel simulating the

stomach is expensive because it contains all instrumentation and control features needed for

the design to work and further features that could be utilized for differing designs depending

on different drugs or enzymes or different experiments (Culotta, 2009). Three pumps will be

needed to keep the flow constant throughout the whole system (Boylan, 2009). The

chromatography column would cost about $8000 since it would need to be custom made for

the project (General Electric Healthcare, 2009). One other cost to account for is the

membrane. If the entire adsorptive surface area of the small intestine was to be accounted for

using this membrane it would cost over 1 million dollars by itself, but since only 1 m2 is being

used then the cost is reduced significantly (Fischer Scientific, 2009).

PROJECT EVALUATION

When 50 to 300 million dollars are spent in a clinical trial per drug, the design of a bioreactor

can be very expensive and still an advantage to the pharmaceutical company doing the drug

testing. That is with the assumption that your design can accurately model the small intestines

32

and stomach of the GI tract, showing how the drug is changed and adsorbed into the body.

Currently all bioreactors being developed for this purpose are still in their research and

development stage.

To establish if this project is a success is establishing a model that will successfully model the

drug chosen. The drug chosen, Captopril, works in the bloodstream. With the current model

we have chosen it successfully establishes all of the parts of the gastrointestinal tract the oral

drug would have to pass in order to get in the blood. This project did establish a relatively low

cost for most of the equipment. In all, this project established what it needed to set up for

future work.

DESIGN SCHEDULE

In designing this artificial stomach and small intestine bioreactor, there have been many

obstacles to overcome and many issues to work through. The original idea for the reactor was

to have a single chamber, representing the stomach with its chemical reactions, that would

account for the intake of all substances, the reactions that would take place, the adsorption and

absorption into the body, and the removal of wastes. With the discovery of enzymatic

reactions occurring in the duodenum and that most adsorption occurs later in the small

intestine the idea of keeping a single chamber reactor was thrown out. Also, with choosing

Captopril, this drug reacts in the bloodstream and this had to be properly represented.

Another issue that that is still troublesome is the fact that there is very little research on the

idea of a stomach/small intestine bioreactor. Lack of information in research made us look at

the basic levels of information on how the stomach and small intestine worked and develop our

own designs based on that.

Timeline