Formative Step-by-Step Task 3

advertisement

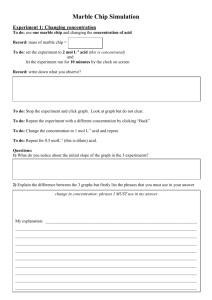

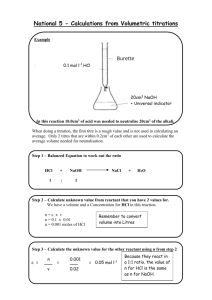

Period 4 & 5 – Task 3 Write up: (1) Title and Purpose (2) Final step by step method that you used. (3) Observations and results (you can use the table to you put together in task 2 if you did it on a separate piece of paper) (4) Graph (you can use the graph you did in task 2 if you did it on a separate piece of paper) (5) Conclusion (6) Discussion (7) Evaluation Kumara Chips and Salt Purpose/Aim: Kumara Chips placed in solution with high concentrations of salt (0.6 mol L-1 and 0.8 mol L-1), will lose mass as the chips will lose water due to osmosis. Kumara chips placed in solution with lower concentrations of salt (distilled water, 0.2 mol L-1 and 0.4 mol L-1) will gain mass as the chips will gain water due to osmosis. Marking (A/M/E): Purpose stating what will happen to the chips in respect to osmosis. Marking (M/E) Method: A method includes: valid (1) Collect distilled water and salt solutions (0.2 molrange L-1; IV - five conc including distilled 0.4 mol L-1, 0.6 mol L-1, 0.8 mol L-1) L-1 (2) Fill three of the plastic containers with 15 water mL ofplus the0.3 0.2mol mol or below and A, above 0.3 L-1 solution. Clearly label each container with 0.2 and B and mol L-1 (step 1); C. – masswater. of chips (3) Repeat with all the other solutions and theDV distilled (stepsize 6) &7 (4) Cut 15 kumara chips from the same kumarabefore using the after (step 10); sized cork borer. Repeats (step 2 & 4) (5) Blot each chip with a paper towel. - volume of (6) Weigh each chip and place each one in eachOV of the plastic solution (step 2), same containers. Record the weight of the chip and the plastic kumara (step 4), same container it has been placed in. (7) Put the lid on each of the plastic container.shape/size chips (step 4), blotting dry before (8) Place all the containers on the same place on the back bench weighing (steps 5 & so they all experience the same changes in temperature. cover to stop (9) Leave all the chips in the solution until next10), period ( 24 hours) evaporation (step 7), (10) Remove each chip, blot it dry with a paper stated towel and reweigh time (step 9), it. Record the final weight against each of the plastic temperature containers. Use the same electronic scalessame to ensure (step 8), same scales consistency. (step 10). Observations: The chips in the distilled water (0.0 mol L-1 salt concentration) looked slightly larger and felt firm. The chips in the 0.8 mol L-1 salt concentration solution were soft and flaccid. Results: Salt Conc Mol L-1 O.0 mol L-1 Plastic Container A B C 0.2 mol L-1 A B C 0.4 mol L-1 A B C 0.6 mol L-1 A B C 0.8 mol L-1 A B C Original mass (g) Final mass (g) Difference in mass (g) % mass change Mean % mass change Mean % change in mass of kumara chips in different salt concentrations Marking (M/E): Sufficient data (valid range, 5 conc’s and repeats) recorded and processed to show trend. 40 Mean % mass change 30 20 10 0 0 0.1 0.2 0.3 0.4 0.5 0.6 -10 -20 -30 Salt concentration (mol L-1) Trend shown by accurate 0.7 0.8 0.9 calculation of % mass change AND by the appropriate graph N.B. line is curved not straight. Conclusion: My results showed that the kumara chips gained mass in distilled water and the low salt concentrations (0.2 mol L-1) and lost mass in the higher concentrations of salt (0.4 mol L-1, 0.6 mol L-1, 0.8 mol L-1). This is almost what I predicted except for the 0.4 mol L-1. This happens because water moves in Marking (A/M/E): Valid conclusion reached and out of the kumara by osmosis. based on the processed data in relation to the purpose of the investigation. Discussion: Marking (M/E): When the chips were put in distilled water they gain mass because the chips gain water from the surrounding solution due uses to osmosis. The process of osmosis causes Discussion a net flow of water, across the semi permeable membrane, along the decreasing knowledge of the water potential gradient from a solution with a highofwaterprocess osmosis to potential to one with a lower water potential. The chips gain or explain the trend water because the distilled water has a higher water potential pattern in the results: than the chips. - gained mass, gained The graph shows that in solutions with a salt concentration less that 0.4 mol L-1 the water potential of thewater, solution inside the due to osmosis cell is still higher than that of the surrounding salt solution semi so (water potential, water moves into the kumara cells by osmosis. In salt membrane, solutions permeable of 0.4 mol L-1 the water potential of the solutions inside and net flow of water, outside the cell are very similar so we would expect very littlewater net flow of water into the kumara cells. potential gradient) As the concentration of the salt solution increases above to in - small mean % 0.4 change 0.8 mol L-1 the potato chip loses more and mass, more mass small because net water the difference in water potential between flow the inside of the kumara cells and the surrounding solution is increasingly loss of mass, water different. This means that when the chips -are placed in the higher concentration solutions more water loss, will move out of the due to osmosis chips as the result of osmosis. Evaluation: My results showed that the chips gained mass in low salt concentrations but lost mass in high concentrations of salt. This conclusion is justified because I use(E): a number of Marking ways to ensure I used the best method possible to make my investigation a fair test. For example I used a cork of close the to borer to make sure all the chips usedEvaluation were cut as investigation by each exactly the same shape as possible. This meant that justification of theof chip had the same surface area available for diffusion conclusionofinthe terms of water across the semi permeable membranes potato cells. The repeats used showed similar results toused, eachsuch the method other. as sufficient data, A change made to my original methodappropriate was to make theof IV, range chips slightly smaller than planned. This was because I had appropriate processing to get all 15 chips from the same kumara could usingso % that mass Ichange, control the variable of water potential in cells in different minimization or removal kumara. of sources of errors, The method was carried out in a way that variables that limitations, could have changed the rate of osmosis, such asbias. evaporation and temperature, were controlled by covering the plastic containers with a lid and keeping them in the same area and conditions for 24 hours.