Process Strategy

W4 4.4

© Ana G. Méndez University System, 2012. All rights reserved.

© Sistema Universitario Ana G. Méndez, 2011. Derechos Reservados.

1

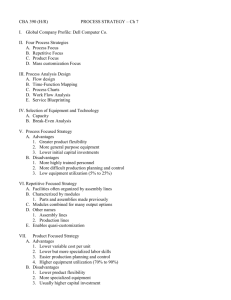

Four Process Strategies

Process Focus

Repetitive Focus

Product Focus

Mass Customization Focus

Process Analysis and Design

Flow Diagrams

Time-Function Mapping

Value-Stream Mapping

Process Charts

Service Blueprinting

Service Process Design

Customer Interaction and Process Design

More Opportunities to Improve

Service Processes

Production Technology

Machine technology

Automatic identification Systems

(AISs)

Process control

Vision system

Robot

Automated storage and retrieval

systems (ASRSs)

Automated guided vehicles (AGVs)

Flexible manufacturing systems

(FMSs)

Computer-integrated

manufacturing (CIM)

Redesign process

2

At the end of the workshop, you will be able to:

1. Describe the four production processes

2. Use the tools of process analysis

3. Describe customer interaction in process design.

4. Identify advances in production technology and

redesign process.

3

High Variety,

one or few

products

Process Focus

projects, job shops

(machine, print,

carpentry)

Variety

Changes in runs

Mass Customization

(difficult to achieve, but

huge rewards)

Repetitive Focus

Product Focus

(commercial baked

goods, steel, glass)

Low Variety,

long runs

only

Low

Volume

Volume

High

Volume

Changes in attributes

4

Four basic strategies

Process focus

Repetitive focus

Product focus

Mass customization

5

Job Shop or Intermittent Process

Many

departments and

many routings

Grinding

Forging

Lathes

Painting

Welding

Drills

Office

Milling

machines

Foundry

6

This is a process flow diagram

for a high quality product and

service in the industry.

Shows the flow of

material or service

7

Assembly Line

Modules

combined

for many

output

options

Raw

materials

and

module

inputs

Few

modules

8

Continuous Work Flow

Few

inputs

Station 1

Station 2

Station 3

Station 4

Output

variations

in size,

shape, and

packaging

9

Repetitive Focus

Flexible people

and equipment

Supportive

supply chains

Effective

scheduling

techniques

Modular techniques

Mass Customization

Rapid

throughput

techniques

Process-Focused

Product-Focused

High variety, low volume

Low utilization (5% to 25%)

General-purpose equipment

Low variety, high volume

High utilization (70% to 90%)

Specialized equipment

10

Flow Diagrams - Show

the movement of

materials

Time-Function Mapping

- Shows flow and time

frame

Value-Stream Mapping Shows flow, time. and

value added beyond the

immediate organization

Process Charts - Use

symbols to show key

activities

Service Blueprinting focuses on

customer/provider

interaction

11

12

Time-Function Mapping

Order

product

Receive

product

Process

order

Wait

Print

Wait

Wait

Wait

Extrude

Move

12 days

13 days

1 day

4 days

1 day 10 days

52 days

Move

1 day

0 day

1 day

13

Value Stream Mapping

14

Process Charts Symbols

15

16

Degree of Customization

High

Low

Mass Service

Degree of Labor

High

Private

banking

Commercial

banking

Full-service

stockbroker

Retailing

Limited-service

stockbroker

Warehouse and

catalog stores

No-frills

airlines

Generalpurpose law firms

Boutiques

Service Factory

Low

Professional Service

Fast-food

restaurants

Airlines

Law clinics

Service Shop

Specialized

hospitals

Fine-dining

restaurants

Hospitals

17

Machine technology

Automatic identification Systems (AISs)

Process control

Vision system

Robot

Automated storage and retrieval systems

(ASRSs)

Automated guided vehicles (AGVs)

Flexible manufacturing systems (FMSs)

Computer-integrated manufacturing (CIM)

18

Increased precision

Increased productivity

Increased flexibility

Improved environmental impact

Reduced changeover time

Decreased size

Reduced power requirements

Improved data acquisition

Reduced data entry errors

Increased speed

Increased scope of process

automation

Bar Codes

RFID

Prepared by María Vázquez

19

Increased process stability

Increased process precision

Real-time provision of

information for process

evaluation

Data available in many forms

Particular aid to inspection

Consistently accurate

Never bored

Modest cost

Superior to individuals

performing the same tasks

Prepared by María Vázquez

20

Perform monotonous or

dangerous tasks

Automated placement and

withdrawal of parts and products

Perform tasks requiring

significant strength or

endurance

Reduced errors and labor

Particularly useful in inventory and

test areas of manufacturing firms

Generally enhanced

consistency and accuracy

Prepared by María Vázquez

21

Computer controls both the workstation and

the material handling equipment

Enhance flexibility and reduced waste

Can economically produce low volume at

high quality

Reduced changeover time and increased

utilization

Stringent communication requirement

between components

Electronically guided and

controlled carts

Used for movement of products

and/or individuals

22

Extension of flexible manufacturing

systems

Backwards to engineering and

inventory control

Forward into warehousing and

shipping

Can also include financial and

customer service areas

Reducing the distinction between lowvolume/high-variety, and highvolume/low-variety production

© Sistema Universitario Ana G. Méndez, 2011. Derechos Reservados.

23

The fundamental rethinking of

business processes to bring

about dramatic improvements in

performance

Relies on reevaluating the

purpose of the process and

questioning both the purpose

and the underlying assumptions

Requires reexamination of the

basic process and its objectives

Focuses on activities that cross

functional lines

Any process is a candidate for

redesign

24

End

After studying the content, please complete

the assigned activities.

© Ana G. Méndez University System, 2012. All rights reserved.

25