POM LECT 10 ver 2

advertisement

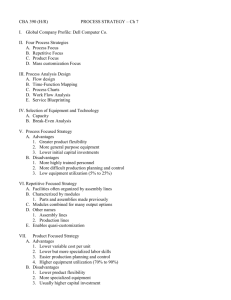

LECTURE 10 LSM733-PRODUCTION OPERATIONS MANAGEMENT By: OSMAN BIN SAIF 1 Summary of Last Session Tools of TQM Check Sheets Scatter Diagrams Cause-and-Effect Diagrams Pareto Charts Flowcharts Histograms Statistical Process Control (SPC) 2 Summary of Last Session (Contd.) The Role of Inspection When and Where to Inspect Source Inspection Service Industry Inspection Inspection of Attributes versus Variables TQM in Services 3 Summary of Last Session (Contd.) Tools for Generating Ideas Check sheets Scatter diagrams Cause-and-effect diagrams Tools to Organize the Data Pareto charts Flowcharts Tools for Identifying Problems Histogram Statistical process control chart 4 Agenda for this session Four Process Strategies Process Focus Repetitive Focus Product Focus Mass Customization Focus Comparison of Process Choices Process Analysis and Design Flow Diagrams Time-Function Mapping Value-Stream Mapping Process Charts Service Blueprinting 5 Agenda for this session (Contd.) Service Process Design Customer Interaction and Process Design More Opportunities to Improve Service Processes Selection of Equipment and Technology Production Technology Machine Technology Automatic Identification Systems (AISs) and RFID Process Control Vision Systems Robots 6 Agenda for this session (Contd.) Production Technology (cont.) Automated Storage and Retrieval Systems (ASRSs) Automated Guided Vehicles (AGVs) Flexible Manufacturing Systems (FMSs) Computer-Integrated Manufacturing (CIM) Technology in Services Process Redesign Ethics and Environmentally Friendly Processes 7 Comparison of Processes Process Focus Repetitive Focus Product Focus Mass Customization (Low volume, high variety) (Modular) (High-volume, low-variety) Small quantity, large variety of products Long runs, standardized product made from modules Large quantity, small variety of products Large quantity, large variety of products General purpose equipment Special equipment aids in use of assembly line Special purpose equipment Rapid changeover on flexible equipment (High-volume, high-variety) Table 7.2 8 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Operators are broadly skilled Employees are modestly trained Operators are less broadly skilled Flexible operators are trained for the necessary customization Many job instructions as each job changes Repetition reduces training and changes in job instructions Few work orders and job instructions because jobs standardized Custom orders require many job instructions Table 7.2 9 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Raw material inventories high JIT procurement techniques used Raw material inventories are low Raw material inventories are low Work-inprocess is high JIT inventory techniques used Work-inprocess inventory is low Work-inprocess inventory driven down by JIT, lean production Table 7.2 10 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Units move slowly through the plant Movement is measured in hours and days Swift movement of unit through the facility is typical Goods move swiftly through the facility Finished goods made to order Finished goods made to frequent forecast Finished goods made to forecast and stored Finished goods often build-to-order (BTO) Table 7.2 11 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Scheduling is complex, trade-offs between inventory, availability, customer service Scheduling based on building various models from a variety of modules to forecasts Product Focus (High-volume, low-variety) Relatively simple scheduling, establishing output rate to meet forecasts Mass Customization (High-volume, high-variety) Sophisticated scheduling required to accommodate custom orders Table 7.2 12 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Fixed costs low, variable costs high Fixed costs dependent on flexibility of the facility Fixed costs high, variable costs low Fixed costs high, variable costs must be low Costing estimated before job, known only after the job Costs usually known due to extensive experience High fixed costs mean costs dependent on utilization of capacity High fixed costs and dynamic variable costs make costing a challenge Table 7.2 13 Crossover Charts Variable costs Variable costs $ Variable costs $ $ Fixed costs Fixed costs Fixed costs Repetitive Process B Low volume, high variety Process A High volume, low variety Process C $ 400,000 300,000 200,000 Fixed cost Process A Figure 7.6 (2,857) V1 V2 (6,666) Fixed cost Process B Fixed cost Process C Volume 14 Focused Processes Focus brings efficiency Focus on depth of product line rather than breadth Focus can be Customers Products Service Technology 15 Changing Processes Difficult and expensive May mean starting over Process strategy determines transformation strategy for an extended period Important to get it right 16 Process Analysis and Design Flow Diagrams - Shows the movement of materials Time-Function Mapping - Shows flows and time frame Value-Stream Mapping - Shows flows and time and value added beyond the immediate organization Process Charts - Uses symbols to show key activities Service Blueprinting - focuses on customer/provider interaction 17 “Baseline” Time-Function Map Customer Order product Sales Process order Production control Receive product Wait Plant A Print Warehouse Wait Wait Extrude Plant B Move Transport Figure 7.7 Wait 12 days 13 days 1 day 4 days 1 day 52 days Move 10 days 1 day 0 day 1 day 18 “Target” Time-Function Map Customer Order product Sales Process order Production control Receive product Wait Plant Print Extrude Warehouse Wait Transport Move 1 day 2 days 1 day 1 day 1 day 6 days Figure 7.7 19 Value-Stream Mapping Figure207.8 Process Chart Figure 7.9 Service Blueprint Focuses on the customer and provider interaction Defines three levels of interaction Each level has different management issues Identifies potential failure points 22 Service Blueprint Personal Greeting Level #1 Service Diagnosis Perform Service Customer arrives for service Customer departs F Warm greeting and obtain service request Determine specifics No Standard request Level #2 Direct customer to waiting room F Level #3 Friendly Close Can service be done and does customer approve? F F Yes Yes Notify customer and recommend an alternative provider Customer pays bill F F No Notify customer the car is ready Perform required work F Prepare invoice Figure 7.10 F 23 Process Analysis Tools Flowcharts provide a view of the big picture Time-function mapping adds rigor and a time element Value-stream analysis extends to customers and suppliers Process charts show detail Service blueprint focuses on customer interaction Service Process Matrix Degree of Customization High Low Mass Service Professional Service Private banking Degree of Labor High Commercial banking Full-service stockbroker Generalpurpose law firms Boutiques Retailing Service Factory Law clinics Limited-service stockbroker Low Warehouse and catalog stores Fast-food restaurants Service Shop Specialized hospitals Fine-dining restaurants Hospitals Airlines Figure 7.11 No-frills airlines 25 Service Process Matrix Mass Service and Professional Service Labor involvement is high Selection and training highly important Focus on human resources Personalized services Service Factory and Service Shop Automation of standardized services Low labor intensity responds well to process technology and scheduling Tight control required to maintain standards 26 Improving Service Productivity Strategy Technique Example Separation Structure service so customers must go where service is offered Bank customers go to a manager to open a new account, to loan officers for loans, and to tellers for deposits Self-service Self-service so customers examine, compare, and evaluate at their own pace Supermarkets and department stores, Internet ordering Table 7.3 27 Improving Service Productivity Strategy Technique Example Postponement Customizing at delivery Customizing vans at delivery rather than at production Focus Restricting the offerings Limited-menu restaurant Modules Modular selection of service, modular production Investment and insurance selection, prepackaged food modules in restaurants Table 7.3 28 Improving Service Productivity Strategy Technique Example Automation Separating services that may lend themselves to automation Automatic teller machines Scheduling Precise personnel scheduling Scheduling ticket counter personnel at 15-minute intervals at airlines Training Clarifying the service options, explaining how to avoid problems Investment counselor, funeral directors, aftersale maintenance personnel Table 7.3 29 Improving Service Processes Layout Product exposure, customer education, product enhancement Human Resources Recruiting and training Impact of flexibility 30 Equipment and Technology Often complex decisions Possible competitive advantage Flexibility Stable processes May allow enlarging the scope of the processes 31 Production Technology Machine technology Automatic identification systems (AISs) Process control Vision system Robot Automated storage and retrieval systems (ASRSs) Automated guided vehicles (AGVs) Flexible manufacturing systems (FMSs) Computer-integrated manufacturing (CIM) 32 Machine Technology Increased precision Increased productivity Increased flexibility Improved environmental impact Reduced changeover time Decreased size Reduced power requirements 33 Automatic Identification Systems (AISs) Improved data acquisition Reduced data entry errors Increased speed Increased scope of process automation Example – Bar codes and RFID 34 Process Control Increased process stability Increased process precision Real-time provision of information for process evaluation Data available in many forms 35 Process Control Software 36 Vision Systems Particular aid to inspection Consistently accurate Never bored Modest cost Superior to individuals performing the same tasks 37 Robots Perform monotonous or dangerous tasks Perform tasks requiring significant strength or endurance Generally enhanced consistency and accuracy 38 Automated Storage and Retrieval Systems (ASRSs) Automated placement and withdrawal of parts and products Reduced errors and labor Particularly useful in inventory and test areas of manufacturing firms 39 Automated Guided Vehicle (AGVs) Electronically guided and controlled carts Used for movement of products and/or individuals 40 Flexible Manufacturing Systems (FMSs) Computer controls both the workstation and the material handling equipment Enhance flexibility and reduced waste Can economically produce low volume at high quality Reduced changeover time and increased utilization Stringent communication requirement between components 41 Computer-Integrated Manufacturing (CIM) Extension of flexible manufacturing systems Backwards to engineering and inventory control Forward into warehousing and shipping Can also include financial and customer service areas Reducing the distinction between lowvolume/high-variety, and high-volume/lowvariety production 42 ComputerIntegrated Manufacturing (CIM) Figure 7.12 43 Technology in Services Service Industry Example Financial Services Debit cards, electronic funds transfer, ATMs, Internet stock trading Education Electronic bulletin boards, on-line journals, WebCT and Blackboard Utilities and government Automated one-man garbage trucks, optical mail and bomb scanners, flood warning systems Restaurants and foods Wireless orders from waiters to kitchen, robot butchering, transponders on cars that track sales at drive-throughs Communications Electronic publishing, interactive TV Table 7.4 44 Technology in Services Service Industry Example Hotels Electronic check-in/check-out, electronic key/lock system Wholesale/retail trade ATM-like kiosks, point-of-sale (POS) terminals, e-commerce, electronic communication between store and supplier, bar coded data Transportation Automatic toll booths, satellite-directed navigation systems Health care Online patient-monitoring, online medical information systems, robotic surgery Airlines Ticketless travel, scheduling, Internet purchases Table 7.4 45 Process Redesign The fundamental rethinking of business processes to bring about dramatic improvements in performance Relies on reevaluating the purpose of the process and questioning both the purpose and the underlying assumptions Requires reexamination of the basic process and its objectives Focuses on activities that cross functional lines Any process is a candidate for redesign 46 Ethics and Environmentally Friendly Processes Reduce the negative impact on the environment Encourage recycling Efficient use of resources Reduction of waste by-products Use less harmful ingredients Use less energy 47 Summary of this session Four Process Strategies Process Focus Repetitive Focus Product Focus Mass Customization Focus Comparison of Process Choices Process Analysis and Design Flow Diagrams Time-Function Mapping Value-Stream Mapping Process Charts Service Blueprinting 48 Summary of this session (Contd.) Service Process Design Customer Interaction and Process Design More Opportunities to Improve Service Processes Selection of Equipment and Technology Production Technology Machine Technology Automatic Identification Systems (AISs) and RFID Process Control Vision Systems Robots 49 Summary of this session (Contd.) Production Technology (cont.) Automated Storage and Retrieval Systems (ASRSs) Automated Guided Vehicles (AGVs) Flexible Manufacturing Systems (FMSs) Computer-Integrated Manufacturing (CIM) Technology in Services Process Redesign Ethics and Environmentally Friendly Processes 50 THANK YOU 51