MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations

advertisement

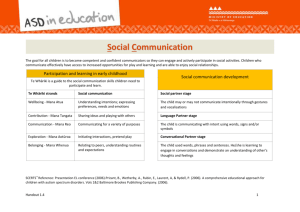

MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management Topic: Process Strategy Slide 1 Welcome, this is workshop four, the Process Strategy. Slide 2 Four Process Strategies Process Focus Repetitive Focus Product Focus Mass Customization Focus Process Analysis and Design Flow Diagrams Time-Function Mapping Value-Stream Mapping Process Charts Service Blueprinting Service Process Design Customer Interaction and Process Design More Opportunities to Improve Service Processes Production Technology Machine technology Automatic identification Systems (AISs) Process control Vision system Robot Automated storage and retrieval systems (ASRSs) Automated guided vehicles (AGVs) Flexible manufacturing systems (FMSs) Computer-integrated manufacturing (CIM) Redesign process Slide 3 At the end of the workshop you will be able to: MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 1 MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management 1. Describe the four production processes. 2. Define and analyze process design tools. 3. Describe customer interaction in process design. 4. Identify advances in production technology and redesign process. Slide 4 The four basic strategies, volume, and variety production processes. 1. Process Focus is low-volume, high variety products in some organizations called job shops. In a factory, these processes might be departments like welding, grinding, and painting. In an office the processes might be accounts payable, sales and payroll. In a restaurant, they might be bar, grill, and bakery. 2. Repetitive Focus falls between product and process focus. Repetitive focus uses modules that are parts or components previously prepared, often in a continuous process. This is a classic example of an assembly line. They are used in building products such as automobiles and household appliances. This type of production allows more customizing than a continuous process; modules are assembled to get a quasi-custom product. 3. Product Focus is a high volume, low variety process. The facilities are organized around products. They are also called continuous process because they have very long, continuous production runs such as light bulbs and rolls of paper. The specialized nature of the facility requires high fixed cost, but low variable costs. The reward is high facility utilization. 4. Mass customization is the rapid, low cost production of goods and services that fulfill increasingly unique customer desires. But mass customization is not just about variety; it is about making precisely what the customer wants when the customer wants it economically. Traditionally, it is low volume manufacturing (a process focus) at the cost of standardized high-volume (product-focused) production. However, achieving mass customization is a challenge that requires sophisticated operational capabilities. Slide 5 Within these basic strategies there are many ways they may be implemented. MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 2 MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management Slide 6 Process Focus are low-volume, high variety products that in some organizations are called job shops. In a factory, these processes might be departments like welding, grinding, and painting. In an office the processes might be accounts payable, sales, and payroll. In a restaurant, they might be bar, grill, and bakery. Process focus may also be called intermittent process. These facilities have high variable costs with extremely low utilization of facilities. These types of facilities can be hospitals, machine shops, and restaurants. Slide 7 This is a process flow diagram that shows the flow of materials, services, or information with the typical arrows. Slide 8 Repetitive focus falls between the product and process focus. The repetitive process is a product-oriented production process that uses modules. Modules are parts or components of a product previously manufactured or prepared, often in a continuous process, assembly line or production line. Fast-food firms are an example of repetitive process using modules. Repetitive process is more structured and enables quasi-customization. Slide 9 Product Focus is a high volume, low variety process. Facilities are organized taking the product into consideration. Continuous improvement of production runs enables process efficiency. Each station varies depending on the size, shape, or how the product is packaged for that station. Examples of product focus can be baked products, steel, glass, light bulbs, or rolls of paper. Typically, facilities require high fixed cost, low variable costs for high facility utilization and generally less skilled labor. Slide 10 Mass customization focus implies rapid, low-cost production that conforms to unique customer desires. This process is the most complex of the four processes and requires management to use the facilities to accommodate the customer’s needs. It is a combination of the flexibility of a process focus with the efficiency of a MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 3 MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management product focus. The achievement of mass customization is a challenge because it requires sophisticated operational capabilities. Slide 11 Flow Diagrams - Show the movement of materials Time-Function Mapping - Shows flow and time frame Value-Stream Mapping - Shows flow, time, and value added beyond the immediate organization Process Charts - Use symbols to show key activities Service Blueprinting - focuses on customer/provider interaction Slide 12 Flow Diagrams are a schematic or drawing of the movement of material, products, or people. This is a an example of a flow of operations for a factory from the market needs and demand, all the way to providing the product to the consumer and accounts for the cost of the product. Slide 13 Time-Function Mapping is a process in a flow diagram, with time added on the horizontal axis. This tool is also called process mapping. The nodes indicate the activities and the arrows indicate the flow direction, with time on the horizontal axis. This type of analysis allows users to identify and eliminate waste such as extra steps, duplication, and delay. Slide 14 Value-Stream Mapping (VSM) is a variation of time-function mapping; however, value-stream mapping takes an expanded look at where value is added (and not added) in the entire production process, including the supply chain. The idea is to start with the customer and understand the production process, but value-stream mapping extends the analysis back to suppliers. Slide 15 Process Charts use symbols, time, and distance to provide an objective and structured way to analyze and record the activities that make up a process. These charts allow focusing on value-added activities. MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 4 MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management Slide 16 Service Blueprinting is a tool used in manufacturing products with high service content. This process focuses on the costumer and the provider’s interaction with the consumer. Slide 17 Service process design, by its nature, implies that some interaction and customization is needed. The more the manager designs the process to accommodate special requirements, the more effective and efficient the process will be. Customer interaction and process design will depend on the type of service organization. Service processes provide more opportunities for improvement. Layout design is an integral part in many service processes, particularly in retailing, dining, and banking. Since layout design is such an integral part of many services, it provides continuing opportunity for increasing orders. Human Recourses is important particularly because of the recruiting issue and training. This can have a tremendous impact on the overall process performance. Slide 18 The nine areas of importance in Production Technology are: 1. Machine technology 2. Automatic identification systems 3. Process control 4. Vision systems 5. Robots 6. Automated storage and retrieval systems 7. Automated guided vehicles 8. Flexible manufacturing systems 9. Computer integrated manufacturing Slide 19 Machine Technology Increased precision Increased productivity Increased flexibility Improved environmental impact MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 5 MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management Reduced changeover time Decreased size Reduced power requirements Automatic Identification Systems (AIS) Improved data acquisition Reduced data entry errors Increased scope of process automation Radio Frequency Identification (RFID) is a wireless system in which integrated circuits with antennas send radio waves. Slide 20 Process Control is the use of information technology to control a physical process. Increased process stability Increased process precision Real-time provision of information for process evaluation Data is available in many forms Vision systems combine video cameras and computer technology and are often used as inspection tools. Consistently accurate Never bored Modest cost Superior to individuals performing the same tasks Slide 21 Robot: a flexible machine with the ability to hold, move, or grab items. It functions through electronic impulses that activate motors and switches. Perform monotonous or dangerous tasks Perform tasks requiring significant strength or endurance Generally enhanced consistency and accuracy Automated Storage and Retrieval System (ASRS), a computer controlled warehouse that provides for the automatic placement of parts into and from designated places within a warehouse. MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 6 MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management Slide 22 Automated Guided Vehicles (AGV), electronically guided and controlled vehicles used to move material Electronically guided and controlled vehicles Used for movement of products and/or individuals Flexible Manufacturing System (FMS): a system that uses an automated work cell controlled by electronic signals from a common centralized computer facility. Computer controls both the workstation and the material handling equipment Enhances flexibility and reduced waste Can economically produce low volume with high quality Reduced changeover time and increased utilization Stringent communication requirement between components Slide 23 Computer-integrated Manufacturing (CIM) Extension of flexible manufacturing systems Backwards to engineering and inventory control Forward into warehousing and shipping Can also include financial and customer service areas Reducing the distinction between low-volume/high-variety, and high-volume/lowvariety production Slide 24 Process Redesign is the fundamental rethinking of business processes to bring about dramatic improvements in performance. The fundamental rethinking of business processes to bring about dramatic improvements in performance Relies on reevaluating the purpose of the process and questioning both the purpose and the underlying assumptions Requires reexamination of the basic process and its objectives Focuses on activities that cross functional lines Any process is a candidate for redesign MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 7 MANA 705 DL - WORKSHOP 4 W4_4_4_Narrative Operations Management Slide 25 After studying the content, please complete the assigned activities. MANA 705 DL © Sistema Universitario Ana G. Méndez, 2012. Derechos Reservados. 8