Department of Physics, Brigham Young University

1

Supporting Information for:

2

3

4

Effects of Catalyst Thickness on the Fabrication and Performance of Carbon

Nanotube-Templated Thin Layer Chromatography Plates

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Supriya S. Kanyal

Department of Chemistry and Biochemistry, Brigham Young University, Provo, Utah 84602

David S. Jensen, Andrew J. Miles, Andrew E.

Dadson, Michael A. Vail

Diamond Analytics, Orem, Utah 84058

Rebecca Olsen

Department of Chemistry and Biochemistry, Brigham Young University, Provo, Utah 84602

Fabien Scorza, Judy Nichols

CAMAG Scientific Inc., Wilmington, N.C. 28401

Richard R. Vanfleet, Robert C. Davis

Department of Physics, Brigham Young University, Provo, Utah 84602

19

20

21

Matthew R. Linford (a)

22

Department of Chemistry and Biochemistry, Brigham Young University, Provo, Utah 84602

(a) Electronic mail and correspondence: mrlinford@chem.byu.edu

23

1

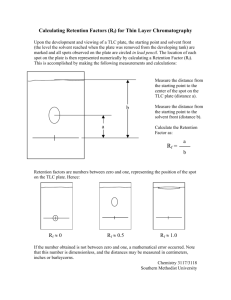

24 FTIR Analysis:

25 Fourier transform infrared spectroscopy of silica helps determines the nature of the material and

26

27 its silanol groups. Spectra were collected in Kubelka-Munk units with a focus on the peak around

3740 cm

-1

. A peak position below this threshold signifies vicinal silanol groups which is

28 desirable for chromatography. Higher wavenumbers are attributed to more acidic, islolated

29 silanol groups that can cause tailing. Supporting Information, Figure 1 shows the FTIR spectra of

30 some of the materials analyzed in our study. The isolated silanol peaks appear at 3736.8, 3738.49

31 and 3742.3 cm

-1

for the Analtech, Merck, and our TLC plate material, repectively.

32

33 Supporting Information Figure 1. FTIR spectra of silica samples (preheated at 120 °C for 24 h).

34 (a) Black line: material from an Analtech TLC plate. (b) Red line: material from a Merck

35 HPTLC plate. (c) Green line: material from our microfabricated TLC plate .

36

2

37

38 Supporting Information Figure 2. Separations of three analgesics on microfabricated TLC plates

39 using mobile phase compositions of (a) 4:1 toluene:acetonitrile (v/v) without TEA

40 (triethylamine), (b) 4:1 toluene:acetonitrile (v/v) with 1.0% (v/v) TEA, (c) 6:1

41 toluene:acetonitrile (v/v) without TEA, and (d) 4:1 toluene:acetonitrile (v/v) without TEA (using

42 a TLC plate with wider channels than the other plates).

3

43

44 Supporting Information Figure 3. Histograms showing distributions of Fe nanoparticles for initial

45 Fe thicknesses of (a) 6 nm, (b) 8 nm, (c) 12 nm and (d) 18 nm.

4