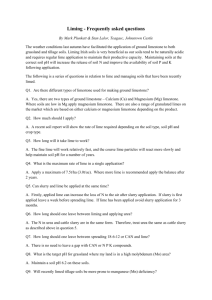

Implementing a successful clubroot liming program

advertisement

Clubroot management strategies for brassica production Aaron Heinrich and Alex Stone Dept. of Horticulture It’s called clubroot for a reason… Hosts And more… Susceptibility varies by species and cultivar Clubroot’s impact “In the past 3 years [2009-12] we have had a 25% loss in our brassica crops due to clubroot, costing us between $60-80K/year. We are running out of clubroot free ground on which to rotate brassica crops.” “In 2013 we experienced a 30 to 50% loss in 5 of our highest yielding brassica crops this year totaling $20K. Three years ago we played out this scenario knowing that our future looked quite bleak... We need to figure out a way to grow brassicas in fields that have a high clubroot population.” Is incidence increasing? 1. Increase in radish and turnip cover crop seed 2. More farms with 15+ year history of short rotations (<4 yrs) 3. Increased brassica production to meet demand 4. More overwintering brassica crops Disease cycle Disease severity affected by: 1. Moisture 2. Temperature 3. Low soil pH 4. Spore density Management strategies Control not eradication is the goal 1. Rotation – 5 to 7 years out of brassicas 2. Sanitation 3. pH manipulation – 4. 5. 6. 7. lime to pH ≥7.0 Boron? Biologic controls? Resistant cultivars? Water management Management strategies Control not eradication is the goal 1. Rotation – 5 to 7 years out of brassicas 2. Sanitation 3. pH manipulation – 4. 5. 6. 7. lime to pH ≥7.0 Boron? Biologic controls? Resistant cultivars? Water management Liming success in California • 1978 clubroot first identified • Started aggressive liming program • Still present but controlled 2012 clubroot survey Response from 19 of 37 farmers • 83% had used lime as a control – 21% aimed for pH ≥6.8 – 52% verified if target pH reached – 26% said liming helped Is liming effective in western Oregon? Are farmers liming “correctly”? 2014 Greenhouse study: Cauliflower Control pH= 5.7 Infection rate: 100% Avg plant wt: 0.3 g Limed pH ≥ 7.1 Infection rate: <4% Avg plant wt: 0.8 g 2014 Greenhouse studies: cauliflower Infection rate and severity (%) 100 80 5 rating Dead/ 60 4 rating dying 3 rating 40 2 rating 20 Minor clubs 1 rating on laterals 0 Control pH 5.7 1. 2. 3. 4. Serenade Boron (10 lb/A) Lime Lime 5.7 5.7 6.3 7.1 Serenade not effective Boron reduced severity but not infection rate Increasing pH from 5.7 to 6.3 slightly effective pH >7.0 highly effective 2014 Field studies: broccoli & kale 2014 Field studies pH 6.7 pH 7.3 2014 Field studies: Lacinato Kale 450 90 400 Rating 3 >50% clubbed Rating 2 <50% clubbed Rating 1 on laterals clubs 80 70 60 50 40 30 20 Plant wt (g) Infection rate and severity (%) 100 350 300 250 200 150 100 10 50 0 No lime pH 6.7 Lime 0 No lime lime 7.3 In 3 field trials: • 44-77% reduction in infection rate • 74-90% reduction in disease severity • Serenade and B (4 and 8 lb/A) not effective in these studies Why is there a difference between greenhouse and field studies? Clubroot field trial: western WA Treatment Control Limed (field mixed) Limed (sieved/mixed) pH 6.0 7.0 7.0 Infected plants (%) 91 34 Same pH, 6 different infection rate (Adapted from Dobson et al., 1983) Importance of uniform soil mixing Clubroot greenhouse trial Treatment Control Limed (field mixed) Limed (sieved/mixed) Microscale Infected pH variability pH plants (%) (pH unit) 5.9 100 0.7 6.4 86 1.1 6.5 25 0.3 Under field conditions, 100% clubroot control highly unlikely with liming. (Adapted from Dobson et al, 1983) Implementing a successful clubroot liming program Target pH ≥ 7.0 Steps: 1. 2. 3. 4. 5. Estimate lime requirement Choose lime material Apply at correct time Incorporate thoroughly Measure soil pH Step 1: Estimate lime requirement 1. Use SMP buffer test and OSU pub. EM 9057 to raise pH to ~6.7 (6” incorporation depth) 2. Multiply SMP buffer rate by 1.5-2.0 to increase pH >6.7 7.5 7.3 7.1 6.9 6.7 6.5 6.3 6.1 5.9 SMP Buffer 1.5-2.0 x SMP Buffer 0 2 4 ton lime/acre 6 Step 2: Choose lime material Product Most reactive Least reactive Form Cost material only ($/ton) Microna Ag-H2O Powder 210 Microna Access Powder 105 Ash Grove Ag lime Powder 60 CalPril Prilled 260 Microna Garden Pearls Prilled 392 Most economical, similar performance Using pelleted lime Advantages – Easy to handle Disadvantages – Expensive – Less reactive (i.e. requires higher rates) – Requires additional steps Using pelleted lime efficiently If incorporated too soon, the pellets will not disperse! Option 1: – Broadcast – Apply irrigation (or wait for rain) – Till Option 2: – – – – Broadcast 1st tillage If sufficient moisture, no irrigation needed 2nd tillage 1.5 minutes Step 3: Apply at correct time Apply 1 wk minimum before planting 7.2 7.0 pH 6.8 6.6 6.4 Ash Grove (3 t/a) 6.2 Microna Ag H2O (3.1 t/a) 6.0 Microna Access (3.0 t/a) 5.8 Garden Pearls (3.6 t/a) Cal Pril (3.3 t/a) 5.6 0 1 2 3 Weeks after application 4 Step 4: Incorporate thoroughly Clubroot greenhouse trial Treatment Control Limed (field mixed) Limed (sieved/mixed) Microscale Infected pH variability pH plants (%) (pH unit) 5.9 100 0.7 6.4 86 1.1 6.5 25 0.3 (Adapted from Dobson et al., 1983) Step 5: Measure soil pH Soil sample! • Verify if target pH reached Caution: if you can see unreacted lime, the soil test pH may be higher than what the plants are experiencing! Integrated Clubroot Management • • • • • Scouting Rotation (4-5+ yrs) Maintain soil pH ≥6.8 Plant resistant varieties Irrigation management No one strategy is enough! Acknowledgements We thank our farmer partners for their collaboration as well as the following organizations for funding this project: The Agriculture Research Foundation Oregon Processed Vegetable Commission