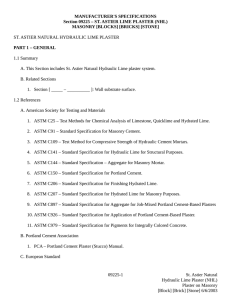

Whole Doc

advertisement

APPENDIX A SPECIFICATION SPECIFICATION Plaster: Generally new internal plastering to masonry walls and repairs to existing plaster on masonry shall be in three coat work to the following specification: Scratch Coat: 1 part non-hydraulic mature lime putty (thick consistency) to 3 parts, sharp, well graded sand, with the addition of 2kg of horse or goat hair per tonne of plaster. Floating Coat: 1 part non-hydraulic mature lime putty (thick consistency) to 3 parts, sharp, well graded sand, with the addition of 2kg of finer goat hair per tonne of plaster. Setting Coat: 1 part non-hydraulic mature lime putty (thick consistency) to 1 or 2 parts kiln dried, sieved silver sand, depending on the finish required. Limewash: 1 part non-hydraulic mature lime putty added to 3 parts clean water, in a plastic dustbin with a lid, and thoroughly mixed with a plasterer’s whisk attachment on an electric drill. The limewash should be the consistency of semi-skimmed milk and when a clean steel trowel is dipped into the mix it should form a definite line across the trowel but should still be translucent against the grey steel. Colour with natural earth pigments. Re-pointing Mortar: 1 part NHL 3.5 lime to 3 parts, sharp, well graded sand, coloured with natural earth pigments, to suit the stone colour. Limecrete Floors: Compacted and levelled clay subsoil (blinded with sand to level, if necessary); breather membrane (vapour permeable geotextile); 20-10mm Coated fired clay aggregate; breather membrane (vapour permeable geotextile); 150mm limecrete (1 part NHL 5 lime to 3 parts uncoated lightweight fired clay aggregate balls in a size of 0 – 20mm, mix to a porridgey consistency); 65mm lime screed (1 part NHL 5 lime to 3 parts, sharp, well graded sand), screed to be increased in thickness as necessary in areas where underfloor heating is to be installed.