TSDSI-M2M-TR-UCD_Utilities-V0.1.0

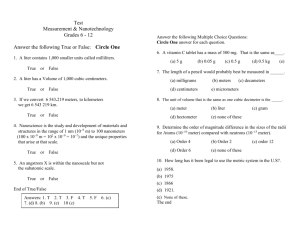

advertisement