March 20, 2014 Denver Regional Educator Micro Summit

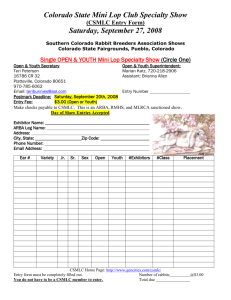

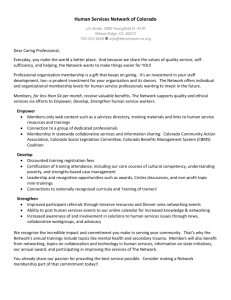

advertisement