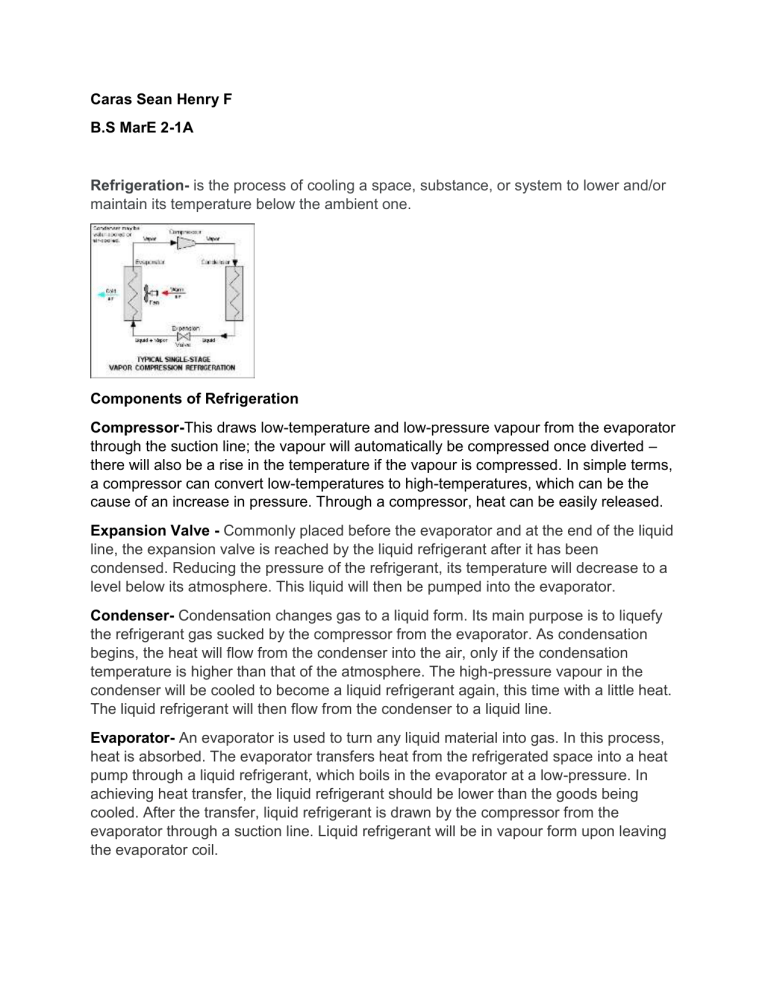

Caras Sean Henry F B.S MarE 2-1A Refrigeration- is the process of cooling a space, substance, or system to lower and/or maintain its temperature below the ambient one. Components of Refrigeration Compressor-This draws low-temperature and low-pressure vapour from the evaporator through the suction line; the vapour will automatically be compressed once diverted – there will also be a rise in the temperature if the vapour is compressed. In simple terms, a compressor can convert low-temperatures to high-temperatures, which can be the cause of an increase in pressure. Through a compressor, heat can be easily released. Expansion Valve - Commonly placed before the evaporator and at the end of the liquid line, the expansion valve is reached by the liquid refrigerant after it has been condensed. Reducing the pressure of the refrigerant, its temperature will decrease to a level below its atmosphere. This liquid will then be pumped into the evaporator. Condenser- Condensation changes gas to a liquid form. Its main purpose is to liquefy the refrigerant gas sucked by the compressor from the evaporator. As condensation begins, the heat will flow from the condenser into the air, only if the condensation temperature is higher than that of the atmosphere. The high-pressure vapour in the condenser will be cooled to become a liquid refrigerant again, this time with a little heat. The liquid refrigerant will then flow from the condenser to a liquid line. Evaporator- An evaporator is used to turn any liquid material into gas. In this process, heat is absorbed. The evaporator transfers heat from the refrigerated space into a heat pump through a liquid refrigerant, which boils in the evaporator at a low-pressure. In achieving heat transfer, the liquid refrigerant should be lower than the goods being cooled. After the transfer, liquid refrigerant is drawn by the compressor from the evaporator through a suction line. Liquid refrigerant will be in vapour form upon leaving the evaporator coil. Steering Gear-A Steering Gear is the equipment provided on ships to turn the ship to left (Port side) or to right (Starboard side) while in motion during sailing.The Steering Gear works only when the ship is in motion and, does not work when the ship is stationary. Physical and Chemical Properties of Fuel Oil density, viscosity, flash point, and adhesion. fuel oils consist of about 85 to 90% of carbon, 13 to 8% of hydrogen and a small percentage of Sulphur, oxygen and nitrogen Physical and Chemical Properties of Lubricating Oil A high boiling point and low freezing point (in order to stay liquid within a wide range of temperature) A high viscosity index Thermal stability Hydraulic stability Demulsibility Corrosion prevention A high resistance to oxidation Hydrocarbons: Hydrocarbons (organic compounds composed exclusively of carbon and hydrogen) predominate in all crude oils and can be further subdivided into the following: – Alkanes, known as paraffins, with saturated linear or branched-chain structures, – Alkenes, known as olefins, unsaturated molecules, but comparatively rare in crude – Alicyclics, known as naphthenes, are saturated cyclic structures based on five and Six-membered – Aromatics, cyclic structures with conjugated double bonds, mainly based on the six-membered benzene ring.