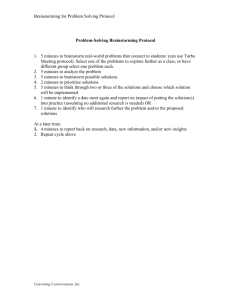

Document

advertisement

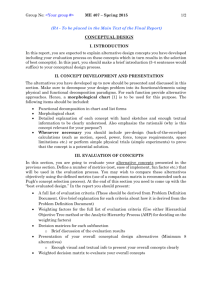

% of product cost committed IMPORTANCE OF PROPER PROBLEM DEFINITION 100 80 60 40 20 0 Specification Development Conceptual Design Detailed design Time After specifications phase, we have already committed ~40% of product cost! 1 CONCEPTUAL DESIGN PHASE 1. Specification Development / Planning Phase Gantt charts CPM Customer surveys Customer interviews QFD Determine need, customer and engineering requirements Develop a project plan 2. Conceptual Design Phase Generate and evaluate concepts Select best solution 3. Detail Design Phase Documentation and part specification Prototype evaluation 4. Production Phase Component manufacture and assembly Plant facilities / capabilities 5. Service Phase Installation, use , maintenance and safety 6. Product Retirement Phase Length of use, disposal, and recycle 2 CONCEPT GENERATION Concept - is an idea that can be represented in a rough sketch or with notes of what might someday be a product. 3 CONCEPT GENERATION If you generate one idea it will probably be a poor idea if you generate twenty ideas then you might have one good idea 4 CONCEPT GENERATION So how do we generate those concepts? Basic philosophy for generating concepts: Form follows function Creativity must be controlled by engineering judgment / expertise / experience 5 CONCEPT GENERATION AND SELECTION SUMMARY Feasibility judgment Functional Decomposition QFD Technology readiness Go/no go screening Morphological Analysis Decision matrix method Concept 1 Need Required functionality Concept 2 Final concept Concept 3 … Concept n Ideation Brainstorming Patents Reference (Books, Trade Journals) Experts’ help 6 SOURCES FOR CONCEPT IDEAS 1. Ideation 2. Brainstorming - a group oriented technique 3. Patents - extensive patent search may be required. (Note: there are over 5 million patents in the U.S.) 4. Reference books and trade journals - most reference books give analytical techniques and few design ideas (Trade journals are a good source, but generally are targeted at specific disciplines). 5. Experts to help generate concepts - a good source of information are manufacturers catelogues (check the Thomas Registry). 6. Functional decomposition and morphological analysis 7 IDEATION 1. Get a general idea of the design problem and develop different ways to tackle it Do not worry about practicality Do not refine ideas 2. Find feasible ideas If only some elements of an idea work, extract them for inclusion in the next iteration 3. Pick, choose and recombine ideas Using useful elements from all ideas 4. Refine List three concepts and add elements you really need in the finished product 8 BRAINSTORMING Fundamental Principles of Brainstorming 1. Criticism is not allowed - any attempt to analyze, rejecty, or evaluate ideas is postponed until after the brainstorming session. 2. All ideas brought forth should be picked up by the other people - participants should seek ways of improving the ideas of others. 3. Participants should divulge all ideas that enter their mind - the wilder the idea, the better. 4. Provide as many ideas as possible within a relatively short time - the greater the number of ideas, the more likelihood of useful results. 9 BRAINSTORMING Brainstorming is an organized approach for producing creative ideas by letting the mind think without interruption. Brainstorming can be done either individually or in a group; in group brainstorming sessions, the participants are encouraged, and often expected, to share their ideas with one another as soon as they are generated. The key to brainstorming is not to interrupt the thought process. As ideas come to the mind, they are captured and stimulate the development of better ideas. An essential element of brainstorming is putting criticism 'on hold'. Instead of immediately stating what might be wrong with an idea, the participants focus on extending or adding to it, reserving criticism for a later 'critical stage' of the process. By suspending judgment, you create a supportive atmosphere where participants feel free to generate unusual ideas. 10 BRAINSTORMING Procedure for a typical brainstorming session A meeting room is equipped with a flipchart, blackboard, or overhead projector placed in a prominent location. Between six and twenty people with an interest in the subject (although not necessarily experts) are invited to participate. Write on the flipchart (or blackboard) a statement of the subject or problem that will be discussed. This is often presented as a question. Choose one person to write down the ideas generated. Ideas should be written concisely but without paraphrasing. The recorder should state the idea in the words she has written to ensure that it expresses the meaning intended by the originator. Choose one person to facilitate the process. This involves encouraging participation by everyone and maintaining a criticism free, uninhibited atmosphere. Encourage even wild and seemingly ridiculous ideas. After 5 to 20 minutes the facilitator ends the session Review the list from top to bottom to ensure everyone understands the ideas. Eliminate from the list any duplications. Remove any obviously ridiculous suggestions. 11 PATENTS In the 1920s, engineers at Sperry Gyroscope Company developed a clever design for a bearing that would hold the end of the gyro shaft in position with great accuracy both axially and laterally, would support the gyro, and would have low friction. – It was patented and put into service with great success. – However, in 1965 the same basic design was discovered in a notebook belonging to Leonardo da Vinci dating from about 1500. A low friction bearing from da Vinci's notebook. [Ullman 1992] 12 SOURCES FOR CONCEPT IDEAS REFERENCE BOOKS AND TRADE JOURNALS http://www.machinedesign.com/ http://www. sae.org/ 13 SOURCES FOR CONCEPT IDEAS – EXPERT HELP 14 FUNCTIONAL DECOMPOSITION TECHNIQUE Step 1: Find the overall function that needs to be accomplished. Goal is to generate a single statement of the overall function based on the customer requirements. All design problems have one or two "most important" functions. These must be stated in a single concise sentence. Example: portable kayak Design a kayak that can be folded into a package small enough to fit in a trunk of a car Step 2: Decompose the function into subfunctions (perform functional decomposition). Goal is to refine the overall function statement as much as possible. Guidelines: 1. Document what not how. 2. Use standard methods and notations whenever possible for describing subfunctions. 3. Consider the logical relationships between the functions to determine their sequence. 4. Match inputs and outputs in the functional decomposition. 5. Break the main function down as finely as possible using a block diagram. 15 FUNCTIONAL DECOMPOSITION TECHNIQUE unpack Use unpacked pack Foldable kayak Allows reduction in size when transported and stored Customer requirements Product functions satisfying customer requirements 16 FUNCTIONAL DECOMPOSITION TECHNIQUE Use unpacked unpack pack First level decomposition unpack Second level decomposition Unfold skeleton Pump up Assemble form smaller components Pump up Third level decomposition ... ... ... Decomposing top level function into subfunctions 17 FUNCTIONAL DECOMPOSITION TECHNIQUE AND MORPHOLOGICAL ANALYSIS* Functional decomposition is used to identify the necessary product functionality Morphological analysis is used to explore alternative means and combinations of achieving that functionality. For each element of product function, there may be a number of possible solutions. The morphological chart is prepared and used to develop alternative combinations of means to perform functions and each feasible combination represents a potential solution. * Morphology: The science of the form and structure 18 DEVELOPING CONCEPTS FOR EACH FUNCTION Goal is to generate as many concepts as possible for each of the functions identified in the Functional Decomposition process. If there is a function for which only one conceptual idea exists, then this function needs to be reexamined because there are very few functions that can be fulfilled by only one concept). 19 DEVELOPING CONCEPTS FOR EACH FUNCTION Steps: List product functions (functional decomposition) List the possible 'means' for each function (morphological analysis) Chart functions and means and explore combinations unpack Unfold skeleton Pump up Assemble form smaller components 20 Functional decomposition of a wood splitter – in class exercise 21 COMBINING CONCEPTS INTO SINGLE CONCEPTUAL DESIGN hold on ice secure Concept 1 Concept 2 Concept 3 Concept 4 Concept 1 Concept 2 Concept 3 Concept 4 Function Design concept Goal is to select one concept for each function and combine those selected into a single complete conceptual design. Abstract concepts must now take some form, most often the form of sketches and comments. 22 Functional decomposition Morphological analysis 23 Functional decomposition Morphological analysis 24 SKETCHES AND COMMENTS Terminal cover assembly 25 SKETCHES AND COMMENTS Assistive writing device. – Rough sketches made in the design notebook provide a clear record of the development of the concept and the product. 26 SKETCHES AND COMMENTS Initial sketches and final design for a reusable syringe. 27 SOME THOUGHTS ON CREATIVITY 1. Develop a confident attitude. [Buhl 1968] 28 SOME THOUGHTS ON CREATIVITY 2. Unlock your imagination. [Buhl 1968] 29 SOME THOUGHTS ON CREATIVITY [Buhl 1968] 3. Be persistant. "Invention is 95% perspiration and 5% inspiration" T. Edison 30 SOME THOUGHTS ON CREATIVITY 4. Develop an open mind. [Buhl 1968] 31 SOME THOUGHTS ON CREATIVITY [Buhl 1968] 5. Suspend your judgement. 32 SOME THOUGHTS ON CREATIVITY [Buhl 1968] 6. Set problem boundaries. 33 TECHNIQUES FOR EVALUATING CONCEPTUAL DESIGN Type of Comparison Technique Basis of Comparison Numerous Concepts Feasibility Judgment Gut Feeling Technology Absolute Readiness Assessment State of Art Go/no-go Screening Customer Requirements Relative Decision Matrix Method BEST CONCEPT 34 EVALUATION BASED ON FEASIBILITY* JUDGMENT What we think about it? Understanding + Experience * Feasibility: The quality of being doable 35 EVALUATION BASED ON TECHNOLOGY READINESS ASSESSMENT Objective - is to determine the readiness of the technologies that may be used in the design concept. Immature technology will lead to a poor-quality product or cancellation of a project due to cost overruns. Time-Line for Technology Readiness Technology Development Time Powered human flight 403 (1500 – 1903) Photographic cameras 112 (1727 – 1839) Radio 35 (1867 – 1902) Television 12 (1922 – 1934) Radar 15 (1925 – 1940) Xerography 17 (1938 – 1955) Atomic bomb 6 (1939 – 1945) Transistor 5 (1948 – 1953) Digital camera 30 1965 - 2004 High temperature super conductor ? 1987 - ? Electric car 1900 - ? ….. 36 EVALUATION BASED ON TECHNOLOGY READINESS ASSESSMENT Six measures to determine if a technology is mature: 1. Can the technology be manufactured with known processes? 2. Are the critical parameters that control the function identified ? 3. Are the safe operating parameters known ? 4. Have the failure modes been identified ? 5. Does hardware exist that demonstrates positive answers to the above four questions ? 6. Is the technology controllable throughout the product's life cycle ? 37 EVALUATION BASED ON TECHNOLOGY READINESS ASSESSMENT Displacement on Demand has been in works for the last 25 years….. finally: GM announces that the 2005 model year GMC Envoy XL, Envoy XUV and Chevrolet trailblazer EXT will be the first vehicles to showcase its innovative Displacement on Demand fuel-saving technology, which enhances fuel economy without compromising performance or the ability to carry heavy loads. Displacement on Demand is to be a standard feature in the vehicles' optional Vortec 5300 V-8 engine. The technology, which boosts the Vortec engine's fuel efficiency by 8 percent, is also to be introduced in other GM engines in the 2006 model year. 38 EVALUATION BASED ON TECHNOLOGY READINESS ASSESSMENT 2000 2010 Hybrid car 39 EVALUATION BASED ON TECHNOLOGY READINESS ASSESSMENT http://www.veva.bc.ca/enfield/enfield1.jpg http://www.dieselstation.com/pics/2011-Holden-Volt-car-pics.jpg 2004 2010 Electric car 40 EVALUATION BASED ON TECHNOLOGY READINESS ASSESSMENT Film camera Digital camera 41 EVALUATION BASED ON TECHNOLOGY READINESS ASSESSMENT Incandescent Luminescent LED 42