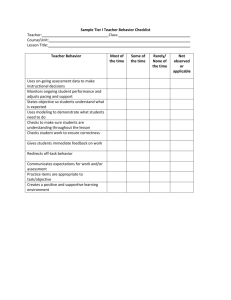

Checklist DA40 IFR

advertisement

IFR Checklist G-SOHO Diamond DA40 D Flight Deck and Electrical Checks External Checks Port Wing and Fuselage, Tail Starboard Fuselage and Wing Front Section and Nose Gear Before Starting Engine Checks Engine Starting After Start Checks Taxi Checks Radio Checks Power Checks Pre-Takeoff Checks In-Flight Checklist 1 2 3 3 4 5 5 6 6 6 7 Flight Deck and Electrical System Checks 1. Electric Master OFF 2. All electrical switches OFF 3. Engine Master OFF 4. ECU Swap AUTO 5. Flap selector UP 6. HIS / Remote Compass SLAVE 7. Circuit breakers all IN 8. Power lever check travel, set IDLE 9. Emergency fuel valve NORMAL, locked, wired 10. Trim check sense and set to T/O 11. Controls full and free travel 12. Rudder pedals no foreign objects, check travel 13. Electric Master ON 14. Fuel contents check, >15 USG use alt. means 15. Panel and internal lights ON, check, then OFF 16. Pitot heater ON 17. External lights ON (Nav, Strobes/anti-c., Ldg) 18. External lights check (Nav, Strobes/anti-c., Ldg.) 19. Pitot head check warm outside back on flight deck 20. External lights OFF (Nav, Strobes/anti-c., Ldg) 22. Pitot heat OFF 23. Electric Master OFF 24. Fire extinguisher, first aid kit check date, full, stowed 1 – Flight Deck and Electrical Checks Below Port Wing 1. Torch, fuel strainer Present 2. Step Secure 3. Gascolator drain 4. Antenna secure 5. Air intake clear 6. Wheel Check fairing, tire, creep mark 7. Fuel sump drain Port Wing 1. Stall warning check 2. Fuel cap check contents, secure 3. Pitot/static probe holes clear 4. Light covers secure 5. Wing surfaces, leading edge check 6. Wing tip secure, lights, 2 static wicks 7. Aileron movement, hinges, ctl rod 8. Fuel vent clear 9. Wing flap counterweight, hinges, ctrl rod Port Fuselage, Tail section 1. Canopy and rear door secure 2. Fuselage check 3. Antennas (1 top, 4 bottom) secure 4. Elevator movement, hinges, links, 2 wicks 5. Rudder movement, hinges, links, 1 wick 6. Rudder trim tab secure 7. Tail skid metal shoe present, undamaged 2 – External Checks Starborad Fuselage 1. Fuselage right side check 2. Rear window and canopy check Starboard Wing 1. Wing flap counterweight, hinges, ctrl rod 2. Fuel vent clear 3. Aileron movement, hinges, ctl rod 4. Wing tip secure, lights, 2 static wicks 5. Wing surfaces, leading edge check 6. Fuel cap check contents, secure Below Starboard Wing 1. Step Secure 2. Air intake clear 3. Fuel cooler intake as required 4. Wheel Check fairing, tire, creep mark 5. Fuel sump drain Front Fuselage and Nose Gear 1. Exhaust secure 2. Wheel check fairing, tire, creep mark 3. Air inlets (3) clear 4. Prop check edges, spinner secure 5. Air inlets (2) clear 6. Gearbox oil check level 7. Engine oil check level 8. Ground power cover closed 9. Yet another air intake clear 10. Whatever it is check 3 – External Checks (continued) Before Starting Engine 1. Rudder pedals adjusted and locked 2. Parking brake set 3. Passengers briefed 4. Seatbelts all on and fastened 5. Rear door closed and locked 6. Canopy closed or “cooling gap” 7. Compass serviceable, check deviation card 8. Instruments glasses, static check 9. Circuit breakers all set 10. Alternate static cock closed 11. Alternate air check movement, CLOSED 12. Power lever set friction, IDLE Start-up request 13. Electric Master ON 14. Engine instruments check 15. Annunciator panel check, press ACK button 16. Flight instruments erecting/flags, cage AI if required 17. HSI / compass aligned 18. Clock time check 19. Avionics Master ON 20. Intercom check 21. Transponder Standby 22. GPS check database 20. COMM 2 - ATIS/ATC obtain airfield data 21. Outside air temperature cross-check / plausible 22. Altimeters, Autopilot QNH – elevation check (60 ft) 23. COMM 2 - ready to start advise ATC 24. Avionics Master OFF 4 – Before Starting Engine Checks Engine Starting 1. Area clear check clear prop 2. Engine instruments check 3. Fuel temperature (if Diesel) not flashing / above –5 deg C 4. Water Level caution light check OFF 5. Strobe lights ON 6. Power lever check IDLE 7. ECU Swap AUTO 8. Engine Master ON 9. Glow Light wait until OFF 10. Avionics Master check OFF 11. Electric Master START 12. Oil Pressure rising within 3 seconds 13. Strobe lights OFF After Start Checks, Warm-Up 1. Cabin heater/defrost as required 2. Avionics Master ON 3. Stop watch (ADF timer) start 4. HSI, compass aligned 5. ADF set for taxi checks 6. Position lights ON (sunset-sunrise) 7. Flaps Check all positions, indicators 8. GPS ENT, check needles, no flags, ENT Now is a good time to set up the route in the GPS 5 – Engine Starting and After Start Checks Before Taxi Checks 1. Engine Warm-up 2 minutes since start 2. Idle RPM 890 RPM +-20 3. Engine temperature check 4. COMM 1 switch radios 5. ATIS obtain latest 6. Altimeters QNH – elevation check (60 ft) 7. Autopilot set QNH 8. COMM 1 Request Taxi to run-up area Taxi Checks 1. Max 1400 rpm until oil and coolant in green range 2. Brakes check P1 and P2 2. Turn-Ball-AI indications 3. HSI-ADF-Compass indications Radio Checks 1. ADF function checks 2. NAV1 GPS, VOR, ILS function checks 3. NAV2 GPS, VOR, ILS function checks 4. DME function checks, transfer check 5. Marker beacon receiver press to test 6. Transponder check pressure altitude 6 – Taxi and Radio Checks Power Checks 1. Parking brake check ON 2. Front canopy closed and locked 3. Door warning light OFF 4. Engine Indications acceptable 5. Fuel temperature (if Diesel) in green range / min +5 deg C 6. Throttle friction adjusted as required 7. Power Lever MAX 8. Oil pressure check in green range 9. RPM 2240-2300 10. Power indicator 90-100% 11. Alternate air effective, then OFF 12. Power lever IDLE, 890 RPM +-20 13. ECU Test - ECU A, ECU B, CAUTION - ECU BACKUP UNSAFE - ECU B checks - ECU A checks - ECU A, ECU B, CAUTION - ECU BACKUP UNSAFE press and hold blinking blinking light blinking, prop cycling light blinking, prop cycling OFF blinking 14. ECU TEST RELEASE 15. ECU SWAP ECU B, check engine, AUTOMATIC 7 – Power Checks Pre-Takeoff Checks 1. Charts: SID, re-land, en-route available 2. A.T.I.S. check latest 3. Altimeters aerodrome QNH 4. Autopilot aerodrome QNH 5. ATC clearances obtain 6. Transponder set code 7. Departure briefing satisfied 8. Nav aids – GPS - comms set 9. Canopy final check, front and aft 10. Cabin heat/defrost as required 11. Auto pilot OFF 12. Trimmers check electric trim, set for take-off 13. Flaps set T/O 14. Controls full and free 15. Engine instruments normal 16. Fuel contents sufficient 17. Crew take-off brief completed 18. Ready for Departure report 8 – Pre-Takeoff Checks 1. A HSI-compass Aligned, RWY heading 2. T Transponder ALT 3. P Pitot heat ON 4. L Landing light, Strobes ON 5. Throttle full power 10 sec 6. Engine Instruments check RPM, Power, Ts & Ps 7. Brakes release 8. Airspeed rising Mass 1,874 2,205 2,535 Vr 49 55 59 Flaps T/O Vx Vy 54 60 68 Takeoff 1 Vr Clean Vx Vy 59 66 73 1. Airspeed 59-73 kts 2. Flaps retract 3. Navigation aids Identify - bearings 4. Airframe/engine icing check 5. Altimeter No. 1 (pilot’s) QNH or 1013.2 as required No.2. aerodrome QNH 8. 1000 ft - Landing light OFF 9. SID/SAFETY/MSA altitudes achieved After Take-off And Climb Checks 2 Cruise Performance 2b 1. F Fuel quantity HOWGOESIT, 2. R En-route navigation aids set & identified 3. I Airframe/engine icing check 4. E Temperature & pressures check 5. D HSI slaving - compass check 6. A Volmet/ATIS/QNH obtain QNH 7. balance tanks Altimeter No. 1 (pilot’s) check set as reqd Altimeter No. 2 update QNH Minimum safe altitudes check Descent anticipated descent checks Cruise Checks 3 1. Minimum safe altitude checked 2. ATIS or latest weather obtained / recorded 3. Aerodrome minima check / recorded 4. STARS & approach charts crew briefing 5. Throttle reduce 8. Altimeter No. 2 set aerodrome QNH Pilot’s 1013.2 or QNH 8. Airframe/engine icing check 9. Fuel sufficient Descent Checks 4 1. Approach procedure crew briefing 2. Approach/go-around aids set & identified 3. Crew/passengers all secure 4. Landing light ON 7. HSI slaving - RMI - compass checked 8. Altimeter No.2. check aerodrome QNH Pilot’s 1013.2 or QNH 9. Airframe/engine icing check / operate if reqd 10. Temperatures & pressures check Approach Checks 5 2. Alternate air ON if wing ice 3. Altimeters aerodrome QNH, x-check 4. HSI slaving - RMI - compass check 6. Decision altitude checked - recorded 5. Power/Airspeed Reduce to 95 kt 6. 1 NM / quarter scale below 108 - flaps T/O 6. FAP check altitude 8. DME or OM or beacon altimeter check 12. “Reds, Blues & Greens” for landing Pre-Landing Checks 6 1. Power Prop fine, MP 36” 100% 2. 3. Flaps rate of climb Positive retract identified 3. 4. Positive rate of climb Flaps identified retract 4. 5. Undercarriage below 110 kt A.T.C. UP report going around 5. ! 7. Adequate altitude Navigation aids gain set 32" 2500 identify - bearings rpm 6. 8. A.T.C. & engine Icing Airframe report /going check operate around if reqd 7. 9. Navigation altitude SID/safety aids identify - bearings achieved 8. 10. Airframe &No. Altimeter engine 1 (Pilot’s) Icing checkor QNH / operate 1013.2 as if reqd reqd 9. SID/safety altitude No.2 achieved QNH aerodrome 10. ! Landing 11. AltimeterLight No. 1 (Pilot’s) QNH or 1013.2 as reqd OFF 13. aerodrome QNH achieved No.2 Minimum Sector Altitude 11. ! Pressures 14. Electric fuel&pump Temps >1000' OFF check 12. 15. Landing Light Prepare for Airfield Approach Checks OFF 13. Minimum Sector Altitude achieved 14. Pressures & Temps check 15. Prepare for Airfield Approach Checks Go-Around Checks 7 1. Flaps retract 2. Landing light OFF 3. Pitot heat OFF 4. Transponder set to standby 7. On stand - Radio Master OFF - GPS OFF - Magnetos live & dead check - Mixture control I.C.O. - Magneto switch OFF - Beacon leave ON - Electric fuel pump OFF - Master Switch OFF - Headsets OFF 8. Times record 9. Gust lock, aircraft secure as required 10. Technical Log complete - sign After Landing Checks 8 In-Flight Engine Fire 1. Mixture I.C.O. 2. Fuel selector off 3. Fuel pump off 4. Magnetos off 5. Throttle fully open 6. Cabin heat / defroster closed 7. Prop stop if possible 8. Emergency descent full flap, 112 kts If fire stops: 9. Flaps retract 10. Undercarriage override ENGAGE 11. Airspeed 80 kts 12. Select landing area 13. Continue with Power Off Landing checklist If fire persists: 14. Select landing area 15. Transponder 7700 16. ATC Mayday call 17. Passengers Brief 18. Seatbelts tight 19. Undercarriage UP for water, rough terrain otherwise DOWN , 3 greens 20. Master switch OFF Emergency – Engine Fire 9 In-Flight Engine Failure 1. If after power reduction Lean until engine restarts Maintain EGT 1350 or above 2. Undercarriage override ENGAGE 3. Airspeed Convert into maintaining altitude 4. Best glide airspeed 80 kts 5. Select landing area Attempt restart (unless after fire or catastrophic failure): 6. Electric fuel pump ON 7. Fuel selector select tank with fuel / switch 8. Magnetos check BOTH 9. Throttle cruise setting 10. Mixture rich 11. Alternate air OPEN 12. Magnetos check each magneto 13. Engine indications check fuel flow, MP, etc. If unsuccessful, continue next page (Power Off Landing checklist) Emergency – Engine Failure 10 Power Off Approach and Landing 1. Best glide airspeed 80 kts 2. Prop lowest RPM (fully back) 3. Transponder 7700 4. ATC Mayday call 5. Passengers Seat backs Seat belts Glasses / false teeth Brace 6. Seatbelts tight 7. Electric fuel pump OFF 8. Fuel selector OFF 9. Magnetos OFF 10. Throttle CLOSED 11. Mixture I.C.O. 12. Undercarriage UP for water, rough terrain otherwise DOWN , 3 greens 13. Flaps set 14. Master switch OFF Emergency – Power Off Landing 11 Electrical Fire 1. 2. 3. 4. 5. 6. 7. 8. 9. Master switch Cabin wall vents Cabin heat, defrost Electrical services Circuit breakers Master switch One VHF radio ATC Smoke / Fire ceases 10. Land as soon as practical OFF OPEN CLOSED all OFF check ON, check no smoke ON advise intentions restore essential services one by one Alternator Failure 1. 2. 3. 4. 5. 6. 7. Ammeter, ALT FAIL light cross-check ALT switch OFF Electrical load Reduce to minimum ALT circuit breaker check / reset if required ALT switch ON Ammeter, ALT FAIL light check If power not restored, advise ATC and land as soon as practical Persistent Alternator Overload (> 5 minutes) 1. 2. 3. 4. 5. 6. ALT switch BAT switch Ammeter If load not reduced: BAT switch ALT switch Electrical load Land as soon as practical ON OFF Check load reduced ON OFF Reduce to minimum Emergency – Electrical 12 High Oil Temperature 1. 2. Oil Pressure check Land at nearest airport. Prepare for possible engine failure Low Oil Pressure 1. 2. 3. Oil Temperature check Land at nearest airport. Prepare for possible engine failure If complete loss of oil suspected, consider off-airport landing Turbocharger Failure 1. 2. 3. 4. 5. 6. Manifold pressure Throttle Propeller control Mixture Exhaust Land as soon as practical check full fine / full forward adjust as required check for smoke (oil leak) Prop Overspeed 1. 2. 3. 4. 5. Throttle Airspeed Oil pressure Propeller control Land as soon as practical retard – max 2700 RPM reduce if required check full decrease, check for control Manual Gear Extension 1. 2. 3. 4. 5. 6. 7. 8. Master switch Circuit breakers Radio lights Gear indicator bulbs Airspeed Undercarriage selector Emergency gear lever Fishtail aeroplane check ON CHECK check OFF (in daytime) / adjust CHECK below 92 kts DOWN EMERGENCY DOWN Emergency – Engine, Gear Mass and Balance Schedule as of 31/03/2004 Weight (lbs) 2,342 Loading Station Empty Arm (in) 80.53 Front Baggage 42.00 Seat Row 1 85.50 Seat Row 2 119.10 Seat Row 3 157.60 Rear Baggage 178.70 Fuel usg x 6 Moment (lbs x in) 188,595 Mass and Balance Envelope 80 3400 82.75 usg x 6 3200 -1,598 Total Take-Off Trip fuel 3600 3400 Total Ramp 94.00 95 91.4 94.00 -17 90 3600 3200 Taxi fuel 85 94.00 3000 3000 2800 2800 2600 2600 Total Landing MTOW 3,600 Fuel Fuel kg -> lbs l -> lbs l -> usg 70 usg 102 usg x 2.2 x 1.58 ÷ 3.785 9 – Mass and Balance 420 612 94.00 94.00 39,480 57,528 2400 2400 Empty 78 80 85 90 95 Electrical System Schematics Hot Battery Bus Battery Bus Main Bus Essential Bus Essential Avionics Bus Avionics Bus 1 – Flight Deck and Electrical Checks