Fire Stops

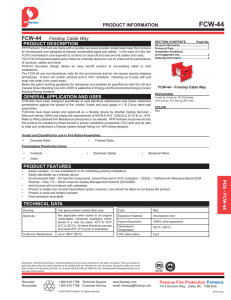

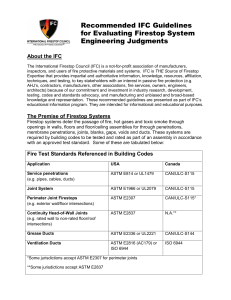

advertisement

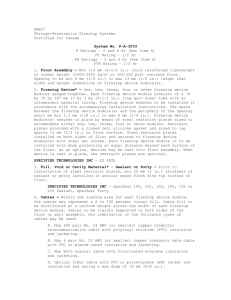

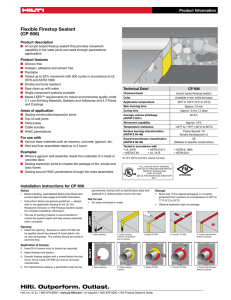

Fire Stops • Five Reasons for Firestoping • • • • • Save lives Buys Time Protects Critical Systems Liability Protects investments • Designed to stop: • • • • Fire Smoke Cold gas/noxious fumes Super heated toxic gases Fire Walls • When cable is to be pulled through a firewall, a hole must be drilled through the firewall • After the hole is drilled, the penetration is usually sleeved • After the cables have been pulled through the conduit, the conduit must be sealed with an approved fire-stop material Copyright 2004 Panduit Network Infrastructure Essentials Firewall Rock wool or mineral batting (as required) Sleeve or Conduit Flange Intumescent (expands when heated) caulk or putty Communications Cabling Wall to be penetrated Do not exceed 50% fill ratio (cable area to conduit area) Leave 4-inches to 12-inches of conduit protruding from wall (check local codes) Fire Stops • Penetrations • Through • Membrane (i.e., metal outlet box) • Warnings • Firestops are tested as an assembly • Tested as an assembly • If not installed per manufactures specifications the testing is invalid • Installers may be held personally liable • Substitute materials aren’t part of the assembly • Types of Products • Mechanical • Mortar/Compounds Fire Stops • Types of Products • • • • • • • • Composite Sheets Collar/devices Blankets Caulks/sealants Putty Wrap strips Pillows/bags Sprays Example usage: Backfilling • Backfilling is the placement of fire-stop solution products into the penetration after the cabling has been installed in the opening. All openings around a conduit and holes must be sealed completely Fire Stops • Fire Stop Material Traits • Endothermic • This trait allows a fire stopping material to emit water vapor as it burns to cool the material prevent the transfer of heat to the far side of the firewall • Intumescent • Swells when heated • Fills spaces around or in a penetration • Ablative • Develops a hard covering when heated important in resisting hose sprays of pressurized water Fire Stops • Selecting Firestop Materials/Systems • Selection Criteria • • • • • Local authorities Qualification Testing Installation efficiency Maintenance convenience Future cable changes • Some Electrical Apparatus are Fire-rated • i.e., boxes, junction boxes, breaker panels, fixtures, and poke-thrus • Firestop all non-rated apparatus Fire Stops • Selecting Firestop Assembly • Identify type of barrier to be penetrated • Floors, Walls, combinations of walls and floors • Construction of barrier • • • • • • • • • • Concrete drywall wood etc. Penetrating items Size/shape of Opening Orientation of penetrating items to the opening Water exposure Movement/vibration of the penetrating items Required ratings F, H, and T Fire Stops • Non-mechanical Firestop Systems • Firestop Putty (See Nelson FSP in front of Manual) • Caulks (See Nelson CLK in front of Manual) • Cementitious materials (See Nelson CMP in front of Manual) • Intumescent sheets (See Nelson CPS in front of Manual) • Silicon foam (See Cisco CBTs) • Premanufactured pillows (See Nelson PLW in front of Manual) Fire Stops • Non-mechanical Firestop Systems • Prefabricated intumescent collars (See Nelson PCS in front of Manual) • Sprays (See Nelson FSC in front of Manual) • Blankets (see Cisco CBTs)