Operations Management: Process Strategy Presentation

advertisement

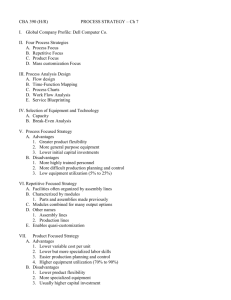

Operations Management Process Strategy Process Strategies Involves determining how to produce a good or provide a service within constraints Objective Meet or exceed customer requirements Meet cost & managerial goals Has long-run effects Production efficiency Product & volume flexibility Cost & quality Fit of Process, Volume, and Variety Low-Volume (Intermittent) High Variety One or few units per run, high variety (allows customization) Changes in modules Modest runs, standardized modules Low Variety; Changes in attributes (such as grade, quality, size, thickness, etc.) Long runs only Repetitive Process (Modular) Process focus projects, job shop, (print, carpentry) Standard Register High-Volume (Continuous) Mass Customization (difficult to achieve, but huge rewards) Repetitive (autos, motorcycles) Harley Davidson Dell Computer Co., Levis Jeans Product focus (commercial baked goods, steel, glass) Steel, Cement Process-Focused Strategy Facilities are organized by process Similar processes are together Example: All drill presses are together Low volume, high variety products ‘Jumbled’ flow Product A Operation Other names Job shop 1 Product B 2 3 Process-Focused Example Custom Woodworking Shop Cutting Planing Shaping Assembly Sanding Finishing 1 Job A Job B 1 2 5 6 5 6 3 2 4 3 4 Drilling Turning 7 Process Focus - Pros & Cons Advantages Greater product flexibility More general purpose equipment – equipments not dedicated to one product Disadvantages High production cost per unit More difficult production planning & control Low equipment utilization (5% to 25%) Process-Focus Examples Bank Hospital Machine Shop Repetitive Focused Strategy Facilities often organized by assembly lines Characterized by modules Parts & assemblies made in modules Modules combined for many output options Other names Assembly line Production line E.g. auto-manufacturing, pc’s, house-hold appliances, etc Assembly Line Example Raw Material Components 4 2 Assemblies 1 Raw Material 3 Components Product/Material Flow Production Operation 5 Subassem. Fin. Goods 7 Repetitive Focus - Considerations Product focused process that uses modules More structured than process-focused, less structured than product focused Enables semi-customization Using modules, it enjoys economic advantage of continuous process, and custom advantage of lowvolume, moderately high-variety model Repetitive Focus - Examples Fast Food Clothes Dryer McDonald’s over 95 billion served Truck Repetitive Focus Product-Focused Strategy Facilities are organized by product High volume, low variety Conversion or further processing of undifferentiated materials such as petroleum, chemicals, or beer Follows a predetermined sequence of steps, but flow is continuous rather than discrete – highly standardized Other names Line flow production Continuous production Production Process at NUCOR Steel Product Focus - Pros & Cons Advantages Lower production cost per unit Lower but more specialized labor skills Easier production planning and control Higher equipment utilization (70% to 90%) Disadvantages Lower product flexibility More specialized equipment Product-Focused Examples Soft Drinks (Continuous, then Discrete) Paper (Continuous) Mass Customization Using technology and imagination to rapidly mass-produce products that cater to unique customer desires Under mass customization the three process models become so flexible that distinctions between them blur, making variety and volume issues less significant