BIODIESEL – WHY, HOW AND… SO WHAT?

advertisement

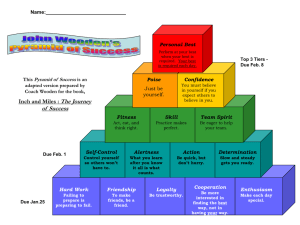

BIO DIESEL-WHY & HOW ? N.R.Raje NRRaje Feb 06 The Indian Petroleum Scenario Consumption of petroleum products Import of crude & POL (2003-04) Production of crude Consumption of HSDO & LDO Consumption of motor gasoline (petrol) NRRaje Feb 06 -120 MMT - 90 MMT - 33 MMT - 45 MMT - 10 MMT Oil Economy Oil import constitutes a major part of our trade deficit and has an enormous impact on our economy and creation of new jobs We spent annually more than 150,000 crores on import of petroleum Some day we may be faced with an oil crisis that is not temporary; today oil field discovery and production is on the decline. Developing a strong market for bio diesel would have tremendous economic benefits Investments in biodiesel technology may ensure that we have transportation fuel options and we will not be so vulnerable NRRaje Feb 06 Bio Fuels Oxygenated organic compounds from cellulosic biomass Bio ethanol, Biodiesel Others include: bio methanol, DME, ETBE, pyrolysis oils, FischerTropsch fuels Can provide a market share of ~15% Why Bio Fuels? SECURITY OF SUPPLY SUSTAINABILITY REDUCTION OF GREEN HOUSE GAS EMISSIONS REGIONAL (RURAL) DEVELOPMENT SOCIAL STRUCTURE & AGRICULTURE NRRaje Feb 06 Bio Diesel Made by chemically combining any natural oil or fat with an alcohol Most European Countries, North America and Canada have active Biodiesel programmes France currently the largest producer USA produced 30 million gallons in 2004. NRRaje Feb 06 VEGETABLE OILS AS FUELS • “THE USE OF VEGETABLE OILS FOR ENGINE FUELS MAY SEEM INSIGNIFICANT TODAY. BUT SUCH OILS MAY BECOME IN COURSE OF TIME AS IMPORTANT AS PETROLEUM AND COAL TAR PRODUCTS OF THE PRESENT TIME” - Rudolf Diesel at the Engg Society of St. Louis, 1912 NRRaje Feb 06 Wide Acceptance By diesel vehicle industry Audi BMW Deutz Iseki Massey-Ferguson Puegot Renault Skoda Steyr Volvo Case John Deere Mercedes-Benz Same Valmet Claas Kubota Nissan Seat Volkswagen By the fuel trade; e.g, Texaco, Shell, Total By the end-user – bus companies, taxi fleets, forestry enterprises, boat owners More than 100 production sites (capacity 500-120,000 tons/annum) NRRaje Feb 06 NRRaje Feb 06 NRRaje Feb 06 Raw Materials Rapeseed, the major source (>80%) Sunflower oil (10%, Italy and Southern France) Soybean oil (USA) Palm oil (Malaysia) Linseed, olive oils (Spain) Cottonseed oil (Greece) Beef tallow (Ireland), lard, used frying oil (Austria), Feb 06 Jatropha (Nicaragua), NRRaje Guang-Pi (China) Bio diesel Production Basics Three basic routes Base catalysed transestrification Acid catalysed transestrification Conversion of oil to fatty acids and then to Easter by acid catalysis NRRaje Feb 06 Bio Diesel - Manufacture CH2-O-COR CH2-OH | CH-O-COR KOH, rt, 6h + 3R’OH | 3RCOOR’ + CH-OH | | CH2-O-CO-R CH2-OH (100 kg) (10.55 kg) (.1 kg) (100 kg) (10.55 kg) Oil Alcohol KOH Bio Diesel Glycerin NRRaje Feb 06 Base Catalysed Transestrification Most popular of all method >90% of all bio diesel by this method Low temperature ( 150o F) and pressure (20 PSI) High conversion (>98%) Minimum side reactions Direct conversion- No intermediate step Ordinary material of construction NRRaje Feb 06 Effect of Free Fatty Acid (FFA) Soap formation Excessive utilization of alkali Loss of yield Slower reaction Incomplete conversion For best conversion FFA should be lower than 0.8% NRRaje Feb 06 Troubleshooting in high FFA containing oils Formation of soap Reduction in catalyst efficiency Separation process is difficult Low yield of Easter (Bio diesel) Therefore, two stage method was used Esterification of FFA with mineral acid Tranesterification with lye NRRaje Feb 06 Bio diesel Process Flow Diagram NRRaje Feb 06 US & European specification NRRaje Feb 06 Indian Specification (BIS) for Bio Diesel NRRaje Feb 06 DIESEL vs BIODIESEL Me Ester Density 150C, g/l Viscosity 400C, mm2/s Cetane number Iodine value Lower heating value (MJ/kg) Palm oil 872-877 4.3-4.5 64.3-70.0 52 37 Rapeseed oil 882 4.2 51-59.7 114 37.2 Soybean oil 880 4.0 45.7-56.0 131 37.1 Diesel fuel 830-840 1.2-3.5 51 - 42.7 NRRaje Feb 06 BIODIESEL / DIESEL DATA PROPERTIES Diesel IS 1460 Specification Biodiesel ASTM 6751 Specification Proposed BIS Specifications (B100) DATA B5 DATA B20 DATA (B100) Density (g/cm3) 820 to 870 NA 860-900 834.2 854.7 885.7 Carbon Residue (100%) % mass Max. 0.3 Max 0.05 Max 0.05 0.04 0.01 0.01 Sulphated Ash , % mass Max. 0.01 Max 0.020 Max 0.02 0.002 0.002 0.001 Total Sulfur, % mass Max. 0.25 Max 0.05 Max 0.005 0.02 0.04 NIL Cetane Number Min. 48 Min 47 Min 51 50.4 54.6 56.6 Flash Point,0C Min. 35 Min 100 Min 120 39.5 77 103 Copper Corrosion Max. 1 No. 3b max Max 1 1 1 1 Viscosity, 40 0C(cSt) 2.0 to 5.0 1.9-6.0 2.5-6.0 2.497 3.25 4.10 Neutralization Value (mg) Max. 0.2 Max 0.8 Max 0.50 0.1 0.2 0.04 Free Glycerin,% mass N/A Max 0.02 Max 0.02 NA NIL 0.01 Total Glycerin,% mass N/A Max 0.24 Max. 0.25 NA 0.05 0.22 CFPP, (0C) Max. 6(W) NA NA 0.0 -1 0.0 Pour Point deg C 3 0C NA NA -6 -3 NA Water and sediments, (% mass) NA 0.01 NA 0.05 0.04 <0.01 NRRaje Feb 06 HEAT OF COMBUSTION Petro-diesel 130,500 BTU/gallon Biodiesel (soybean) 128,000 Petro-diesel 18,400 BTU/lb Biodiesel (Rapeseed) 17,900 BTU/lb “ Net fuel combustion efficiency is increased – most noticed at low rpm and high engine load NRRaje Feb 06 POWER OUTPUT Small difference in overall power output SRI Study (Cummins truck engine) 20% Blend 98.5% relative to petrodiesel Neat 92% Tennessee Study (Volvo marine engine, 110 HP) Neat biodiesel – power output 2-7% lower At max throttle (3800 rpm), both fuels performed the same At the lowest engine speed (1855 rpm), at full throttle and heavy load, power output was 13% higher NRRaje Feb 06 FUEL CONSUMPTION Biodiesel contains ~10% oxygen Consequently, slight increase in the apparent fuel consumption rate 2% for B20 blend; 14% for B100 (Cummins engine) Brake-specific fuel consumption figures – Petrodiesel 0.43 lb/HP-hr – B20 0.44 “ – B100 0.50 “ NRRaje Feb 06 LUBRICITY LONG TERM ENGINE WEAR EXTENSIVELY STUDIED IN EUROPE & THE US EXXON STUDY B20 PROVIDE, SIGNIFICANT, QUANTIFIABLE IMPROVEMENTS IN WEAR (193 MICRON SCAR VERSUS 492 MICRON SCAR FOR PETRODIESEL) FRICTION – 0.13 MICRON SCAR (B20); 0.24 MICRON SCAR (DIESEL) FILM FORMING ABILITY – 93% FILM (B20); 32% FILM (DIESEL) B20 COMPARED FAVOURABLY WITH EXXON’S OWN LUBRICITY ADDITIVE COMMENTS FROM STANADYNE AUTOMOTIVE Inc: 1. “LUBRICITY TEST HAVE SHOWN THAT UPTO 2% OF BIODIESEL IS ENOUGH TO MAKE AN DISTILLATE FUEL FULLY LUBRICIOUS”; 2. “SINCE BIODIESEL IS A FUEL ITSELF, THERE ARE NO TECHNICAL ISSUES RELATED TO OVERDOSING WHICH ARE PRESENT WITH CONVENTIONAL LUBRICITY ADDITIVES” IOC R&D HAS ALSO DONE EXTENSIVE STUDIES ON LUBRICITY ASPECTS-PAPER PRESENTED IN THE LAST WPC NRRaje Feb 06 EXHAUST EMISSIONS Tests conducted at southwest research institute, Texas on a Cummins n14 diesel truck engine (direct injected, 4-stroke, 6 cylinder Regulated emissions – Total hydrocarbons (hc) – Carbon monoxide (co) – Oxides of nitrogen (nox) – Particulate matter (pm) – Polycyclic aromatic hydrocarbons (pah) – Nitrated pah Results compared with those of #2 diesel NRRaje Feb 06 EMISSIONS (contd) • • • • • • • • HC emissions essentially eliminated CO emissions reduced by 50% NOx emissions 13% higher PM reduced by 30% – Reduced insolubles in PM by more than 80% – Soluble organic fraction increased by ~40% – Net redn in particulates, 30% Sulfate emissions essentially eliminated Also quantitated individual hydrocarbons species (C1-C12) and also aldehydes and ketones Assessed the ozone forming potential of total speciated hydrocarbons – For neat bio diesel, the total speciated hydrocarbons, ~50% less – Ozone forming potential of these HC reduced by the same extent Significant reduction in most of the aldehyde components NRRaje Feb 06 – Formaldehyde and acetaldehyde, 30% lower LIFE CYCLE ANALYSIS An inventory of energy flow to and from the environment during the life cycle of a product (“cradle to grave”) Study conducted by the National Renewable Energy Laboratory, Colorado, USA Provides the fuel’s energy balance, its effect on greenhouse gas emissions and on the generation of air, water and solid pollutants for every operation carried out during its preparation and storage NRRaje Feb 06 LIFE CYCLE EMISSIONS – CO2 Biodiesel generates 573.96 g/bhp-h compared to 548.02 g/bhp-h for petroleum diesel The higher CO2 levels result from more complete combustion The overall life cycle emissions are 78.45% lower for biodiesel; direct result of carbon cycling by the soybean plants NRRaje Feb 06 CARBON TRADING POTENTIAL • • • • • Reduction in GHG (CO2) 1 Ton bio-diesel avoids Appx 3 ton CO2e Certified Emission reduction (CER) 1 ton of CO2e 1 CER @ US $ 5 75 p/ liter additional revenue NRRaje Feb 06 STORAGE, HANDLING Standard Handling And Storage Practice As With Petroleum Diesel NRRaje Feb 06 EFFECT ON ENGINE SEALS, GASKETS, HOSES Bio diesel has strong solvent properties – Natural rubber and soft plastics especially vulnerable – Problem substantially reduced for the B20 blend – The only hose and gasket material that is truly resistant to biodiesel is Viton NRRaje Feb 06 BIODIESEL vs OTHER ALTERNATE FUELS DIESEL CNG LNG METHANOL ETHANOL BIODIESEL ___________________________________________________________________________ Vehicle cost 10 5 5 5 5 10 Infrastructure 10 2 5 5 5 10 Safety 7 4 3 1 3 8 Operating range 10 5 10 10 10 10 Operating cost 10 5 7 5 5 7 Reliability 10 7 5 3 3 10 Customer acceptance 5 8 8 8 9 8 Funding assistance 1 10 2 0 2 2 Training cost 10 5 5 5 5 10 Fuel availability 10 10 5 5 5 6 Fuel quality 9 5 10 8 8 9 Fuel price stability 6 8 8 6 6 6 TOTAL 98 74 NRRaje Feb61 06 73 66 96 __ PROMOTION of Bio-diesel….. NRRaje Feb 06 Europe 1. EU announces total exemption (reduction) of tax on pure & low blended bio fuels for at least 6 years w.e.f. 01.01.2004 extendable for another 6 years. Effective Reduction in duty in Germany 587 $/MT 2. Adoption of Directive 2003/30/EC of The European Parliament And of The Council of 8th May 2003 promotion of the use of bio fuels for transport. NRRaje Feb 06 United States "Consumers and businesses need reliable supplies of energy to make our economy run so I urge you to pass legislation to modernize our electricity system, promote conservation, and make America less dependent on foreign sources of energy." -Mr.George W.Bush NRRaje Feb 06 United States A biodiesel tax incentive was included in the Final Energy Bill. 1 cent per % point of biodiesel blended with petroleum diesel. NRRaje Feb 06 Europe EU Finance Minister adopted a political agreement to allow Governments to exempt transport bio fuels,such as biodiesel,from Excise Duties applied to Conventional Fuels. EU target for bio fuels : At least 2% of total petrol & diesel within transport sector by 2005, to increase by 0.75% each year thereafter to reach 5.75% by 2010. EU announces exemption of Tax on pure & low Bio fuels for at least 6 years w.e.f. 01.01.2004 NRRaje Feb 06 Germany A total exemption from the Excise Duty on Mineral Oil for pure & blended Bio fuels w.e.f. January 2004 up to 31st December 2009,which is based on % of Bio fuels included in Final blend. Higher the proportion,greater the reduction. No excise tax for biodiesel substituting standard fuels,either unblended or blended with fossil diesel in the vehicle tank. The 2003 Budget Bill allows for a complete exemption of Excise Duties of up to 409 Euro / Kl on all fuels derived from bio mass including Biodiesel. Tax incentive for VOME (470 Euro/M3) includes Carbon tax incentive & only applies to pure VOME. Tax Incentive $ 607/ MT NRRaje Feb 06 France Biodiesel to substitute 5% of Diesel fuel by 2005. Excise Taxes on Petroleum products do not apply to Bio fuels. Tax incentive adopted for VOME mixed with diesel within allotted quota, 320,000 MT/year for Biodiesel. Tax Incentive $ 490/ MT NRRaje Feb 06 Austria The Austrian Law on Tax Reforms 2000 exempts the use of pure Bio diesel & the blending of it . 100 % tax exemption on pure Biodiesel 100% tax exemption if up to 2% biodiesel is blended with diesel fuel. Currently a tax incentive of 290 Euro/M3 applies to pure VOME used in motor fuel blends up to 2%. Tax Incentive $ 431/ MT NRRaje Feb 06 United Kingdom UK Government has EU targets to replace 2% fossil fuels by renewable fuels by 2005, to reach 5% by 2010. UK Government offered 20 pence per litre duty incentive for Biodiesel on January 1,2003. UK is authorized to apply a differentiated rate of Excise Duty to fuels containing Biodiesel Tax Incentive $ 205/ MT NRRaje Feb 06 Summary of Support EU Country Feedstock Price of Processing Total cost for Feedstock Cost of biodiesel Biodiesel in $/MT in $/MT in $/MT 1 2 3=(1+2) Austria Rapeseed oil 590 500 1,090 Finland Rapeseed oil 590 500 1,090 France Rapeseed oil 590 500 1,090 Germany Sunflower oil 565 500 1,065 Greece Rapeseed oil 590 500 1,090 Ireland Sunflower oil 565 500 1,065 Italy Sunflower oil 565 500 1,065 Portugal Sunflower oil 565 500 1,065 Spain Sunflower oil 565 500 1,065 Sweden Rapeseed oil 590 500 1,090 U.K. Rapeseed oil 590 500 1,090 NRRaje Feb 06 PROCESSING COST BREAK - UP Particulars $ / MT Other Chemicals 80 (Net of recovered Byproducts) Oil, Fuel, Electricity 100 Labour & other factory expenses 100 Depreciation 60 Interest 60 Processor's Margin 100 Total Processing Cost 500 Summary of Support /subsidy EU Country Diesel Price Duty on Diesel Total cost Subsidy given net of duty Diesel Price of biodiesel on biodiesel Austria Finland France Germany Greece Ireland Italy Portugal Spain Sweden U.K. $/MT 584 581 541 517 591 502 627 536 544 718 385 $/MT 353 433 486 588 306 525 504 374 366 435 1,060 $/MT 936 1,014 1,027 1,104 897 1,027 1,130 910 910 1,153 1,445 NRRaje Feb 06 $/MT 1,090 1,090 1,090 1,065 1,090 1,065 1,065 1,065 1,065 1,090 1,090 $/MT 431 625 490 607 Not Known Not Known 598 374 579 511 205 Biodiesel production remained flat until the creation of USDA’s Bioenergy Program in FY 2000 that caused production to jump from about 2 million gallons to 6.5 million gallons in FY 2001 The Farm Bill extends USDA’s Bioenergy Program to 2006 1000 gallons 16000 14000 Congress amends EPACT to include biodiesel 12000 10000 The National Soy Fuels Advisory Committee was Established in 1992 8000 6000 USDA started the Bio energy Program under the authority of the CCC Charter Act 4000 2000 0 2002 2001 2000 1999 1998 1997 1996 1995 1994 1993 1992 NRRaje Feb 06 Source: Anecdotal information and USDA, Farm Services Agency CAN BIODIESEL WORK IN INDIA? India with just 2.4% of global area supports more than 16% of the human population and 17% of the cattle population India is one of the largest importers of edible oil Where do we find the oil for biodiesel? A sustainable source of vegetable oil is to be found before we can think of biodiesel NRRaje Feb 06 JATROPHA THE ANSWER? • • Jatropha (Jatropha curcas, Ratanjyot, wild castor) thrives on any type of soil – Needs minimal inputs or management – Has no insect pests, not browsed by cattle or sheep – Can survive long periods of drought – Propagation is easy – Rapid growth; forms a thick live hedge after only 9 months of planting – Yield from the 3rd year onwards and continues for 25-30 years – Yield from established plantations in Brazil, 1.5 to 2.3 tons per hectare – 25% oil from seeds by expelling; 30% by solvent extraction – The meal after extraction an excellent organic manure (38% protein) According to the National Mission on Bio Fuels out of 197 million hectors,13.4 MH available for Jatropha plantation NRRaje Feb 06 NRRaje Feb 06 NRRaje Feb 06 BIODIESEL FROM JATROPHA 1 MILLION HECATRES OF WASTE LAND IS BROUGHT UNDER JATROPHA CULTIVATION – Can yield – 0.8-1 million tons of oil – For 66.9 MMT diesel (Projected 2011-12) – 13 MMT bio diesel for 20% blend – 11 MH land required – 11 million jobs NRRaje Feb 06 Initiatives taken by Govt Planning commission Committee formed Report Indian Railways – Planted 7.5 million Jatropha plants on railway track Bureau of Industrial Standards (BIS) has given specification for pure bio-diesel (B100) MOP&NG MSP of Bio-diesel Rs.25/- per liter 20 centres designated for blending Oil marketing companies to make available comprehensive industry guidelines “ Operation, Quality & Safety IOC R&D taken up extensive studies NRRaje Feb 06 Phase I Demonstration Project 4 laks ha has been phased in 3 years i.e. 80,000 ( 2006-07), 1.6 lakh (2007-08)and 1.6 lakh (2008-09) by the MORD The quality planting material for total 4 lakh ha areas is to be arranged by the NOVOD Board and DST Quality planting material means- The seed should be selected from superior plants having yield of 2 kg per plant and oil content should be more than 30% NRRaje Feb 06 TARGET OF BIO-DIESEL PRODUCTION Year Diesel Demand MMT Bio-Diesel @5% MMT Area for 5% Mha Bio-Diesel @10% MMT Area for 10% MMT Bio-Diesel @20% MMT Area for 20% Mha 2006-07 52.33 2.62 2.19 5.23 4.38 10.47 8.76 2011-12 66.90 3.35 2.79 6.69 5.58 13.38 11.19 2012-15 80.00 4.00 4.88 8.00 9.60 16.00 19.21 NRRaje Feb 06 Initiatives taken by State Govt. Various State Govts have taken initiatives for Jatropha Plantation notably Uttranchal Constituted “Uttranchal Bio-fuel Board” to promote Bio-fuel in the state 2 lakh ha.Jatropha plantation is proposed on degraded community land through Van Panchayat Chhattisgarh Chhattisgarh Bio-fuel Development Authority setup on Jan.2005 for development of bio-fuel in the state Govt. fallow land being offered to private entrepreneur. Action initiated to allot 70000 ha Land on lease to private entrepreneur NRRaje Feb 06 RESEARCH & DEVELOPMENT ‘National Network on Jatropha’ Objectives Selection of Superior planning material Standardization of Propagation techniques-Micro and Macro propagation. Standardizing agro- techniques Establishment of model plantation Tree improvement Detoxification of seed meal Development of pre-processing & processing equipments Imparting training to the farmers. NRRaje Feb 06 Issues for Investors Feed stock souring own /external source Long term contract Technology Appropriate for multi food stock Etraction of value added feed stock like phytochemical formulations during pre treatment Product quality Economic consumption of chemicals Domestic Export Glycerin quality & outlet Process plant size Transportation Infrastructure sharing NRRaje Feb 06 Key Factors of Production Feed stock cost Yield Conversion cost Product quality Bio-diesel sale price Glycerin sale price Energy cost Investment NRRaje Feb 06 Cost of Bio Diesel Production in India (As per Planning Com Report) Rate (Rs. Kg) Quantity(Kg) Cost (Rs.) Seed 5.00 3.28 16.40 Cost of collection & oil extraction 2.36 1.05 2.48 Less cake produced 1.00 2.23 -2.23 Trans- esterification cost 6.67 1.00 6.67 * Less cost of glycerol produced *40 to 60.00 0.095 -*3.8 to – 5.70 Cost of Bio- Diesel per Kg 19.52-17.62 Cost of Bio –Diesel per liter ( SP. Gravity 0.85) 16.59-14.98 * The price of glycerol is likely to be depressed with processing of such large quantities of oil and consequent production of glycerol. However , new applications are likely to be NRRaje Feb 06its price. found creating additional demand and stabilizing Comparative Economic Study Country Feedstock for Biodiesel Price of Processing Total Cost Feedstock Cost of biodiesel in $/MT in $/MT in $/MT 1 2 3=(1+2) USA Soybean Oil 560 500 1,060 Europe Rapeseed Oil 590 500 1,090 Sunflower Oil 565 500 1,065 India Jatropha Oil 770 250 1,020 Country Diesel Price Duty on net of duty Diesel Germany USA India $/MT 517 369 410 Diesel Price $/MT $/MT 588 1,104 166 535 250NRRaje Feb660 06 Total cost Subsidy given of biodiesel on biodiesel $/MT 1,065 1,060 1,020 $/MT 607 540 Issues of Seed / Oil Allocation Investors perspective Legislated for seed / oil allocation Price Policy on contract farming Feasibility / project report Covering all aspects of farming including yield guarantees. Farmers perspective Seed quality/ certification No certification available for non-edible oil seeds Management practices for Jatropha cultivation Crop behavior Holding pattern 11 million hectares 1crore farmers assuming 3,000 / hectare loan 3,000 crore required by farmers NRRaje Feb 06 Long Term Govt. Policies Long term plan for Energy Encourage production & usage of bio fuels Standards notification Directive /policy on procurement distribution & allocation of seeds / oils Firm Selling Price Policy on Excise & Sales Tax Encouraging Policy Customs duty Waiver on non-edible oils import & machinery initially NRRaje Feb 06 Thanks For Attention… NRRaje Feb 06