HIV Drug Resistance Training

advertisement

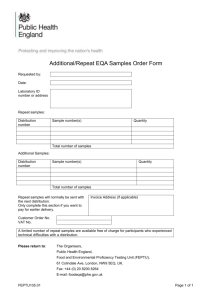

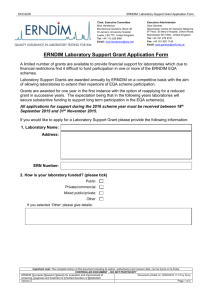

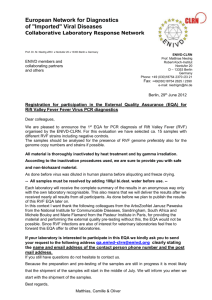

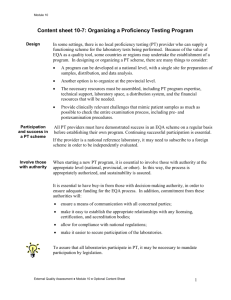

HIV Drug Resistance Training Module 11: Quality Control and Quality Assurance 1 Topics Quality Assurance vs. Quality Control Quality Assurance Before, During, and After Testing Quality Control EQA 2 Objectives Identify requirements for QC/QA. Identify types of quality controls that must be in place and the rationale for each. Given individual lab needs, develop a plan for setting up an internal QC program. Identify types of quality assurance programs and their purpose. Given individual lab needs, develop a plan for setting up an external QA program. 3 quality assurance vs. quality control What is the difference between QA and QC? 4 Terms Quality Control Quality Assurance Quality Assessment 5 Definitions Term Definition Quality Control The measures that must be included during each assay to verify that the test is working properly. Quality Assurance The overall program that ensures that the final results reported by the laboratory are accurate Quality Assessment A means to determine the quality of the results generated by the laboratory. It is usually an external evaluation of the laboratory's performance. Quality assessment is a challenge to the effectiveness of the QA and QC programs. 6 Quality Assurance vs. Quality Control Quality Assurance Activities to ensure process are adequate for a system Definition to achieve its objectives Establish standard procedures for sample collection Define criteria for acceptable samples Examples Quality Control Activities to evaluate a product or work result Analyze known QC sample to determine if a test is valid Decide if a sample is acceptable for testing 7 Quality Control is Part of Quality Assurance Quality Assurance Quality Control "The aim of quality control is simply to ensure that the results generated by the test are correct. However, quality assurance is concerned with much more: that the right test is carried out on the right specimen, and that the right result and right interpretation is delivered to the right person at the right time.” 8 QA or QC? HIV-negative plasma control SOP writing Personnel records Phylogenetic analysis DBS condition inspection Instrument calibration Proficiency testing New operator training Assay validation Lot release testing 9 The Quality Assurance Cycle Sample collection Personnel competency testing Reporting Record keeping and data management • Data and Lab Management • Safety • Customer Service QA and QC Genotype testing Sample receipt and accessioning 10 Discussion What is the difference between QA and QC? 11 quality assurance before, during, and after testing What are some examples of errors that occur before, during, and after testing, and what can we do about them? 12 The Quality Assurance Cycle Sample collection Personnel competency testing Reporting Record keeping and data management • Data and Lab Management • Safety • Customer Service QA and QC Genotype testing Sample receipt and accessioning 13 Pretesting Sample collection Personnel competency testing Reporting Record keeping and data management • Data and Lab Management • Safety • Customer Service QA and QC Genotype testing Sample receipt and accessioning 14 Preventing and Detecting Errors Before Testing Lab personnel training and certification Sample criteria set and used Specimen labeling, collection and transport Specimen storage and processing Check storage and room temperature Lab set up Reagent inventory and expiration dates SOPs for all related procedures Preventive maintenance and equipment checks External Quality Assessment (proficiency testing) 15 During Testing Sample collection Personnel competency testing Reporting Record keeping and data management • Data and Lab Management • Safety • Customer Service QA and QC Genotype testing Sample receipt and accessioning 16 Preventing and Detecting Errors During Testing Conducting test according to SOPs Quality Control (QC) (in-process controls) Safety precautions Prepare reagents Correctly interpreting test results Time management and planning 17 Post-testing Sample collection Personnel competency testing Reporting Record keeping and data management • Data and Lab Management • Safety • Customer Service QA and QC Genotype testing Sample receipt and accessioning 18 Preventing and Detecting Errors After Testing Re-check patient/client identifier Write legibly Clean up and dispose of contaminated waste Complete quality control review – Positive and negative control results – Contamination check (phylogeny) – Other QA checking (e.g. SQUAT) Transcribing, reporting and interpreting results Critical review of results and interpretation Record Maintenance 19 SQUAT: Sequence Quality Assessment Tool QA tool developed for WHO by Dr. Rami Kantor and colleagues, Brown University Open-source and freely available To be used by genotyping labs before sending sequences to national HIVDR working groups for surveillance and monitoring activities – Labs should perform initial investigations and take corrective actions if required Sequences can be assessed by WHO for external quality assurance as part of ongoing accreditation process 20 SQUAT Functions Sequence alignment HIV PR and/or RT sequence identification Mutation identification and generation of export file for uploading to database Flagging of problematic sequences – – – – – – ambiguous bases (mixtures) stop codons insertions/deletions frameshifts genetic distance anomalies atypical and ambiguous amino acids 21 Quality Assurance is Everywhere! Sample collection Personnel competency testing Reporting Record keeping and data management • Data and Lab Management • Safety • Customer Service QA and QC Genotype testing Sample receipt and accessioning 22 Find It, Then Fix It Problem Corrective Action Use a problem-solving team. Investigate root causes. Develop and implement appropriate corrective actions. Examine effectiveness. Record all actions and findings. 23 Discussion Why do errors occur? What are some common errors that might occur with HIVDR Genotyping? Where is QA applied in a HIVDR testing site? What are some steps to take before, during, and after testing to assure the quality of results? Describe the impact that errors will have on public health. 24 Quality Control What do we need to do to set up a quality control program for our genotyping? 25 What is quality control (QC)? Monitoring the test quality itself Ensuring that the assay is working appropriately and accurate test results are reported with confidence. Prevention Detection Correction 26 QC: Two Levels/Two Types Levels – Testing of samples with known results to verify the procedure is working properly – Interpreting the presence or absence of controls. Types – Internal quality control – External quality control 27 Internal QC Internal QC samples with known reactivity are included with the following HIVDR test kits. – TruGene – ViroSeq For in-house assays, prepare and qualify your own internal QC samples Test the IQC samples as you would test patient specimens. Include positive and negative controls in every run. Know what to do in case of unexpected results 28 Genotyping Assay Procedures Patient virus RNA Extraction cDNA synthesis (RT) Positive and negative controls cDNA amplification (PCR) Sequencing reactions Positive control Electrophoresis Data Analysis (base calling) Report (sequence, mutations, interpretation) 29 Guidelines for HIVDR Genotyping Internal QC Policies Negative controls – HIV-negative plasma, at extraction step – Water, at RT step and at PCR step • If any negative control shows a detectable PCR product, all samples must be discarded – Investigate to locate source of contamination Positive controls – HIV-positive plasma, at extraction step – HIV DNA at PCR step (low copy number) • If positive control does not produce a PCR product, investigate to determine cause; handling of products from test samples may depend on outcome – HIV DNA at sequencing step SOPs required 30 External QC External QC samples do not come with the test kit and are provided by an external source – Regional reference laboratory – Commercial supplier – Another laboratory that has prepared validated quality control in-house samples Test the EQC samples as you would test patient specimens. 31 Internal or External Control Failure If QCs fail, repeat the run. If problems or errors occur, then corrective actions should be taken before results distribution. Problem Corrective Action 32 Planning Your Internal QC Program Incoming samples Incoming reagents and kits Methodology or instrument comparison 33 Incoming Samples Upon arrival, all incoming sample shipments should be evaluated for proper collection, transport and storage 34 Incoming Reagents and Kits Evaluate all incoming reagents and kits upon arrival. Perform lot-to-lot comparisons. – Assay previously tested patient samples or controls on both the previous lot and the new lot and compare the results. – When a new lot has been evaluated and ‘passed,’ label container “Ready to Use.” 35 Lot-to-lot Comparison for Critical Reagents Lot-to-lot comparison for critical reagents: – For commercial kits: • Perform parallel run with new vs. existing kits • Define acceptance criteria for reagent lot to lot comparison – For home-brew assays: • Perform parallel run with new vs. existing lots • New lot of primers, RT-PCR enzymes, sequencing reagents Source of specimens – Positive controls – Previously tested samples – Old proficiency panels 36 Critical Reagent Quality Control Extraction buffers Enzymes (RT, DNA polymerase) RNA Purification RT-PCR Primers Reaction buffers Sequencing reactions Capillary matrix polymer Electrophoresis Results 37 Methodology or Instrument Comparison For tests that have multiple instruments available in the laboratory for use, compare instruments. Results should be comparable. Compare and document results routinely (depending on lab throughput). = ? 38 Small Group Discussion 1. 2. 3. 4. 5. What do you need to do to set up a QC program for genotyping? What components should be included? If a RT-PCR negative control becomes positive, what should you do? How can you perform lot-to-lot comparisons in your lab ? What is critical to include in a QC SOP? Once you are done with a lot-to-lot comparison and obtained satisfactory results, what should you do for the next step? 39 EQA What is EQA and why is it important? Which EQA Methods should we employ? • Proficiency Testing • On-Site Evaluation • Re-testing 40 A Systems Approach to Laboratory Quality Organization Personnel Equipment Stock Management Quality Control Data Management SOP, Documents & Records Occurrence Management Assessment Process Improvement Specimen Management Safety & Waste Management 41 External Quality Assessment (EQA): Definition and Purpose Objective assessment of a test site’s operations and performance by an external agency or personnel Allows comparison of performance and results among different test labs Provides early warning for systematic problems associated with kits or operations Provides objective evidence of testing quality Indicates areas that need improvement Identifies training needs 42 Management Responsibilities Determine policies for EQA (WHO, WHAT, WHEN, HOW) Assign responsibility Establish & maintain a system and schedule Receive EQA results and support corrective action measures Manage corrective action efforts Monitor and maintain records Investigate deficiencies Communicate outcomes 43 Testing Personnel’s Responsibilities: Overview Participate in the EQA program Take corrective actions Maintain EQA records Communicate outcomes to supervisors 44 EQA Methods On-site Evaluation Retesting Proficiency Testing 45 What is Proficiency Testing? Panels of specimens are sent to multiple test labs by reference laboratory/EQA provider Test labs perform tests and report results Results indicate quality of personnel performance and test lab operations Results are often compared across several testing labs Proficiency Testing 46 Proficiency Panels for HIVDR EQA VQA (NIH-supported, Rush University, Chicago1) TAQAS (TREAT Asia2) ENVA/QCMD3 ANRS France DigitalPT/Accutest Acrometrix Others? 1. Huang et al. J Clin Microbiol.43(8):3963-70 Aug 2005 2. Land et al. Journal of Virological Methods 159(2): 185-193; Aug 2009 3. Pandit et al. J Clin Virol. 43(4): 401-6; Dec 2008 47 What is On-site Evaluation? On-site Evaluation Periodic site visits to perform systematic assessment of lab practices – Focuses on how the lab monitors its operations and ensures testing quality – Provides information for internal process improvement 48 What is On-site Evaluation? – Cont’d On-site Evaluation Also referred to as audits, assessments, or supervisory visits Learn “where we are” Part of every lab quality system Measures gaps or deficiency Collect information for: – Planning & implementation – Monitoring – Continuous improvement 49 What is Re-testing? The process by which a random selection of specimens are collected from the routine workload at the test lab and sent to the reference laboratory for validation Used to detect errors Retesting 50 EQA Should Lead to Corrective Actions EQA Identify problems Take corrective action 51 Sample of Corrective Action Form 52 Small Group Discussion What are the methods in a EQA program? What type of EQA is most appropriate in our own situation? 3. What is the potential of internal bias in selfevaluation of quality? 1. 2. 53 How To Implement EQA Proficiency testing Retesting On-site evaluation 54 On-Site Evaluation Process Preevaluation preparation Entrance interview Information gathering Outcome assessment Exit conference Reporting 55 On-Site Evaluation Checklist 56 Tester Responsibilities: Ensuring a Productive Site Visit Before Visit: – – – – Record keeping is essential. Get organized Confirm date of visit Review written policies and procedures Conduct internal assessment in preparation of site visit During Visit – Participate in visits – cooperate – Ask questions of site assessors After Visit – Take corrective actions, where necessary Remember – visits are instructive, not punitive 57 On-site Evaluation: Pre-Evaluation Preparation Assign Responsibility – Laboratory management – Quality Manager Use Integrated team approach Determine who will conduct on-site evaluations – Select auditors with necessary skills: • Attention to detail • Ability to communicate effectively • Diplomacy – Provide appropriate training Schedule site visits 58 On-site Evaluation: Pre-Evaluation Preparation Determine site visit frequency: – Established sites - twice per year/once per year For efficiency, cluster evaluations geographically Schedule in advance – Announced or unannounced visits 59 On-site Evaluation: Entrance Interview The entrance interview sets the tone for the entire visit Provide overview of process in terms of what will be done – – – – – – Review of facility Record review Observation Interview with testing staff Use of proficiency panel Exit interview 60 On-site Evaluation: Information Gathering Observe physical layout of the lab Evaluate testing operations – – – – – Specimen collection Observation of test performance Quality control Inventory of kits Record-keeping Use quality systems checklist Conduct in an instructional, not punitive, manner. 61 On-site Evaluation: Outcome Assessment YES Evidence of implementation & maintenance of quality system? • Conclude visit • No deficiencies NO • Ensure visit is sufficient to objectively document evidence • Expand visit or observation • Reference deficiencies 62 On-Site Evaluation: Exit Conference Review findings with supervisory and testing staff Make positive statements first – acknowledge staff cooperation and support Address negative findings – allow test site to discuss findings and provide additional information Provide instructions and timeframe for submitting plan for correcting problems 63 On-site Evaluation: Reporting Include information: – – – – – Lab Name & Location Date of Visit Assessment Team Members Major Findings Recommendations for corrective actions Submit completed checklist and report to relevant authorities 64 Minimal Package for QC/QA WHO-accredited DR labs should be enrolled in at least one EQA program Perform self-assessment at least once a year Internal/external controls must be included in each assay run and the results recorded. – Trending over time can be a very useful quality indicator Clearly define valid testing run criteria in related SOPs 65 Discussion What is EQA and why is it important? Which EQA Methods should we employ? – Proficiency Testing – On-Site Evaluation – Re-testing 66 Reflection What are our responsibilities in preventing, detecting, and correcting errors before, during, and after testing? 67 Summary Identify requirements for QC/QA. Identify types of quality controls that must be in place and the rationale for each. Given individual lab needs, develop a plan for setting up an internal QC program. Identify types of quality assurance programs and their purpose. Given individual lab needs, develop a plan for setting up an external QA program. 68