sourcing - University of Manitoba

advertisement

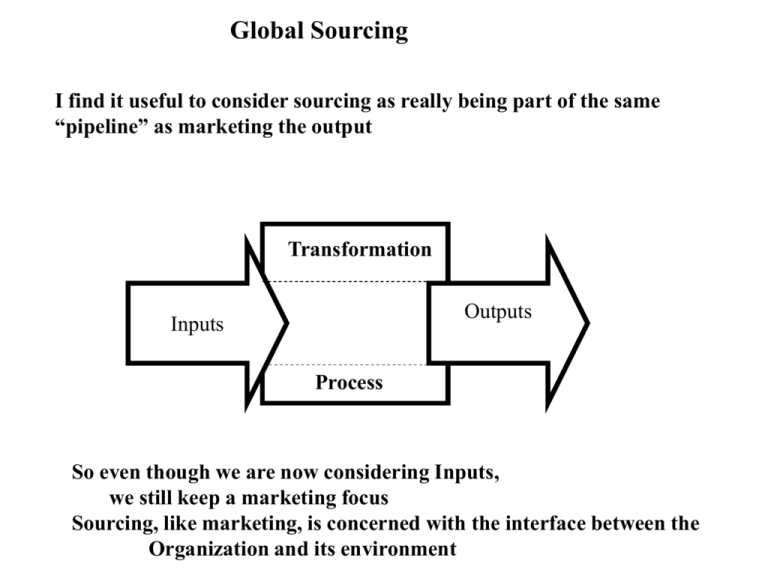

Global Sourcing I find it useful to consider sourcing as really being part of the same “pipeline” as marketing the output Transformation Outputs Inputs Process So even though we are now considering Inputs, we still keep a marketing focus Sourcing, like marketing, is concerned with the interface between the Organization and its environment Focus on Logistical management of R&D/manufacturing/marketing interface Growth Product Life Cycle Maturity applies internationally Decline Intro Optimum location may shift with change in the stage of the product life cycle Source of ideas Source of product Source of market - R&D - manufacturing - Marketing Must see them ALL working together to succeed R&D Marketing Manufacturing Advantage of globalization - locate each activity where it makes the most sense TV’s and Catscans are both examples of products which are technically inferior but which were successfully manufactured and marketed CAT invented by Emi (UK) but developed by GE (USA) TV’s - British held the original patents, but the Japanese designed around the circuits - more complex, but built it cheaper. Limitations on international product life cycle theory: 1. Faster product development, shorter innovation lead times reduces the advantage of polycentric approach 2. Predicting development of new/better sources during PLC gives shrewder companies an advantage. 3. Actively managing resource deployment on a global basis can give company pre-emptive first-mover advantage. Inherent conflict 1. Marketing dominated:Product modification to meet market differences at the expense of manufacturing efficiency 2. Production dominated:Excessive product standardization to meet production efficiency at the expense of satisfying market differentiation 3. R&D dominated: Over designed - too complex, too expensive, too much delay in time to market Trends in Sourcing Strategy 1. Decline in importance of X/C rate (i.e. not just price) 2. Effects of Excess Capacity - particularly in capital intensive “old economy” industries e.g. Steel, autos, newsprint, chemicals 3. Changes in International Trade Infrastructure (a) Growing management skill and expertise e.g; Row between GM & VW over new VP Purchasing (b) Transportation - Intermodal - containerization - scheduled liner services - air freight - costs have come down enormously - e.g. cheaper for me to air freight personal effects Bahrain- Winnipeg than send by sea/rail. - forwarders/ consolidators/brokers e.g. DHL, UPS, TNT Skypack, etc. now providing global coverage (c) Communication - fax, email, shipment tracing (d) New financing options - like countertrade. But old fashioned system of L/C’s still dominates . Perhaps, however, some shift to open 30-60-90 day lines of credit, as in domestic trade. (e) Multiplicity of sources, and shifts in source location - raw materials - grain, coal, iron ore, alumina, crude oil - components - I/c’s, chips, auto components - assembled goods - OEM’s, contract manufacture - regional aircraft - not US, Holland or UK but Canada and Brazil 4. Enhanced role of purchasing manager - role of purchasing and logistics starting to come out of the shadows 5. Trend to Global Manufacturing Old style - manufacture at home, export everywhere New style - manufacture everywhere, sell everywhere - Two trends - (a) setup complete assembly factories in foreign markets (b) setup factories to build key components in particular place and supply all factories from there, e.g. Ford engine plants. Potential Pitfalls of Global Sourcing Unresolved tension in global manufacturing Standardization Financial Pressure Local Market Differentiation Political pressure nationalism Modern globalization - willingness to face this dilemma and get a balanced answer Partly being forced by competition - many multi-nationals out there as well as local firms - “if we don’t, someone else will” Note criticism of US companies over last several decades- management thinking dominated by marketing and finance/accounting - inadequate consideration of production factors. - Criticism also applies equally to a lot of UK and European companies as well Offsetting this, however, we must acknowledge the tremendous gains in productivity in the US economy during the 1990’s - and you can’t do that by ignoring manufacturing! Another factor which arises repeatedly in international case studies, is the tendency for parent companies, particularly American ones, to force home office systems and procedures on subsidiaries, whether they fit or not - planning - budgeting - reporting (including converting accounts to US$) - decision making - organization structure - patterns of HR - etc. Concept of the Value Chain: Sequence of all activities from product design, resource acquisition through inbound logistics, manufacturing and assembly, promotion, sales, distribution, and after-sales service which adds value to the final product in the hands of the customer; Together with support activities such as - human resource mgt, - technology development - accounting/IT Elements of the Value Chain Planning, Finance, MIS , Legal Technology, R & D, Design Product design Purchasing, ProducRaw Mat’l tion Handling Marketing, Distribution Customer Channels Service, Sales Advertising Warehouse M’tce & Delivery Repair Human Resource Management Steps in value chain analysis: 1. Identify the separable links in the company’s value chain 2. For each link, do we have any competitive advantage - either scale or scope? 3. What are the transaction costs between links? - negotiation - monitoring - uncertainty/risk - economic? political? 4. Determine the comparative advantage of countries/locations relative to - each link of the value chain - associated transaction costs 5. Build in sufficient flexibility to cope with changes in - competitive advantage of the company - comparative advantage of the country Managing R&D - Manufacturing Interface -Focus on both Process technology and Product technology Product technology examples - EMI / GE CAT scan - TV’s - Xerox - Polaroid Process technology - Canon over Xerox - photocopier - Boeing over BAe - jet aircraft - Pfizer and penicillin - Rolls Royce still competitive in jet enginesNote too that Production can influence R&D by defining problems areas or issues that need improvement or a new solsution Ways of Managing Production / Marketing Interface 1. Standardize core components e.g. auto engines, transmissions computer memory chips, hard drives 2. Group products into product design families to gain some economies of scale e.g. auto industry base models (“platforms”) 3. Universal product with all features - either all standard or as selectable options e.g. Canon cameras 4. Universal product but different positioning, i.e target different market segments in different countries Tradeoffs: Standardization Diversification Long prod’n runs Produce to order Cost Quality Marketing - R&D Interface Problem is trying to maximize satisfaction of consumers needs and wants While at the same time trying to maximize what is technically possible. Management problem: Deciding when to “freeze” development and go into production One possible answer: continuous product development - staged improvements to basic product. Problem - overtaken by a “blockbuster” novelty (fashion trade particularly vulnerable) - lose out to fundamental shift in character of product, so that our standard product suddenly finds itself obsolete. Fundamental issue: monitoring trends keeping response time and development times short Logistics of Sourcing Intra-firm vs. Vertical integration But - Higher mgt complexity - Slow response time Outsourcing We focus on core competencies But - lose contact with technology design manufacturing skills Which way to go ? One solution: strategic alliances -separate as in outsourcing - blended as in integrated Problem: Who’s in charge?? Dominant partner? Equal partners ? (but some of us are more equal than others!)