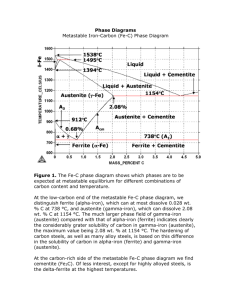

Fe-C Phase Diagram

advertisement

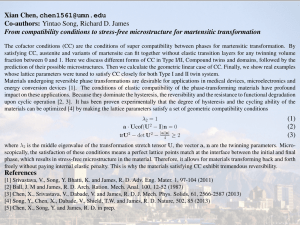

3.40/22.71 Summary of 11/29/2012 Sergio Castellanos Mechanical Engineering Department Massachusetts Institute of Technology, Cambridge, MA (USA) Fe-C Phase Diagram δ (Ferrite) Liquid BCC 1394 ºC γ+Liquid Solid 1130 ºC 2.11% γ (Austenite) FCC γ+Cementite 912 ºC α+γ α (ferrite) 0 Not to scale 0.022% α+Cementite Carbon (% by Weight) Cementite (Fe3C) 723 ºC 6.67 Martensite Transformation Austenite Martensite x x Large Cooling Rate dT dt BCT* FCC Scalar Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid. ISBN 0-13-148965-8. © 2006 Vectorial (BCC) Martensite Transformation Displacive: C diffusion is restricted Bain Transformation: tr ε =~ 0 Constant Volume Twinning Strain (Simple Shear) [1] Lieberman, Acta Metallurgia 6 (1958) [2] H. Ledbetter, M.L. Dunn, Materials Science and Engineering A273-275 (1999) 222-225 Twinning plate w v1 (1 w) v 2 Energy: Least if formed into disk But all at once? ΔG Still incur in expense: Interface Energy Good thing: w proportions cancel strain fields Coherent TB Wechsler-Lieberman-Read (WLR) Theory A.L. Roitburd and G.V. Kurdjumov, Mater. Sci. & Eng, 39 (1979), 141. a Elastic Energy vs. Interfacial Energy ….. Steels: 10’s nm bi-layer Importance of Martensitic Transformation Utilization: total applied residual Tempering: Hardness (Rockwell) 200 ºC 600 ºC t Difussion process Cementite in Ferrite matrix Image credit: http://courses.washington.edu/mse170/labs/HeatTreatment/HeatTreatment_micrographs.shtml Shape-Memory Alloys Detwinning Cooling Heating/Recovery T Image Credits: [1] Texas A&M – Active Materials Laboratory [2] http://beckause.blogspot.com/2008/02/accordions-are-sexy.html Thank you Image credit: http://www.lassp.cornell.edu/sethna/Tweed/What_Are_Martensites.html Appendix Martensite-Austenite interface structure