Heat Treatment of Metals

advertisement

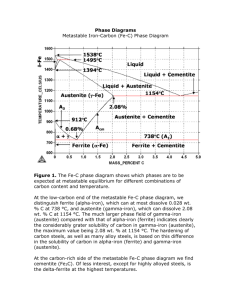

Heat Treatment Heating a metal or alloy to various definite temperatures, holding these for various time durations and cooling at various rates. Combination of controlled heating and cooling determine not only the nature and distribution of micro-constituents (which determine the properties of a metal or alloy), but also the grain size. Contd... Purpose of heat treatment: 1.To remove or relieve strains or stresses induced by cold working or non-uniform cooling (for example welding): Annealing 2. To increase strength or hardness of the material for improved wear resistance: Hardening 3.To improve machinability: Annealing 4.To soften the material: Annealing 5. To decrease hardness and increase ductility and toughness. (Tempering) Contd... 6. To improve the cutting properties of tools. 7. To change or modify the physical properties of the material such as electrical properties, magnetic properties, corrosion resistance and heat resistance etc. Main Processes Include Annealing Full Annealing Isothermal Annealing Process Annealing Spheroidisation Normalizing Hardening and Quenching Tempering Contd... Annealing processes Annealing is a heat treatment process in which the material is taken to a high temp. kept there for some time and then cooled in furnace. Cooling is done slowly to avoid the distortion. Contd... Benefits of annealing are: • relieve stresses • increase softness, ductility and toughness • produce a specific microstructure • modify electrical and magnetic properties Depending on the specific purpose, annealing is classified into various types: process annealing, stress relief, full annealing and normalizing. Full annealing This consists of heating the steel to a temperature above the transformation range, holding for one two hours and then cooling at a predetermined rate to obtain the desired microstructure. Grain refinement is accomplished in this instance by the recrystallisation of the steel in passing through the critical range in both heating and in cooling. Isothermal annealing It is a type of full annealing in which the steel first is cooled to the temperature at which it is desired to have transformation occur, at a rate sufficiently rapid to prevent any structural change above the temperature. The steel then is held at the selected temperature for the time necessary to complete such transformation. Process annealing This consists of heating the steel to a temperature first under lower critical point and holding at this temperature for the proper time(usually 2 to 4 hours) followed by air cooling Contd... Spheroidisation This is accomplished by heating to a temperature just above the critical point and cool very slowly through the critical range. This treatment is used for practically all steels containing over 0.6% carbon that are to be machined or cold formed. Contd... Normalizing Main objective 1. Refine grain, improve machinability, tensile strength and structure of weld. 2. Remove cold worked stess. 3. Remove dislocations due to hot working. Process Heat the steel approximately 4°C above its upper critical temp, held about fifteen minutes and then allowed to cool down in still air. Homogeneous structure provides a higher yield point, ultimate tensile strength and impact strength with lower ductility to steels. Contd... Hardening and Quenching Hardening is a process in which steel is heated to a temperature above the critical point, held at this temperature and Quenched (rapidly cooled) in water, oil or molten baths. If a piece of steel is heated above its upper critical temperature and plunged into water to cool it an extrewmely hard, needle-shaped structure known as martensite is formed. In other words, sudden quenching of steel greatly increases its hardness. Tempering Martensite structures formed by direct quenching of high carbon steel are hard and strong, but unfortunately are also brittle. They cannot be plastically deformed and have very little toughness, and although strong are unable to resist impact loads and are extremely sensitive to stress concentrations. Some of the hardness and strength must be sacrificed to obtain suitable ductility and toughness. This is done by tempering the martensic steel. Tempering Objective of Tempering are: Increase toughness Decrease hardness Stabilise structure Relieve stresses The process of Tempering consists of heating Quenched, hardened steel to some pre determined temperature between room temperature and the critical temperature of the steel for a certain length of time, followed by air cooling. Fe-C equilibrium diagram The structural form of pure iron at room temperature is called ferrite or -iron. Ferrite is soft and ductile. Since ferrite has a body-centred cubic structure, the inter-atomic spaces are small and pronouncedly oblate, and cannot readily accommodate even a small carbon atom. Therefore, solubility of carbon in ferrite is very low, of the order of 0.006% at room temperature. The maximum carbon content in ferrite is 0.05% at 723 °C. Contd… The face-centred modification of iron is called austenite or -iron. It is the stable form of pure iron at temperatures between 910°C and 1400°C. At its stable temperature austenite is soft and ductile and consequently, is well suited for manufacturing processes. Contd… The maximum solubility is only 2% of carbon at 11 30°C. Above 1400°C, austenite is no longer the most stable form of iron, and the crystal structure changes back to a body-centred cubic phase called delta iron. This is -iron except for its the same phase as the temperature range. The solubility of carbon in -ferrite is small, but it is appreciably larger than In -ferrite, because of higher temperature. The maximum solubility of carbon in &iron is 0.1% at 1490°C. Contd… In the reaction, the simultaneous formation of ferrite and cementite from austenite results at the temperature of 723°C and composition of 0.80% carbon. Since the ferrite and cementite are formed simultaneously, they are intimately mixed. Characteristically, the mixture is lamellar, i.e., it is composed of alternate layers of ferrite and cementite. This micro-structure is called pearlite which is very important in iron and steel technology, because it can be formed in almost all steels by means of suitable heat treatments. Contd… The alloy containing 0.80% of carbon is called the eutectoid steel. Upon cooling the eutectoid steel below 723°C, all of the austenite is transformed into pearlite. Alloys with less than 0.80% C are called hypo- eutectoid steels and those with higher composition are called hyper-eutectoid steels. Contd… Fe-Fe3C phase diagram is characterized by five individual phases,: α–ferrite (BCC) Fe-C solid solution, γ-austenite (FCC) Fe-C solid solution, δ-ferrite (BCC) Fe-C solid solution, Fe3C (iron carbide) or cementite - an inter-metallic compound and liquid Fe-C solution and four invariant reactions: peritectic reaction at 1495 oC and 0.16%C, δ-ferrite + L↔ γ- iron (austenite) eutectic reaction at 1147 oC and 4.3 %C, L ↔ γ-iron + Fe3C (cementite) [ledeburite] eutectoid reaction at 723 oC and 0.8%C, γ-iron ↔ α– ferrite + Fe3C (cementite) [pearlite] Contd… Fig. TTT diagram for eutectoid transformation in Fe-C Fig. Transformations involving austenite for Fe-C system Bainite Formation Bainite is an intimate mixture of ferrite and cementite, as in pearlite. Pearlte has alternate layers of ferrite and cementite. In bainite however, cementite apparently exists as tiny spheroids uniformly distributed throughout a ferrite matrix. In upper bainite(formed at temperatures just below the nose of the TTT curve) there is evidence of some patterns in the cementite arrangement since the microstructure has a feathery appearance. In lower bainite(formed at temperatures approaching Ms) the cementite becomes too fine for resolution and an acicular(needle like) pattern is formed. Contd… Bainite is normally harder, stronger and tougher than fine pearlite of the same chemical composition(due to differences in size, cementite). shape and distribution of Contd… Martensite Formation The Martensite transformation occurs in a wide temperature range. It begins at a temperature corresponding to a point Ms(Martensite start). When the cooling process passes through the point Ms, austenite begins to transform into martensite. The lower the temperature, the more martensite will be formed. At a definite temperature for each steel, further transformation of austenite into martensite ceases. This temperature is usually denoted as Mf(Martensite finish) Contd… The positions of points Ms and Mf do not depend upon cooling rate and are determined by the chemical composition of austenite. More carbon in steel lowers points Ms and Mf. A characteristic feature of martensite formation is that it is practically never completed. Thus, a hardened steel contains retained autenite. The higher the carbon content the more austenite will be retained. The presence of retained austenite is undesirable as it has detrimental effect on its mechanical properties. The End