Heat Treatment

advertisement

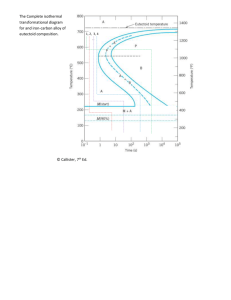

Annealing, Normalizing, and Quenching of Metals Manufacturing Lab Experiment # 1 Introduction • Heat Treatment: It is a method used to alter the physical and chemical properties of a material. Heat treatments are also used in the manufacture of many other materials, such as glass. It involves the use of heating, normally to extreme temperatures, to achieve a desired result such as hardening or softening of a material. Introduction (Cont.) • Heat treatment techniques include Annealing Case Hardening Precipitation Strengthening. Tempering Quenching. Case Hardening & Tempering • Case Hardening: is the process of hardening the surface of a metal, often a low carbon steel, by infusing elements into the material's surface, forming a thin layer of a harder alloy. • Tempering is done to "toughen" the metal by transforming brittle martensite into bainite or a combination of ferrite and cementite. Precipitation hardening • It is also called age hardening or dispersion hardening, is a technique used to increase the yield strength of materials, including most structural alloys of aluminum, magnesium, nickel and titanium, and some stainless steels. • It relies on changes in solid solubility with temperature to produce fine particles of an impurity phase, which impede the movement of dislocations, or defects in a crystal’s lattice. Annealing • It is a heat treatment process in which a material is exposed to an elevated temperature for an extended time period and then slowly coold. • In annealing the grain size obtained is coarser than that of normalizing & thereby annealing adds to the ductility of the steel. Why Annealing? • Annealing is carried out to: Relieve Stress Increase softness, ductility and toughness Produce a specific microstructure Annealing Stages • Annealing consists of three stages: Heating to the desired temperature Holding at that temperature Cooling to room temperature Normalizing • Normalizing is an annealing heat treatment process used to refine the grains (decrease the avg. grain size). • Produce a more uniform and desirable size distribution, fine grained particles Phase Diagram • • • • Ferrite Austenite Pearlite (Perlite) Cementite Ferrite • Ferrite Known as α-iron Pure iron at room temperature Body-centered cubic structure BCC. Austenite • Austenite Known as γ-iron 910°C Face-centered cubic FCC. Much softer than ferrite More easily worked Pearlite • Pearlite (Perlite) Pearly luster in the microscope Interference of light in its regular layers Most common constituent of steel Gives steel most of its strength “layered mixture of ferrite and cementite of average composition 0.83% carbon” Cementite • Cementite Hard, brittle, white melts at 1837°C density of 7.4 g/cc On the phase diagram, cementite corresponds to a vertical line at 6.7% C Engineers only care about compounds with less carbon Materials • A stock bar of low alloy steel AISI 4340. • It has the carbon content of about 0.4%, but the second contains other alloying elements such as molybdenum, nickel, and chromium. Review Questions • What is the effect of increasing the cooling rate (from furnace cooling to air cooling) on the fineness of pearlite formed and on the amounts of the different phases of the AISI 1040 specimens and AISI 4340 specimens? • What is the effect of increasing the cooling rate (from furnace cooling to air cooling) on the hardness of the AISI 1040 specimens and AISI 4340 specimens? Review Questions (Cont.) • Explain why it is very difficult to determine the carbon content of a normalized steel specimen from its microstructure only? • Estimate the amount of pearlite in each specimen and compare these amounts with the equilibrium values obtained from the iron carbon phase diagram. Review Questions (Cont.) • Mention some factors that may affect the actual cooling rate of an air cooled specimen. • What effects do the alloying additives have on the microstructure and mechanical properties of air cooled (normalized) steel specimens? • What effects do the alloying additives have on the microstructure and mechanical properties of furnace cooled (annealed) steel specimens?