table of contents

advertisement

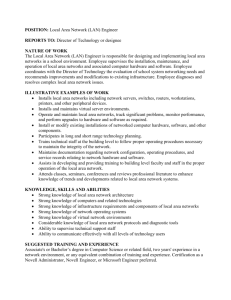

COMPUTER AIDED DESIGN OF SHEET METAL DIE ASSEMBLY UTILISING PRO | ENGINEER AND MECHANICA Vamshikrishna Reddy Chada B.Tech. Jawaharlal Nehru Technological University, India, 2007 PROJECT Submitted in partial satisfaction of The requirements for the degree of MASTER OF SCIENCE in MECHANICAL ENGINEERING at CALIFORNIA STATE UNIVERSITY, SACRAMENTO FALL 2010 COMPUTER AIDED DESIGN OF SHEET METAL DIE ASSEMBLY UTILISING PRO | ENGINEER AND MECHANICA A Project by Vamshikrishna Reddy Chada Approved by: ________________________________, Committee Chair Dr.Yong S.Suh _________________________ Date ii Student: Vamshikrishna Reddy Chada I certify that these students have met the requirements for format contained in the University format manual, and that this project is suitable for shelving in the Library and credit is to be awarded for the project. ________________________, Graduate Coordinator Dr.Kenneth Sprott Department of Mechanical Engineering iii _____________________ Date Abstract of COMPUTER AIDED DESIGN OF SHEET METAL DIE ASSEMBLY UTILISING PRO | ENGINEER AND MECHANICA by Vamshikrishna Reddy Chada In recent years the development of more and more products has become a remarkable trend in the automotive industry.The consumer demand for great variety and increasing environmental concenrs are forcing manufacturers to improve product development efficency encouraging the new desings in sheet metal die casting.The Pro Engineering and Pro Engineering Mechancia is a widely applied tools for designing models and for solving structural problems respectively.The punch,die and blankholder are three main parts in this sheet metal die casting and these can be representedy by finite element models,the die structure deflections and stress induced by loading condition can be predicted and can be designed according to requirements.The role of the blank holder in the generation of the restraining forces acting on the metal sheet is considered on top most point.The known fact is the choice of restraining force distribution is a key point in designing the sheet metal die.The factors that affect the actual restraining force distribution are briefly analyzed,identifying control factors.This capability allows achieving some actual advantages, considering that the technological development will iv supplies the engineers with hardware and software instruments able to analyze in short time large problems.The Finite element analyis allows to foresee possible inconveniences which could occur during the consturction by using only virtual models,before physical model being made. ________________________________, Committee Chair Dr.Yong S.Suh ______________________ Date v ACKNOWLEDGMENTS While working on this project, some people helped me to reach where I am today and I would like to thank all for their support and patience. Firstly, I would like to thank Professor Dr. Yong S.Suh for giving me an opportunity to do this project. His continuous support was the main thing that helped me to develop immense interest on the project that led to designing of punch and die assembly with emerging technologies. Dr.Yong S.Suh helped me by providing many sources of information that needed from beginning of the project till the end. He was always there to meet, talk and answer the questions that came across during the project. Special thanks to my advisor Dr Kenneth Sprott for helping me to complete the writing of this dissertation, without his encouragement and constant guidance I could not have finished this report. Finally, I would also like to thank all my family, friends and Mechanical engineering department who helped me to complete this project work successfully. Without any of the above-mentioned people the project would not have come out the way it did. Thank you all. vi TABLE OF CONTENTS Page Acknowledgments...................................................................................................... VI List of Figures ............................................................................................................. XI Chapter 1. INTRODUCTION AND BACKGROUND ..............................................................1 1.1) Introduction ............................................................................................................1 1.2) Foundry Casting .................................................................................................... 2 1.3) Specifications......................................................................................................... 3 1.3.1) Upper Die ............................................................................................... 3 1.3.2) Blank Holder........................................................................................... 4 1.3.3) Lower Die Punch .................................................................................... 4 1.4) Diagrammatic View of Model ............................................................................... 5 1.5) Working Principle...................................................................................................6 1.6) Problem Description .............................................................................................. 7 1.7) Tools used for Modeling and FEA ........................................................................ 8 1.7.1) Pro/ENGINEER .................................................................................... 8 1.7.2) MECHANICA ....................................................................................... 8 vii Chapter 2. DESIGN USING Pro/ENGINEER ........................................................................ 10 2.1) Introduction ......................................................................................................... 10 2.2) General Terms ..................................................................................................... 11 2.3) Geometric Terms ................................................................................................. 12 2.4) Pro/ENGINEER Versions ................................................................................... 13 2.5) Design of Sheet Metal Die Parts.......................................................................... 14 2.5.1) Design of Upper Die ............................................................................ 14 2.5.2) Design of Blank Holder ....................................................................... 15 2.5.3) Design of Lower Die Punch ................................................................. 16 2.5.4) Design of Pattern Surface Part.............................................................. 17 2.5.5) Design of Upper Die Surface Part ........................................................ 18 2.6) Design of Sheet Metal Die Assembly ................................................................. 19 2.6.1) Assembling Upper Die and Upper Die Surface.................................... 19 2.6.2) Assembling Lower Die and Pattern Surface......................................... 20 2.6.3) Die Assembly ....................................................................................... 21 2.7) Sheet Metal Die Exploded View ......................................................................... 22 Chapter 3. FEA ANALYSIS USING MECHANICA ............................................................. 23 3.1) Introduction ......................................................................................................... 23 viii 3.2) Problems Solved Using MECHANICA .............................................................. 23 3.3) Steps in Preparing an FEA Model ....................................................................... 24 3.4) Setting Up the Model in MECHANICA ............................................................. 26 3.4.1) Running MECHANICA ....................................................................... 26 3.4.2) Material Specification........................................................................... 27 3.4.3) Applying the Pressure Load ................................................................. 29 3.4.4) Defining Displacement Constraints ..................................................... 30 3.4.5) Defining Planar Constraint................................................................... 31 3.4.6) Running Basic Static Analysis ............................................................. 32 3.4.7) Running Auto Gem ............................................................................... 34 3.4.8) MECHANICA Convergency.................................................................35 3.4.8) Setting up Optimum Design Study ....................................................... 46 Chapter 4. RESULTS ................................................................................................................48 4.1) Results from Basic Static Analysis .......................................................................48 4.2) Results from Optimum Design Study Analysis ................................................... 48 4.3) Basic Static Vs Optimization-Deflections ............................................................49 4.4) Basic Static Vs Optimization-Stresses ................................................................ 50 4.5) Basic Static Vs Optimization-Principal Strain .................................................... 52 4.6) Dimensional Changes in Die Assembly ...............................................................54 ix 4.7) Graphical Results ................................................................................................. 55 4.8) Optimized Auto Gem............................................................................................57 CHAPTER 4. FEATURE WORK .................................................................................................58 References ...................................................................................................................59 x LIST OF FIGURES 1. Figure 1.4-1 Sheet Metal Die Assembly........................................ 2. Figure 2.5-1 Upper Die............................................................. 14 3. Figure 2.5-2 Blank Holder........................................................ 15 4. Figure 2.5-3 Lower Die Punch.................................................. 16 5. Figure 2.5-4 Pattern Surface..................................................... 17 6. Figure 2.5-5 Upper Die Surface Part........................................ 18 7. Figure 2.6-1 Upper Die Assembly............................................. 19 8. Figure 2.6-2 Lower Die Assembly............................................ 20 9. Figure 2.6-3 Die Assembly........................................................ 21 10. Figure 2.7-1 Exploded View..................................................... 22 11. Figure 3.3-1 Steps for FEA...................................................... 25 12. Figure 3.4-1 Model Setup......................................................... 26 13. Figure 3.4-2 Material Definition................................................. 27 14. Figure 3.4-3 Assigning Material................................................. 28 15. Figure 3.4-4 Assigning Load..................................................... 29 16. Figure 3.4-5 Assigning Displacement Constraint........................ 30 17. Figure 3.4-6 Assigning Planar Constraint................................... 31 18. Figure 3.4-7 Setting up Basic Analysis....................................... 32 xi 5 19. Figure 3.4-8 Running Basic Analysis.......................................... 33 20. Figure 3.4-9 Running Auto Gem................................................. 34 21. Figure 3.4-10 Setting up Convergence.......................................... 35 22. Figure 3.4-11 Running Multi-pass Adaptive Test........................... 36 23. Figure 3.4-12 Setting Up Optimum Design Study.......................... 46 24. Figure 3.4-13 Running Optimum Design Study............................ 47 25. Figure 4.3-1 Deflections in Fringe Display Type.......................... 49 26. Figure 4.4-1 Stresses in Fringe Display Type.............................. 50 27. Figure 4.4-2 Maximum Stress Locations..................................... 51 28. Figure 4.5-1 Principal Strain in Fringe Display Type................... 52 29. Figure 4.5-2 Maximum Principal Strain Locations....................... 53 30. Figure 4.6-1 Dimensional Changes in Die Assembly................... 54 31. Figure 4.7-1 Graphical Area Considered..................................... 55 32. Figure 4.7-2 Deflections in Graphical Display Type..................... 56 33. Figure 4.8-1 Auto-Gem after Optimization................................... xii 57 1 Chapter 1 INTRODUCTION AND BACKGROUND 1.1) Introduction: In recent years the development of more and more cars with different external appearance has become a remarkable trend in the automotive industry. As another trend the increasing use of high and ultrahigh strength steel grades for bodies should be mentioned. Both trends generate higher costs for individual tools that are traditionally made as stiff as possible. Sheet Metal Dies, one of the tools used in making sheet metal parts for automobile industry account 35% of total cost of a vehicle program. The construction cost of these dies is used as benchmark by the automotive companies to evaluate the cost of any new vehicle program and also to determine where they stand compared to their competitions. These sheet metal dies are designed accordingly for a particular company based on the internal process, safety guidelines and press allocations. As these sheet metal dies are operated regularly and subjected to various load conditions in their lifecycle and hence the die should provide sufficient safety factor to prevent any structural failure of dies and also should compensate the elastic deformations or deflections. The die breakage during production can cause a complete halt of production which stops the production cycle in an industry. Due to this extreme importance of these dies to be safe during the entire production cycle the die design standards are made very traditional and dies thus made of heavy weight. Due to this heavy structure of the dies, the cost of raw material, 2 construction costs, operating costs are huge. But, now the availability of finite analysis can be performed on these dies for various line die operations and opportunities to explore savings in weight can be explored to reduce the structural and operating costs. The various safety measures can be analyzed by thorough finite element analysis and also root cause of the breakage problems can be fixed in a more efficient manner. The two key requirements of tool design are meeting functional performances and achieving greater manufacturing reliability. There are number of important areas of the die that can be standardized and helps to reduce the manufacturing cost and production time. This applies more intended to pattern making activities that are time consuming, expensive and more human errors. 1.2) FOUNDRY CASTING: The old fashioned and manual approach to foundry pattern making has number of drawbacks like Dimensional accuracy cannot be assured Manufacturing times are too long Excess material on critical areas of the casting can result in poor quality and a weaker casting Poor quality pattern joints are a potential source of casting weakness and thus compromise safety. 3 The above errors can be overcome by using standard pieces and NC machining of working surfaces, but designing the automated sheet metal casting dies are more helpful compared to this old fashioned pattern making. 1.3) SPECIFICATIONS: The sheet metal die assembly mainly consists of three parts. They are 1.3.1) UPPER DIE: Upper die is the upper portion of a die set that corresponds with the lower die via blank holder and move down onto the work piece. Upper die is of rectangular shape with hallowing centered area. All the four side of the upper die is composed of rectangular ribs which make the force applied to be distributed evenly. The upper area of the die is divided with uniform rectangular ribs which are useful to place press slider firmly. The bottom part of the die consists of ten equally dimensioned pins which lie on blank holder pins. The dimensions of the upper die and material specifications are as follows. Length = 1650 mm Width = 1170 mm Height = 485 mm Upper ribs = 230 * 200 mm Side ribs = 460 * 200 mm Material Used = High strength Steel Density of Steel = 7.82708e-09 ton/mm^3 4 Poisson’s ratio = 0.27 Young’s Modula’s = 19.98 Mpa 1.3.2) BLANK HOLDER: The Blank holder is used to prevent the edge of a sheet metal blank from wrinkling during deep drawing operations. Blank holder is of rectangular in shape with rectangular ribs on bottom part. It has cushioned pins on the bottom which lie on punch die. The dimensions and material specification is as follows. Length = 1650 mm Width = 1215 mm Height = 220 mm Bottom ribs = 215 * 155 mm Material Used = High strength Steel Density of Steel = 7.82708e-09 ton/mm^3 Poisson’s ratio = 0.27 Young’s Modula’s = 19.98 Mpa. 1.3.3) LOWER DIE PUNCH: Punch die is bottom part of the die assembly. It is the fixed part in die assembly and it is firmly fixed at the bottom. Punch die is of rectangular in shape with rectangular ribs on bottom and on upper part a pattern model of required shape is firmly fixed. The dimensions and material specification is as follows. Length = 1650 mm 5 Width = 1215 mm Height = 160 mm Bottom ribs = 265 * 265 mm Material Used = High strength Steel Density of Steel = 7.82708e-09 ton/mm^3 Poisson’s ratio = 0.27 Young’s Modula’s = 19.98 Mpa. 1.4) DIAGRAMATIC VIEW OF MODEL: UPPERDIE PINS BLANKHOLDER LOWERDIE Figure 1.4-1: SHEET METAL DIE ASSEMBLY 6 1.5) WORKING PRINCIPLE: Sheet Metal die casting is one of the most advance technique used in automobile industry. This die casting assembly mainly consists of upper die, punch, blank holder, cushion pins, guided pins and press slider. The upper die is fixed to the press slider and punch is fixed to the ground. The blank holder, which is supported by the cushion pins, holds the blank sheet and controls the drawing between the upper die and the punch. The 1500 ton press/die has 900 tons of drawing force by the punch and 80 tons of blank holding force deliverable to the blank holder. The press slider transfers the drawing load to the upper die and the cushion pins delivers the holding load to the blank holder. The load is applied firmly until the upper die guided pins completely moves on to the blank holder pins and once when both pins contacts together the drawing load applied is gradually reduced. As the drawing process proceeds, the blank sheet in the blank holder gets the shape as the pattern on the punch. In order to count for the load differences transferred among upper die, punch and blank holder the contact boundary conditions i.e. the pins height both on upper die and blank holder must be adjusted accordingly. Then the blank sheet with required shape is removed and new sheet is loaded and the process will repeat again. 7 1.6) PROBLEM DESCRIPTION: Among the main components of sheet metal die, the role of blank holder in the generation of the restraining forces acting on the metal sheet during the deep drawing is considered. It is well known fact that the choice of restraining force distribution is a key point in designing the sheet metal die. These restraining forces are mainly controlled by the height and diameter of guided pins on upper die and blank holder. Due to the load of press slider, large deformations are caused and big stresses are concentrated in the upper die and blank holder. The evolution of the blank holder and upper die modeling in the finite element simulation of the drawing process is reviewed and the need of deformable model of the blank holder and upper die to obtain process realistic simulation is pointed out. The factors that affect the actual restraining force distribution are briefly analyzed and also identifying control factors like overall deformations of die. 8 1.7) TOOLS USED FOR MODELING AND FEA: 1.7.1) PRO/ENGINEER Pro/ENGINEER mechanical design software from Parametric Technology Corporation is used for creating 3D computer models of mechanical parts and assemblies and the creation of 2D drawings for the models. Like any software it is continually being developed to include new functionality. Its main aim is to outline the scope of capabilities to give an overview rather than giving specific details on the individual functionality of the product. Pro/Engineer is a piece of software that falls within the category of CAD/CAM/CAE and site alongside other similar products currently on the market. Pro/Engineer is a feature based modeling architecture incorporated into a single database philosophy with advanced rule based design capabilities. The capabilities of the product can be split into the three main heading of Engineering Design, Analysis and Manufacturing. This data is then documented in a standard 2D production drawing or the 3D drawing standard ASME Y14.41-2003. 1.7.2) MECHANICA Finite Element Analysis (FEA), also known as Finite Element Method (FEM), is one of the most important tools added to mechanical design engineer’s toolkit in recent years. Because of very powerful desktop workstations, FEA is now available at a practical cost to virtually all engineers and designers. 9 MECHANICA is one of the many commercial systems that are available. MECHANICA is an integrated option in Pro/ENGINEER and is actually composed of two programs which are structural and thermal. In present paper the structural MECHANICA analysis is used for analyzing the die assembly at several boundary conditions. 10 Chapter 2 DESIGN USING Pro | ENGINEER 2.1) INTRODUCTION: Pro | ENGINEER is one of the mechanical design software from Parametric Technology Corporation which include creating 3D computer models of mechanical parts and assemblies, and creation of 2D drawings for the models. This CAD software runs on Microsoft Windows and UNIX platforms. Like any other software it is continually being developed to include much new functionality. Pro/Engineer is a piece of software that falls within the category of CAD/CAM/CAE and site other similar products currently on the market. Pro/Engineer is a feature based modeling architecture incorporated into a single database philosophy with advanced rule based design capabilities. The capabilities of the product can be split into the three main heading of Engineering Design, Analysis and Manufacturing It is different from many other CAD tools by the following way. Pro/ENGINEER is a not a drafting system instead it is a three dimensional solid modeling system. The 3D solid model is the ‘engineering document of record’, not the drawing. It is not based on X, Y and Z axis system. Layers and colors are not related. Every time we save an object, it creates a new version of the object. 11 Before we use Pro/ENGINEER we need to know some of the terminology and concepts used. 2.2) GENERAL TERMS: a) Parametric: Parameters are modified to affect changes in the model. A dimension is a simple example of a parameter. b) Feature Based: It is a set of instructions that tells the system how to create geometry. Features are created in a logical order to convey design intent to the system. c) Modeling: Creating computer images coupled with geometric information defining a part or assembly. d) Model: It is the engineering document of record and contains all design information including dimension, tolerances, materials, notes, symbols, and manufacturing data. Models are two type’s i.e. part model and assembly model. e) Sketch: Part models are a collection of ‘sketched’ features. These sketches define geometric design intent as the model is created. f) Working Directory: It is the directory where all Pro/ENGINEER files are saved. 12 2.3) GEOMETRIC TERMS: a) Axis: It is the center of a cylinder or other revolved feature. It is used on drawings as centerlines and also to indicate symmetry on drawings. b) Blend: A feature that is created by blending from one shape to another. c) Datum Plane: It is the foundation of all models. These are non-solid, orthogonal, planar surfaces, and are used to create and orient the model’s solid geometry. It includes three default datum planes which are Top, Right and Front. d) Edge: It is intersection of two part surfaces. e) Extrude: It is used to create a sketch normal to a plane. f) Pattern: It is used to create a series of similar features. g) Plane: It is usually a flat object. Usually a datum plane but also can be a solid part face or surface. h) Point: It can be created on surfaces, at vertices, etc. i) Revolve: This feature is used to create revolving sketch about a centerline. j) Round: It is a fillet radius on a solid part. It can be constant or variable. k) Sweep: It is a feature created by a sketch that follows a path or trajectory. l) Vertex: It is intersection of three edges. 13 2.4) Pro/ENGINEER VERSIONS: Name/Version Build Number Date Pro/ENGINEER (Autofact1987premier) R1.01 1987 Pro/ENGINEER R 8.0 1991 Pro/ENGINEER R 9.0 1992 Pro/ENGINEER R 10.0 1993 Pro/ENGINEER R 11.0 1993 Pro/ENGINEER R 12.0 1993 Pro/ENGINEER R 13.0 1994 Pro/ENGINEER R 14.0 1994 Pro/ENGINEER R 15.0 1995 Pro/ENGINEER R 16.0 1996 Pro/ENGINEER R 17.0 1997 Pro/ENGINEER R 18.0 1997 Pro/ENGINEER R 19.0 1998 Pro/ENGINEER R 20.0 1998 Pro/ENGINEER R 2000i 1999 Pro/ENGINEER R 2000i2 Pro/ENGINEER R 2001 2001 Pro/ENGINEER Wildfire R 1.0 2002 Pro/ENGINEER Wildfire R 2.0 2004 Pro/ENGINEER Wildfire R 3.0 2006 Pro/ENGINEER Wildfire R 4.0 2008 Pro/ENGINEER Wildfire R 5.0 2009 Creo Elements/Pro R 5.0 (as of M065) 2010 The version used in this paper is Pro/ENGINEER Wildfire 3.0 2006. 2000 14 2.5) DESIGN OF SHEET METAL DIE PARTS: 2.5.1) DESIGN OF UPPER DIE: In order to design this in pro/ENGINEER feature used are Extrusion, sketch and planes. Figure 2.5-1: UPPER DIE 15 2.5.2) DESIGN OF BLANK HOLDER: In order to design this in Pro/ENGINEER features used are Extrusion, Points, Sketch, Style and Solidify. Figure 2.5-2: BLANK HOLDER 16 2.5.3) DESIGN OF LOWER DIE PUNCH: In order to design this in pro/ENGINEER features used are Extrusion, Pattern, Hole and Chamfer. Figure 2.5-3: LOWER DIE PUNCH 17 2.5.4) DESIGN OF PATTERN SURFACE PART: In order to design this in Pro/ENGINEER an important special feature is used. It is drawn by following reverse engineering principle i.e. import feature. It is imported from other CAD software. Figure 2.5-4: PATTERN SURFACE 18 2.5.5) DESIGN OF UPPER DIE SURFACE PART: In order to design this in Pro/ENGINEER an important special feature is used. It is drawn by following reverse engineering principle i.e. import feature. It is imported from other CAD software Figure 2.5-5: UPPER DIE SURFACE PART 19 2.6 DESIGN OF SHEET METAL DIE ASSEMBLY: In order to create the assembly of sheet metal die, initially we have to assembly the upper die and upper die surface parts and lower die and pattern surface. Hence it is assembled in the following way. 2.6.1) ASSEMBLING UPPER DIE AND UPPER DIE SURFACE: In order to assemble these two parts in pro / ENGINEER the assembly features like Mate and Align are used. Figure 2.6-1: UPPER DIE ASSEMBLY 20 2.6.2) ASSEMBLING LOWER DIE AND PATTERN SURFACE: In order to assemble these two parts in pro / ENGINEER the assembly features like Mate and Align are used. Figure 2.6-2: LOWER DIE ASSEMBLY 21 2.6.3) DIE ASSEMBLY: Now from the models which we have i.e. Upper die assembly, Lower die assembly and Blank holder the final die assembly is made. Lower die is kept in bottom position and upon that Blank holder is perfectly aligned and on the blank holder Upper die assembly is made to align perfectly so that the final assembly is made. Figure 2.6-3: DIE ASSEMBLY 22 2.7) SHEET METAL DIE EXPLODED VIEW: Pro / ENGINEER is a perfect tool where we can see the all parts in exploded view and also we come to know which parts are aligned or mate together. Figure 2.7-1: EXPLODED VIEW 23 Chapter 3 FEA ANALYSIS USING MECHANICA 3.1 INTRODUCTION: MECHANICA is one of the integrated Finite Element Analysis tool in Pro/ENGINEER. This software is one of the many commercial systems that are available. Mechanica is one of the unique Finite Element Analysis tool in many ways. When operating in integrated mode with Pro/ENGINEER, MECHANICA is actually composed of two programs i.e. Structure and Thermal. Structural analysis is used for linear static stress analysis, modal analysis, buckling analysis and large deformation analysis (nonlinear).Thermal analysis is used for steady state and transient thermal analysis. In present paper the structural analysis is used for sheet metal die assembly. 3.2 PROBLEMS SOLVED USING MECHANICA: The problems that are solved by using structure analysis are simple analysis, a parametric study called a sensitivity analysis, and a design optimization. a) ANALYSIS: A model is defined by some geometry by using Pro/ENGINEER and this model is transferred into MECHANICA. The material properties are specified, loads and constraints are applied, and one of several different types of analysis can be run on the model. b) SENSITIVITY STUDY: If we need to find out the overall effect on the solution by varying one or more design parameters, MECHANICA is the perfect tool for this case. We can do this by performing a number of similar analyses, and 24 changing the geometry of the model between each analysis. It has an automated routine which allows specifying the parameter to be varied, and the overall range. Then it automatically performs all the modifications to the model and calculates results for the intermediate values of the design parameters. c) DESIGN OPTIMIZATION: For a model by designating some design variables from some geometric parameters, we can make MECHANICA to find the combination of values of the design variables that will minimize some objective function like total mass, some design constraints like maximum stress or deflections etc and will find the optimum set of design variables automatically. 3.3 STEPS IN PREPARING AN FEA MODEL: After importing the model into MECHANICA, there are several steps to be followed in order to get perfect solutions. The steps are as follows. Recognize the model type Specifying the material properties, applied loads and model constraints Running Auto Gem to produce finite element mesh Solving the linear equations using solver Compute items of interest from the solution variables Display the results both graphically and Fringe mode. The overall procedure can be explained by the following figure. 25 CREATE GEOMETRY USING Pro/E MODEL TYPE SIMULATION PARAMETERS -MATERIAL PROPERTIES -MODEL CONSTRAINTS -APPLIED LOADS RUNNING FINITE ELEMENT MESH-AUTOGEM SOLVING LINEAR EQUATIONS COMPUTE/DISPLAY RESULTS OF INTEREST REVIEW Figure 3.3-1: STEPS FOR FEA 26 3.4) SETTING UP THE MODEL IN MECHANICA: After drawing the model in Pro/ENGINEER we are ready to launch the MECHANICA. 3.4.1) RUNNING MECHANICA: Mechanica is an integrated tool in Pro/ENGINEER. In order to run Mechanica, from pull down menu go to Applications and then Mechanica. It pops up a window saying the units which are used by the pro/ENGINEER. Then a window pops up which ask us to select model type and the analysis type. So, select solid as model type and structural analysis for analysis type. Figure 3.4-1: MODEL SETUP 27 3.4.2) MATERIAL SPECIFICATION: Now, we have to assign the material to the parts of sheet metal die assembly. It is a two-step process i.e. material definition and assigning it to the part. So, in present paper the defined material is steel and it is assigned to all parts i.e. for Upper die, Blank holder and Lower die. The following figures show the defining material and assign materials respectively. Figure 3.4-2: MATERIAL DEFINITION 28 Figure 3.4-3: ASSIGNING MATERIAL 29 3.4.3) APPLYING THE PRESSURE LOAD: Now a pressure load of 1000 lbm/in sec^2 is uniformly applied on the upper die. Now the model will appear similar to following figure. Figure 3.4-4: ASSIGNING LOAD 30 3.4.4) DEFINING DISPLACEMENT CONSTRAINTS: The Lower die part in sheet metal die assembly is fixed to ground. In order to define that in MECHANICA we have to assign zero displacement constraint to lower portion of Lower die. Now the model will appear similar to following figure. Figure 3.4-5: ASSIGNING DISPLACEMENT CONSTRAINT 31 3.4.5) DEFINING PLANAR CONSTRAINT: In order to distribute uniform load on upper die by the pressure applied we have to define a planar constraint. This can be shown in following figure. Figure 3.4-6: ASSIGNING PLANAR CONSTRAINT 32 3.4.6) RUNNING BASIC STATIC ANALYSIS: Now we have to set up basic analysis from the pull down menu by selecting Analyses and Design studies. Initially the analysis is run using Quick check and it detects any errors in the model. Once we pass through this step the analysis is runes again by single and multi-pass adaptive methods. The setting up of basic analysis is shown in following figures. Figure 3.4-7: SETTING UP BASIC ANALYSIS 33 Figure 3.4-8: RUNNING BASIC ANALYSIS 34 3.4.7) RUNNING AUTO GEM: The finite element analysis mesh is created by using automatic mesh generator, Auto Gem in MECHANICA. After running this the main items which we can know are number of elements created, convergence on pass, maximum Von Misses stress, maximum displacement, CPU time and elapsed time. These can be seen in following figure. Figure 3.4-9: RUNNING AUTO GEM 35 3.4.8) MECHANICA CONVERGENCY: In order to converge the mesh size in MECHANICA we have to run the basic static analysis in three ways i.e. Quick check, Single pass adaptive and Multi pass adaptive. Quick check is done in order to check the die assembly is properly constrained or not. Once the quick check is done then it is run in Single pass Adaptive test in order to ensure that we get the basic deflections, stress and strain results. Then we have to run again with Multi Pass Adaptive test by setting maximum polynomial order to 9 and percentage of convergence to 5.Then the Auto Gem is runned again and it calculates several equations and we get final mesh which is converged and ready to set for the optimum design conditions. Figure 3.4-10: SETTING UP CONVERGENCE 36 Figure 3.4-11: RUNNING MULTI-PASS ADAPTIVE TEST Summary of Multi-Pass Adaptive test from MECHANICA program: Mechanica Structure Version L-03-38:spg Summary for Design Study "basic_static" Mon Nov 15, 2010 12:21:50 -----------------------------------------------------------Run Settings Memory allocation for block solver: 128.0 Parallel Processing Status Parallel task limit for current run: 37 Parallel task limit for current platform: 64 Number of processors detected automatically: 2 Checking the model before creating elements... These checks take into account the fact that Auto GEM will automatically create elements in volumes with material properties, on surfaces with shell properties, and on curves with beam section properties. Generate elements automatically. Checking the model after creating elements... No errors were found in the model. Mechanica Structure Model Summary Principal System of Units: Inch lbm Second (Pro/E Default) Length: in Mass: lbm Time: sec Temperature: F Model Type: Three Dimensional Points: 5640 Edges: 28786 Faces: 40676 Springs: 0 Masses: 0 Beams: 0 38 Shells: 0 Solids: 1765 Elements: 17650 ------------------------------------------------------------Standard Design Study Static Analysis "basic_static": Convergence Method: Multiple-Pass Adaptive Plotting Grid: 4 Convergence Loop Log: (12:23:00) >> Pass 1 << Calculating Element Equations (12:23:03) Total Number of Equations: 15324 Maximum Edge Order: Solving Equations Post-Processing Solution 1 (12:23:04) (12:23:04) Calculating Disp and Stress Results Checking Convergence Elements Not Converged: (12:23:06) (12:23:36) 17650 Edges Not Converged: 28786 Local Disp/Energy Index: 100.0% Global RMS Stress Index: 100.0% Resource Check (12:23:37) 39 Elapsed Time (sec): CPU Time 108.64 (sec): Memory Usage 88.34 (kb): 418453 Wrk Dir Dsk Usage (kb): 139264 >> Pass 2 << Calculating Element Equations (12:23:40) Total Number of Equations: 97787 Maximum Edge Order: 2 Solving Equations (12:23:43) Post-Processing Solution (12:23:50) Calculating Disp and Stress Results Checking Convergence (12:23:56) (12:24:24) Elements Not Converged: 4023 Edges Not Converged: 0 Local Disp/Energy Index: 100.0% Global RMS Stress Index: 67.7% Resource Check (12:24:25) Elapsed Time (sec): 156.64 CPU Time (sec): 121.28 Memory Usage (kb): Wrk Dir Dsk Usage (kb): 468541 295936 40 >> Pass 3 << Calculating Element Equations (12:24:29) Total Number of Equations: 181082 Maximum Edge Order: 3 Solving Equations (12:24:32) Post-Processing Solution (12:24:53) Calculating Disp and Stress Results Checking Convergence (12:25:01) (12:25:33) Elements Not Converged: 3770 Edges Not Converged: 0 Local Disp/Energy Index: 100.0% Global RMS Stress Index: 61.9% Resource Check (12:25:35) Elapsed Time (sec): 226.33 CPU Time (sec): 180.19 Memory Usage (kb): Wrk Dir Dsk Usage (kb): 509307 655360 >> Pass 4 << Calculating Element Equations (12:25:38) Total Number of Equations: 339702 Maximum Edge Order: 4 41 Solving Equations (12:25:48) Post-Processing Solution (12:26:38) Calculating Disp and Stress Results Checking Convergence (12:26:51) (12:27:29) Elements Not Converged: 3131 Edges Not Converged: 0 Local Disp/Energy Index: 100.0% Global RMS Stress Index: 38.6% Resource Check (12:27:34) Elapsed Time (sec): 345.51 CPU Time (sec): 309.33 Memory Usage (kb): Wrk Dir Dsk Usage (kb): 566982 1487872 >> Pass 5 << Calculating Element Equations (12:27:38) Total Number of Equations: 598057 Maximum Edge Order: Solving Equations Post-Processing Solution 5 (12:28:28) (12:32:00) Calculating Disp and Stress Results Checking Convergence (12:32:27) (12:33:14) 42 Elements Not Converged: 2004 Edges Not Converged: 0 Local Disp/Energy Index: 72.9% Global RMS Stress Index: 25.0% Resource Check (12:33:33) Elapsed Time (sec): 704.35 CPU Time (sec): 663.48 Memory Usage (kb): Wrk Dir Dsk Usage (kb): 673600 3394560 >> Pass 6 << Calculating Element Equations (12:33:36) Total Number of Equations: 981628 Maximum Edge Order: Solving Equations 6 (12:35:48) Post-Processing Solution (12:46:16) Calculating Disp and Stress Results Checking Convergence (12:47:12) (12:48:26) Elements Not Converged: 1076 Edges Not Converged: 0 Local Disp/Energy Index: 54.4% Global RMS Stress Index: 17.8% 43 Resource Check (12:48:47) Elapsed Time (sec): 1618.26 CPU Time (sec): 1648.78 Memory Usage (kb): 783599 Wrk Dir Dsk Usage (kb): 7080960 >> Pass 7 << Calculating Element Equations (12:48:51) Total Number of Equations: 1503838 Maximum Edge Order: 7 Solving Equations (12:54:12) Post-Processing Solution (13:22:10) Calculating Disp and Stress Results Checking Convergence (13:24:16) (13:26:06) Elements Not Converged: 586 Edges Not Converged: 0 Local Disp/Energy Index: 41.7% Global RMS Stress Index: 13.6% Resource Check (13:26:47) Elapsed Time (sec): 3897.89 CPU Time (sec): 4129.66 Memory Usage (kb): 953660 44 Wrk Dir Dsk Usage (kb): 13493248 > Pass 8 << Calculating Element Equations (13:26:51) Total Number of Equations: 2171995 Maximum Edge Order: 8 Solving Equations (13:30:48) Post-Processing Solution (13:40:25) Calculating Disp and Stress Results Checking Convergence (13:45:1 (13:50:26) Elements Not Converged: 293 Edges Not Converged: 0 Local Disp/Energy Index: 31.2% Global RMS Stress Index: 8.9% Resource Check (13:58:58) Elapsed Time (sec): 4987.22 CPU Time (sec): 6129.55 Memory Usage (kb): Wrk Dir Dsk Usage (kb): 1053660 1843584 >> Pass 9 << Calculating Element Equations (13:58:58) Total Number of Equations: 2858445 45 Maximum Edge Order: 9 Solving Equations (14:10:25) Post-Processing Solution (14:35:20) Calculating Disp and Stress Results Checking Convergence (14:47:12) (14:57:35) Elements Not Converged: 0 Edges Not Converged: 0 Local Disp/Energy Index: 20.9% Global RMS Stress Index: 7.5% Resource Check (15:10:33) Elapsed Time (sec): 5123.66 CPU Time (sec): 7895.22 Memory Usage (kb): Wrk Dir Dsk Usage (kb): 1543680 2048657 Hence from above all passes i.e. from 1 to 9 all elements are converged and then we run optimum design analysis. 46 3.4.8) SETTING UP OPTIMUM DESIGN STUDY: Now, the conditions which are required to be satisfied in the design are given in optimum design study. The conditions given are low overall displacement and the height to of pins on blank holder. The setting up and running the optimum design study is shown in following figures respectively. Figure 3.4-12: SETTING UP OPTIMUM DESIGN STUDY 47 Figure 3.4-13: RUNNING OPTIMUM DESIGN STUDY 48 Chapter 4 RESULTS 4.1) RESULTS FROM BASIC STATIC ANALYSIS: Maximum Deflections:1.667in Maximum Stress:324.3Mpa Maximum Strain:0.134 Height of Pin:2.9526in Height of upperdie:21.2598in 4.2) RESULTS FROM OPTIMUM DESIGN STUDY ANALYSIS: Maximum Deflections:1.922e^-03in Maximum Stress:293.2Mpa Maximum Strain:1.294e^-04 Height of Pin:2.899in Height of upperdie:20.99in These results can also be seen in graphical and fringe views by MECHANCIA tool. These are as follows. 49 4.3) BASIC STATIC Vs OPTIMIZATION-DEFLECTIONS: Figure 4.3-1: DEFLECTIONS IN FRINGE DISPLAY TYPE 50 4.4) BASIC STATIC Vs OPTIMIZATION-STRESSES: Figure 4.4-1: STRESSES IN FRINGE DISPLAY TYPE 51 Maximum Stress –Basic Static Maximum Stress-Optimization Figure 4.4-2: MAXIMUM STRESS LOCATIONS 52 4.5) BASIC STATIC Vs OPTIMIZATION-PRINCIPAL STRAIN: Figure 4.5-1: PRINCIPAL STRAIN IN FRINGE DISPLAY TYPE 53 Maximum Strain-Optimization, Basic Static Figure 4.5-2: MAXIMUM PRINCIPAL STRAIN LOCATIONS 54 4.6) DIMENSIONAL CHANGES IN DIE ASSEMBLY: After running optimum design study we get the dimensional changes in height of pins and upper die and these can be shown in following figure. Figure 4.6-1: DIMENSIONAL CHANGES IN DIE ASSEMBLY 55 4.7) GRAPHICAL RESULTS: The graphical results in MECHANICA can be known by considering certain area in sheet metal die assembly. In present paper the top surface of the blank holder is considered one of the areas where we interested to see graphical results. The area we considered can be shown in following figure. Figure 4.7-1: GRAPHICAL AREA CONSIDERED The deflections at this area for basic static analysis and optimization can be viewed in following figure. 56 Figure 4.7-2: DEFLECTIONS IN GRAPHICAL DISPLAY TYPE 57 4.8) OPTIMIZED AUTO GEM: After optimization the auto gem is runned again and the result can be seen in following figure. Figure 4.8-1: AUTO-GEM AFTER OPTIMIZATION 58 Chapter 4 FEATURE WORK Modification in designing to make it more robust. Finite Element Analysis of complete sheet metal die assembly including blank sheet and pattern. Vibration Analysis. Using any other FEA tool in getting more appropriate results. 59 REFERENCES 1. Pro | ENGINEER WILDFIRE 3.0 BASIC DESIGN Steven G.Smith 2. Pro | ENGINEER WILDFIRE 3.0 MECHANICA TUTORIAL Roger Toogood, SDC PUBLICATIONS 3. www.wikipedia.com