WHS Admin Area Inspection Checklist - University of Tasmania

advertisement

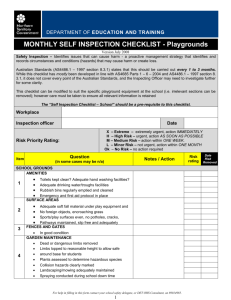

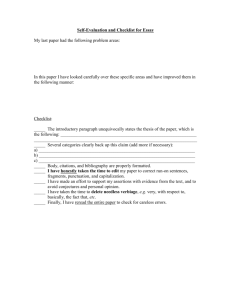

Work Health and Safety Administration Area Inspection Checklist (Note – this checklist is also appropriate for computer laboratories and learning spaces) Inspection team members:__________________________________________________________ Area or Room no.:__________________________________ Inspection date:_____________________ Workplace inspections are planned, systematic appraisal of the workplace which: Identify health and safety hazards; Assess and control risks; Ensure a safe and healthy working environment, and Assist in complying with work health and safety legislation. The University values the contribution of every staff member in making the University a safer and healthier place to work. The completion of workplace checks provides staff with an additional opportunity to identify hazards within their immediate workplace, hazards that the University may not otherwise be aware of. Workplace inspections can and do provide the basis for meaningful and productive consultation between staff, their elected Health and Safety Representatives and the University. The University recognises that a staff member undertaking an inspection is only able to identify hazards within the limitations of their health and safety knowledge and experience. For further advice about ergonomic assessments or any other health and safety matter please contact your WHS Advisor or the WHS Unit at health.safety@utas.edu.au Instructions: Boxes to be marked with a tick (√), as items are sighted or with a cross (x) if not present. Otherwise N/A indicates the item is not applicable to this laboratory. Any questions marked with a cross require a comment or detail to be added. General House Keeping The general area is tidy and free of obstruction such as slip/trip hazards (uneven floors, power leads etc) Doors are fully functional Floor coverings adequate/clean Windows clean and operational Stock /material stored safely Photocopiers not located close to workstations Noise level adequate – does not interfere with communication Exit doors marked and clearly visible Exit doors can be opened from Date: August 2014 WHS Checklist – Administration Areas University of Tasmania Work Health and Safety Administration Area Inspection Checklist inside The layout of the work areas are suitable for the tasks Temperature in room/area is appropriate and airflow is adequate Electrical Sufficient power points for equipment Light switches/power points/ plugs/leads appear in good order Power boards with overload protection are used if insufficient powerpoints All electrical equipment tested at appropriate intervals with current tags Heaters/fans safety located and in working order with current tags Light fittings including diffusers, reflectors, tubes/bulbs are clean and in good order No unauthorised personal electrical items in use Lighting Adequate in general areas No flickering/inoperable lights Task lighting available as needed Windows clean Emergency lighting system installed and operational Workstations Is this section relevant? [Yes] [No] (if no, go to next section) Wheel base office chairs have 5 point wheel base Office chairs are fully adjustable (if appropriate) Chairs are in good order and appropriate for task There is adequate space around the rear and side of chairs to allow for unrestricted movement Footrests available if required Work surfaces are set up to the correct height: 680 – 720mm for seated work 900 – 950mm for standing work Ergonomic workstation assessments offered as required Date: August 2014 WHS Checklist – Administration Areas University of Tasmania Work Health and Safety Administration Area Inspection Checklist Computer equipment The computer screen is at arm’s length to the user The computer screen is at the correct height for the user The computer screen is directly in front of the user The computer screen is positioned to minimise glare The position of the keyboard is correct for the user The mouse is at the same height as the keyboard Emergency procedures Evacuation procedures clearly displayed Emergency exits clearly marked/functional Emergency exits unobstructed Emergency personnel identified and contact numbers displayed and current A first aid kit is available in the near vicinity or signage to indicate where nearest kit is List of trained first aid officers and contacts displayed and current Fire equipment is accessible and free of obstruction Fire extinguishers have been inspected and tagged within last 12 months Storage areas Is this section relevant? [Yes] [No] (if no, go to next section) Is this section relevant? [Yes] [No] (if no, go to next section) Area is neat and tidy Heavier items stored between knee and shoulder height Safe means of accessing high shelves eg approved steps Floors around storage area clear and free of rubbish Sufficient space to move materials Stored materials are secured to prevent shifting/falling No sharps edges File cabinets allow only one drawer open at a time Manual handling Date: August 2014 WHS Checklist – Administration Areas University of Tasmania Work Health and Safety Administration Area Inspection Checklist Mechanical aids or equipment supplied and adequate eg trolleys Manual handling risk assessments performed and available Manual handling controls implemented ie storage of heavy items is between knee and should height Manual handling training provided Kitchen areas Is this section relevant? [Yes] [No] (if no, go to next section) [Yes] [No] (if no, go to next section) Sinks and preparation areas are clean Area is free of vermin or evidence of their presence Stoves and appliances are clean and operational Fridges are clean, hygienic and de-frosted Microwaves are positioned at suitable height, clean and operational All utensils, equipment and other items stored adequately All cleaning products stored separately from foodstuffs Dishwasher or adequate manual washing facilities available Rubbish is disposed of appropriately (re-cycling provided where applicable) Hazardous chemicals Is this section relevant? Any hazardous chemicals are stored appropriately All containers are labelled correctly Safety Data Sheets are available for hazardous chemicals Stairs, steps and landings Is this section relevant? [Yes] [No] (if no go to next section) No worn or broken stairs Handrails in good repair Clear of stored material, debris and spills Non-slip treatments in good condition Adequate lighting Emergency lighting Date: August 2014 WHS Checklist – Administration Areas University of Tasmania Work Health and Safety Administration Area Inspection Checklist Other comments Date: August 2014 WHS Checklist – Administration Areas University of Tasmania