Work environmnet

advertisement

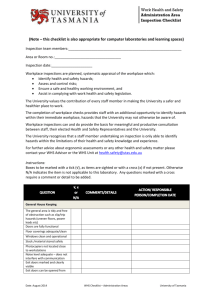

ANU Workplace Inspection Program Inspection Reference Sheet – Work Environment H. Induction, Training and Raising WHS Issues H.1 The area/department/unit has an induction process for new staff that covers WHS issues. H.2 Safety training programs are made available to staff, students and visitors H.3 Staff (and students) are aware of how to raise WHS issues through their supervisor, WHS Committee member, HSR or Work Environment Group I. I.1 Lighting Lighting levels are sufficient and not excessive for: general tasks movement throughout the workplace tasks that have specific lighting requirements I.2 Glare from both external and internal light is controlled I.3 Light fittings, including diffusers, reflectors, tubes/bulbs, are clean and in good condition I.4 Laser Pointers are Class 1 or Class 2 only (Hazard Alert 2011) J. J.1 K. Noise Exposure to noise (quality and quantity) is eliminated or minimised Ventilation K.1 General ventilation provides fresh air and air movement K.2 Temperature & humidity control is sufficient K.3 Photocopiers are located away from personal workstations K.4 Are people aware of how to achieve good ventilation (i.e. open windows when required) L. Waste management L.1 There are sufficient and appropriate waste disposal containers L.2 Waste bins are routinely emptied L.3 Hazardous waste is appropriately stored and labelled M. Housekeeping M.1 Access and egress routes are well defined and kept clear at all times M.2 Desktops, benches and working surfaces are clean and free from clutter, scrap and waste materials M.3 The area is free of accumulated equipment, stores, rubbish, etc M.4 Combustible or flammable materials are a safe distance from heating appliances, e.g. room heaters, stoves in kitchens or heat-generating devices, photocopiers, laminators, equipment and machinery ANU WHS Workplace Inspection – Work Environment Work Environment Group HR Division Version 5:1/2014 Page 1 of 2 N. Handling and storage of materials N.1 Mechanical aids or equipment are available for handling (heavy/awkward) materials N.2 Materials are stored on shelves or in storage rooms, as appropriate N.3 Storage of heavy items above shoulder height is avoided N.4 Stored material is secured to prevent shifting/falling N.5 Storage units are free of rubbish N.6 Storage units are properly constructed and secured to prevent falling N.7 Storage rooms are neat and tidy allowing safe movement N.8 Steps (with hand rail) are available to access higher shelves (if storage at those heights are unavoidable) O. Hygiene O.1 Clean and separate meal rooms are provided O.2 Drinking water is readily available O.3 Adequate washing facilities are provided O.4 There are sufficient toilets for the expected number of people O.5 Lockers or hangers are provided for work-clothes O.6 Staff amenities are kept clean ANU WHS Workplace Inspection – Work Environment Work Environment Group HR Division Version 5:1/2014 Page 2 of 2