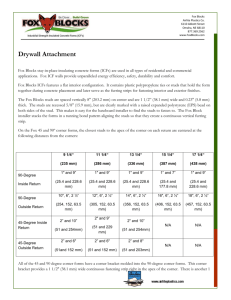

Avoiding Drywall Joint Cracks

advertisement

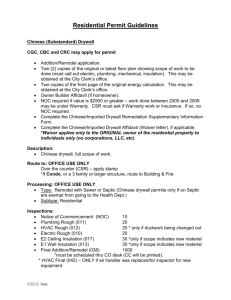

Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com Avoiding Drywall Joint Cracks It is very important to fasten drywall properly and to control and monitor the interior humidity and temperature once the Fox Block ICF walls are stacked, the concrete is placed, and the building envelope is enclosed. New construction has new materials and the materials typically have some amount of moisture. The Fox ICF wall also has fresh concrete that is going through the curing process. As the moisture from the concrete wall and new materials vaporize, it increases the humidity levels inside the building’s shell. Controlling Humidity and Temperature When the drywall is fastened to the interior walls it is critical to control and monitor the humidity level and keep the interior at a constant temperature. If the humidity is not controlled under certain conditions, the water vapor exiting the ICF concrete wall could eventually lead to drywall cracking along the drywall joints. The drywall joint is a weak link consisting of drywall joint compound and joint tape. Moisture can potentially cause the drywall to swell leading to joint cracking. If the humidity and temperature is not controlled properly after the building is enclosed both before and after occupancy, the moisture can lead to drywall cracks. It is recommended to control and monitor the humidity and temperature both during construction after the building is enclosed and after occupancy. Moisture will continue to evaporate for up to the first 12 months of occupancy. If the humidity is not controlled it could lead to condensation on windows and moisture creating problems with different materials. Fastening the Drywall Typically the drywall is hung horizontally with the longer side (i.e. 8’ or 12’) of the drywall running horizontal and the short side (4’) running vertical. There are two types of joints - a butt joint and a tapered joint. The drywall edges are tapered on the long sides (i.e. 8’ or 12’) and the drywall edges are square cut on the short sides (4’). Therefore the taper joint runs horizontally and the butt joint runs vertically. The drywall must be attached to the Fox ICF wall using a #6 or greater sharp point course thread drywall screw spaced as required by the applicable code but no greater than 30 inches apart both horizontally and vertically. The horizontal tapered joint can be fastened up to every 8 inches on center and should not exceed 30 inches on center. Fox Blocks recommends a maximum fastening spacing of 24 inches on center equal distance across each 48 inch long form. This places two fasteners horizontally along each ICF form. The vertical butt joint should be placed either equal distance over the 1 1/2” wide plastic furring strip or at midpoint between two plastic furring strips. Avoid having one sheet of drywall extending past a plastic furring strip more than the other sheet of drywall. Preferably Fox Blocks recommends using two screws spaced equal distance per each 16” height course of Fox ICF forms. In addition to fastening the drywall with screws, it is recommended to run either a bead of glue or spot glue using compatible glue along each side of the butt joint within an inch or two of each drywall Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com edge. Control Joints Gypsum wallboard is subject to some form of movement induced by changes in moisture and temperature just like any other building product. Control joints are necessary in walls to relieve the stresses that occur from this movement. Control joints are added to prevent cracking in gypsum wallboard due to movement. Control joints should be incorporated in 30 foot intervals. ASTM C 840 and GA-216 are two standards where the requirements for control joints are addressed.