FST 407 Lecture Note - The Federal University of Agriculture

advertisement

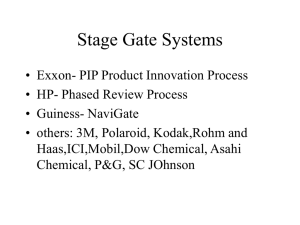

FST 407: Food Product Development 3 units Dr Mrs J. M. Babajide Department of Food Science and Technology, University of Agriculture, Abeokuta Course requirements: CAT: 20% Course Project: 20% Exam: 60% 70% Class attendance compulsory LECTURE 1 Introduction Course Philosophy •The commercial end result of Food Science and Technology is the delivery of acceptable foods to consumers. •This course will immerse students in the product development process using the product development team approach that is prevalent in the food industry. • Students will be required to acquire the knowledge necessary to successfully complete their project assignment. •As in the industry, achievement of team goals will be rewarded. Expected outcomes for the course…. Students must 1. Be able to identify the processes and stages required to bring a new food product from conception to commercialization. 2. Have produced in the laboratory a prototype of a new product that has a high probability that it could be produced commercially. 3. Be aware of the dynamics of working on a product development team. 4. Understand how to write a product formula and finished product specifications. 5. Know what technical and scientific data must be available before a product can be manufactured. 6. Be aware of the dynamics of working on a product development team. WHAT IS A PRODUCT ? •Product - A product is a good, service, or idea consisting of a bundle of tangible and intangible attributes that satisfies consumers and is received in exchange for money or some other unit of value. •Product Attributes - The characteristics by which products are identified and differentiated. Product attributes usually comprise features, functions, benefits, and uses. LECTURE 2 The Product development process can be divided into three segments •Concept •Prototype •Final Product Development of 3 products for concept evaluation Students to: • Come to the next class with lots of product ideas • Share your ideas with your team mates and reduce number of ideas • Condense the list to 3 by the end of the first laboratory period • Begin concept testing during second lab. period Why Group Projects? • Students often learn better from each other • Work from a well-functioning group is better and more complete than any individual’s work • Develop group interaction skills • Real situation in today’s food industry LECTURE 3 IDEATION TESTING One of the most important aspects of product development in the soundness of the development of the concept. Common methods for evaluating concepts include: •Perceptual Map •Gap analysis •Product attractiveness score. LECTURE 4 What is a Product Development Process? • Stage Gate Process – Developed by Robert Cooper/ McGill University – Stage-Gate Product Development processes builds on Robert Cooper's studies of over 2,000 projects to identify the best practices in new product development. • Stage-Gate is a template, or roadmap, for driving new product projects from idea to launch and beyond. • It is one of the world's most widely used processes across multiple industries. What is a Product Development Process? How it works: New product development begins with an idea and ends with the launch of a new product. The steps between these points can be viewed as a systematic product development process. The Product Development Process divides these into a series of stages. Stages 0 1 1 2 2 3 3 Gates 4 4 5 5 6 6 Why a Product Development Process? • • • • Reduction of Risk Better Management of Resources Repeatability of Development Focus on Decision Making What are the components of a Product Development Process? Stages: • Each stage contains a set of prescribed and concurrent activities, incorporating industry best practices. The activities during a stage are executed in parallel, not in sequence. • Each stage is preceded by a gate. What are the components of a Product Development Process? Gates: • Gates are the points in the process where a decision must be made. The gate-keepers can choose to Go, Kill, Hold, or Recycle the project. • It is where project prioritization and resource allocation decisions are made. At the end of a gate meeting, a decision must be reached. If the decision is Go, this ensures resource commitments and support from the management. What are the components of a Product Development Process? Gatekeepers: • Gatekeepers are the team of senior management who make Go/Kill decisions at gates. What does a Typical Stage-Gate Process look like? “It’s a Funnel” Concept Idea 0 1 • Detail: more 1 Scale Up Develop Test/ Validation Business Case 2 2 3 3 4 4 Post Launch Audit Launch 5 5 6 6 As you move from beginning to end the data gets detailed. • Mindset: The first few stages focus on creativity and new ideas. • The last few stages focus on execution and analyses. Overview of a Typical Product Development Process 0 • • • • • • • 1 1 2 2 3 3 Stage 0 Discovery/ Ideation Stage 1 Concept Stage 2 Build Business Case Stage 3 Development Stage 4 Testing & Validation Stage 5 Launch Stage 6 Post Launch Audit 4 4 5 5 6 6 Key Decisions throughout the Process • • Stage 0: Idea/ Planning and Situation Analysis Gate 1: Decision to do a preliminary investigation Stage 1: Preliminary investigation/ Consumer Needs &Idea Generation Gate 2: Decision to build a business case • Stage 2: Detailed investigation and business case/ Concept Development Gate 3: Decision to go into development Stage 3: Development/ Feasibility Confirmation Gate 4: Decision to go into testing and validation • Stage 4: Testing and validation/ Scale up Confirmation Gate 5: Decision to go into full production and market launch Stage 5: Full launch and final report/Product Launch Gate 6: Project Termination • Stage 6: Post Launch Audit/ Key Learning’s Key Questions to answer all the way through – – – – Does Someone want the product? Can We sell the product? Can We make the product? Can We make money at this? LECTURE 5 What Drives Success? #1 • Unique and Superior Product • Differentiated Product • Delivers unique Benefits • Delivers Superior value to the Consumer Type of Product Me Too Moderate Advantage Superior % Succeed Market Share Profit Rating 18.4% 11.6% 2.6/10 58.0% 32.4% 5.8/10 98.0% 53.5% 8.4/10 What Drives Success? # 2 Strong Market Orientation. Market driven and consumer focused. --- Good Market research # 3 International Orientation Global vs Glocal # 4 Pre Development Homework # 5 Sharp and Early Product/ Project Definition # 6 Well Conceived Market Launch # 7 The Right Organizational Structure # 8 Top Management Support # 9 Leveraging Core Competencies # 10 Projects Aimed at Attractive Markets The Cost of being Second…Can be High Order Entry Sales as % of Entrant # 1 1 100% 2 70-75% 3 55-65% 4 50-55% 5 45-55% 6 40-50% General Reasons for New Product Failure % Citing Reasons for Failure • • • • • • • • 45% Marketing Analysis 30% Product Problems or Defects 25% Marketing Efforts not Enough 18% Higher Costs than Expected 17% Competitive Strength or Reaction 15% Poor Timing of Introduction 11% Technical or Production Problems 22% All Other Source: Robert Cooper 2003 LECTURE 6 Turning a Concept into a Product OBJECTIVES • TO DETERMINE HOW THE CONCEPT CAN BE TURNED INTO A PRODUCT • TO OBTAIN AN INITIAL PRODUCT FOR EVALUATION • TO UNDERSTAND ALL FACTORS AFFECTING PRODUCT ATTRIBUTES • TO SCREEN INGREDIENTS AND FORMULATIONS • TO ASSESS PROCESSING REQUIREMENTS • TO ASSESS PACKAGING AND STORAGE NEEDS Steps in the Process • Protocept • Prototype • Final Product PROTOCEPT DEFINITION • A protocept is the product developed in the laboratory to meet the promises of the product concept • Protocept can be developed through interation until ready for prototype development • Protocepts may not be technically feasible PROTOTYPE DEFINITION • A Prototype is The Outcome of a Protocept, Generally Optimized Through Pilot Plant Trials • Generally Utilizes Appropriate Statistical Designs for Optimization at the Pilot Plant Scale • Prototypes are technically feasible PROTOCEPT DEVELOPMENT • • • • • • • • • • • Interpretation of the Concept Product Attributes Formulation – Ingredient Selection Processing Steps and Conditions Established Specifications Product Assessment Packaging HACCP Shelf Life Evaluation Pricing Consideration Of Regulation Compliance LECTURE 7 SCALE-UP • Definition – Act of using results obtained from laboratory studies for designing a prototype and a pilot plant process; construction a pilot plant and using pilot plant data for designing and constructing a full scale plant or modifying an existing plant Steps in Scale-Up • Define product economics based on projected market size and competitive selling and provide guidance for allowable manufacturing costs • Conduct laboratory studies and scale-up planning at the same time • Define key rate-controlling steps in the proposed process Steps in Scale-Up • Conduct preliminary larger-than-laboratory studies with equipment to be used in rate-controlling step to aid in plant design • Design and construct a pilot plant including provisions for process and environmental controls, cleaning and sanitizing systems, packaging and waste handling systems, and meeting regulatory agency requirements • Evaluate pilot plant results (product and process) LECTURE 8 SPECIFICATIONS • DEFINITION (WEBSTER’S NEW COLLEGIATE DICTIONARY) – “SPECIFY” – 1: to name or state explicitly or in detail – 2: to include as an item in a specification Components in specifications • Composition • Safety • performance LECTURE 9 HOW TO RUN A PLANT TRIAL MODULE • To learn about the need for plant trials • To learn the basic steps in running a plant trial • To hear some advice on mistakes to avoid PLANT TRIAL DEFINITION A Plant Trial is a test production run on commercial scale equipment intended to validate the process defined to make a product and the scale-up calculations used. WHEN DO YOU RUN A PLANT TRIAL? • After a process has been defined in the pilot plant • Before a product launch • When you need product for a consumer test BASIC STEPS IN CONDUCTING A PLANT TRIAL 1. 2. 3. 4. 5. 6. 7. 8. Define objectives Plan trials Schedule plant time Brief plant management Brief and train operators Conduct trial Evaluate product Debrief plant management Process Flow Sheet and Process Optimization Module • Know what a process flow chart is • Understand the need to optimize process conditions A Flow Chart is a schematic depiction of the process required to make a given product. It contains all the information needed for process scale-up, design and cost determination. LECTURE 10 Packaging Considerations Module • To learn Product Development’s role in developing new packages • To learn what factors to consider for new packaging Product Development Priorities Product Protection Through Distribution Through Shelf Life Through Consumption Thick Package Walls Functionality Clear Use Instructions Easy to Open Easy to Handle Resealable Storable Package Safety Non-breakable Sanitary Marketing Priorities • • • • • • • • Big Front Panel Large Print Size Billboard Possibilities Consumer Friendly Language Branding Package Clarity Differentiating Attractive Purchasing Priorities • • • • Low Cost Multiple Suppliers Long Relationships Thin Wall Packages (Light weighted) Legal Priorities Legal Name Company Address Net Weight Ingredient Label Nutritional Label Claims Contingent Language (“may contain peanuts”) Big Principal Display Panel Large Print Common Name No Small Parts Enemies of Packaged Food Quality Light Oxygen Water Insects and Rodents Microorganisms Bacteria Yeasts and Mold Time Temperature People and Transportation KEY TO NOTE • Start Package development early because it can be a very complex process requiring compromises and trade offs. LECTURE 11 PRODUCT PERFORMANCE OBJECTIVES • To understand the factors that control the performance of a food product • To know when, where, how and what to evaluate to determine performance Rollout When are you ready? • Advertising and promotional strategies –in place, taking into account competition and consumer response in test markets- roll of advertising agencies or in-house groups. • Pricing strategy for product vs. competition? • Manufacturing process yield products meeting consumer acceptance, quality, safety, shelf life, cost, and regulatory requirements. Measures of Rollout Success • Return on investment analysis • Consumer reaction – did they like it?, repeat purchases? • Sales volume , market penetration, market share? Did they meet goals? • Pay-back, did profits meet objectives? Each group shall submit a developed product with a well written report at the end of the course work as COURSE PROJECT.