Steady state conduction 1D

advertisement

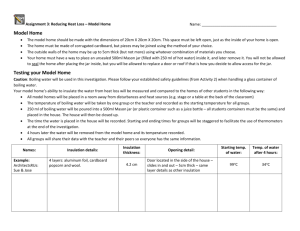

ERT 216 HEAT & MASS TRANSFER Sem 2/ 2014-2015 Dr Akmal Hadi Bin Ma’ Radzi School of Bioprocess Engineering University Malaysia Perlis Conduction 1) Steady state conduction- One dimension 2) Steady state conduction- Multiple dimension 3) Unsteady state conduction Steady State ConductionOne Dimension (1D) Point of view Application of Fourier’s law of heat conduction to calculation of heat flow in simple 1D system (1) Plane Wall (2) Cylinders Radial Systems (3) Spherical 1D The temp. in the body is a function only of radial distance and independent of azimuth angle/ axial distance (1) The Plane Wall Integrated Fourier’s law # If k varies with temp. according linear relation , the heat flow become; # If 3 material (multilayer wall) involved, heat flow become; Note: The heat flow must be SAME through all section Electrical analog circuit # The heat flow rate also can be represented as resistance network; (Different conceptual view point for Fourier’s law) Thermal resistance (°C/W) Consider Heat transfer rate as flow and combination of as a resistance to this flow. The temp. is the potential function of the heat flow. So that, the Fourier equation may be written as: 3 wall side by side act as 3 thermal resistance in series Electrical analog circuit: used to solve more complex problem (series and parallel thermal resistance) Electrical analog circuit Parallel Series Insulation & R value • The performance of insulation R value, define as • Guide to choose insulating material in terms of their application and allowable temperature range (2) Cylinders From Fourier’s Law Integrate this with the boundary conditions The heat flow rate (2) Cylinders Thermal resistant for cylinder is (2) Cylinders Multiple cylindrical sections Thermal-resistance concept for multiple-layer cylindrical walls = Thermal-resistance concept for plane wall So that, the heat flow rate (3) Spheres The heat flow rate Prove this equation!! Convection Boundary Conditions Newton rate equation /Newton’s Law of cooling So that, an electric-resistance analogy for convection process become: Example 1: (Multilayer plane wall conduction) An exterior wall of a house may be approximated by a 4-in layer of common brick (k= 0.7 W/m.°C) followed by a 1.5-in layer of gypsum plaster (k=0.48 W/m.°C). What thickness of loosely packed rock wool insulation (k=0.065 W/m.°C) should be added to reduce the heat loss (or gain) through the wall by 80%? Example 2: (Multilayer Cylindrical System) A thick-walled tube of stainless steel [18% Cr, 8% Ni, k=19 W/m.°C ] with 2 cm inner diameter (ID) and 4 cm outer diameter (OD) is covered with a 3 cm layer of asbestos insulation [k=0.2 W/m.°C ]. If the inside wall temperature of the pipe is maintained at 600 °C, calculate the heat loss per meter of length. Also calculate the tube-insulation interface temperature. The Overall Heat Transfer Coefficient, U 1/ h A represent the convection resistance; ∆x/ k A represent the conduction resistance The overall heat transfer (conduction + convection) can be expressed in term of an overall heat transfer coefficient, U defined by relation: A: Area for the heat flow The Overall Heat Transfer Coefficient U also related to the R-value: Where, The Overall Heat Transfer Coefficient, U Consider: Hollow cylinder exposed to a convection environment on its inner and outer surfaces with TA and TB the two fluid temp. The area for convection is not same for both liquids (depend on the inside tube diameter and wall thickness The overall hate transfer rate become; Overall temp. difference The sum of the thermal resistances The Overall Heat Transfer Coefficient, U Ai & Ao: Inside & outside surface areas of the inner tube The Overall Heat Transfer Coefficient (Hollow cylinder) based on: 1) Inside area of the tube Ai 2) Outside area of the tube, Ao The Overall Heat Transfer Coefficient, U The general notion (plane wall or cylinder coordinate system) is that; Rth Thermal resistance Info Some typical value of U for heat exchanger are given in table. Some value of U for common types of building construction system also given in table and employed for calculation involving the heating and cooling buildings. Example 3 A house wall may be approximated as two 1.2 cm layers of fiber insulating board, an 8.0 cm layer of loosely packed asbestos, and a 10 cm layer of common brick. Assuming convection heat transfer coefficient of 12 W/m2. °C on both sides of the wall, calculate the overall heat transfer coefficient for this arrangement. Solution Example 4 A wall is constructed of a section of stainless steel [k=16 W/m. °C] 4.0 mm thick with identical layers of plastic on both sides of the steel. The overall heat transfer coefficient, considering convection on both sides of the plastic, is 120 W/m2.°C. If the overall temp. different across the arrangement is 60 °C, calculated the temperature difference across the stainless steel. Solution Critical Thickness of Insulation Consider: A layer of insulation which might be installed around a circular pipe. The inner temp. of the insulation is fixed at Ti and the outer surface is exposed to a convection environment at T∞. The heat transfer in the thermal network term Critical Thickness of Insulation Manipulated this equation to determine the outer radius of insulation, ro, which will maximize the heat transfer. The maximization condition is : The result is (The critical-radius-of insulation concept) Critical Thickness of Insulation The critical-radius-of insulation concept Concept 1) If ro < critical radius value, means: The heat transfer will be increased by adding more insulation thickness 2) If ro > critical radius value, The heat transfer will be decrease means: Example 5 A 1.0 mm diameter wire is maintained at a temp. of 400 °C and exposed to a convection environment at 40 °C with h= 120 W/m2. °C. Calculated the thermal conductivity that will just cause an insulation thickness of 0.2 mm to produce a “critical radius”. How much of this insulation must be added to reduce the heat transfer by 75 percent from that which would be experienced by the bare wire? Example 6 So the addition of 25 percent Heat Source Systems Situation: The system generated heat internally. Confine our discussion to 1D system (the temp. is a function of only 1 space coordinate) which is: 1)Plane Wall 2)Cylinder 3)Hollow Cylinder 1) Plane wall with heat sources Consider: The plane wall with uniformly distributed heat sources. The thickness of the wall in the x direction is 2 L Assumed: 1)The heat flow as 1D 2)The heat generated per unit volume is 3)Thermal conductivity, k does not vary with temp. * From steady-state 1D heat flow with heat sources For the boundary conditions (The temp. on either side of the wall) Integrated * equation with the boundary condition. So, the general solution become; 1) Plane wall with heat sources General solution C1 = 0 Because the temp. must be the SAME on each side of the wall. C2 = T0 The temp. T0 at the midplane (x=0) The solution obtain the temp. distribution OR “Parabolic distribution” OR 1) Plane wall with heat sources Midplane temp. T0 ?? (Obtained through an energy balance) At steady state conditions: The total heat generated = The heat lost at the faces From parabolic distribution : So that Differenced to get the temp. gradient at the wall, dT/dx 1) Plane wall with heat sources Simplify steady state condition become Midplane temp. T0 The same result for midplane temp. could be obtain by substituting into this equation (The temp. distribution): 2) Cylinder with heat sources Consider: Cylinder radius, R with uniformly distributed heat sources and constant thermal conductivity. Assumed: The cylinder is sufficiently long so that the temp. as function of radius only. The appropriate differential equation obtained by neglecting the axial, azimuth and time dependent term From steady-state 1D heat flow in cylinder coordinates with heat sources For the 1st boundary conditions At steady state conditions: The total heat generated = The heat lost at the surface 2) Cylinder with heat sources 2nd boundary conditions (The temp. function must be continuous at the centre of the cylinder), so could specify that From steady-state 1D heat flow in cylinder coordinates with heat sources Rewrite Note that : Substitute: Integrated 2) Cylinder with heat sources ** * Integration yield and From 2nd boundary condition * Thus, From 1st boundary condition ** Thus, The final solution for the temp. distribution is then (substitute C1 & C2) Or Dimensionless form 2) Cylinder with heat sources The final solution for the temp. distribution is then (substitute C1 & C2) Where T0 is the temperature at r = 0. So, the temp. distribution become: 3) Hollow cylinder with heat sources For hollow cylinder with uniformly distributed heat sources, the boundary condition would be The general solution same with cylinder Used boundary condition to get C1 and C2 Where the constant, C1 given by Basic steps involved in the solution of heat transfer problems Example 7 Example 8 Heat is generated uniformly in a stainless steel plate having k = 20 W/m.oC. The thickness of the plate is 1.0 cm and the hat generation rate is 500 MW/m3.If the two sides of the plate are maintained at 100 and 200 oC, respectively, calculate the temperature at the center of the plate. Thermal Contact Resistance Situation: 2 solid bars brought into contact, with the sides of the bars insulated so that heat flow only in the axial direction. The material may have different thermal conductivities, but if the side are insulated, the heat flux must be the same through both materials under steady-state conditions. The temp. drop at plane 2 (the contact plane between 2 material) because of “Thermal Contact Resistance” An energy balance on the 2 materials: Thermal Contact Resistance Where, Thermal Contact Resistance This factor extremely important in a no. of application because of the many heat transfer situations involve mechanical joining of 2 materials. Contact Coefficient Thermal Contact Resistance Physical mechanism Examining a joint in more detail Concept: No real surface is perfectly smooth and actual surface roughness is believed to play a central role in determining the contact resistance. There are 2 principle contributions to the heat transfer at the joint: 1) The solid-to-solid conduction at the spots of contact 2) The conduction through entrapped gases in the void space created by the contact 2nd factor is believed to represent the major resistance to heat flow because thermal conductivity of the gas is quite small compare of solid Thermal Contact Resistance So, designating the contact area, AC and the void area, AV, the Heat across the joint may write as: : Thickness of the void space : Thermal conductivity of the fluid which fills the void space : Total cross-sectional area of the bars Contact Coefficient Flow Assignment 2 Book: J.P. Holman 1)2-1 2)2.2 3)2-5 4)2-6 5)2-7 6)2-8 7)2-9 8)2-17 and 2-18 9)2-26 10)2-62 Tutorial 1 Book: J.P. Holman 1) 2-4 2) 2-13 3) 2-19 4) 2-20 5) 2-21 6) 2-22 7) 2-23 8) 2-27 9) 2-31 10) 2-60 Assignment 3 Book: J.P. Holman 1)2-30 2)2-55 3)2-117 Tutorial 2 Book: J.P. Holman 1)2-44 2)2-45 3)2-46