Corsica University

advertisement

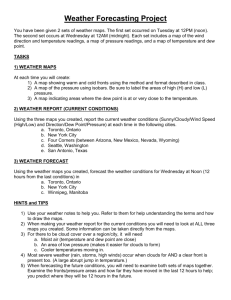

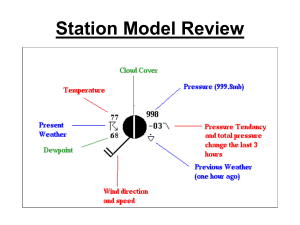

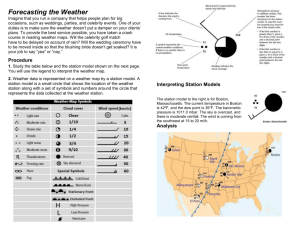

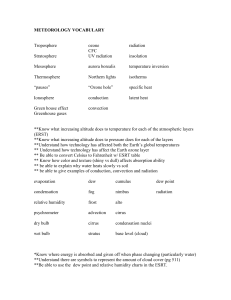

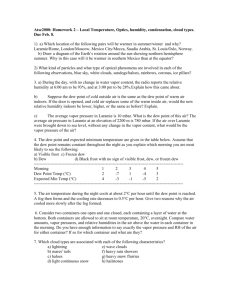

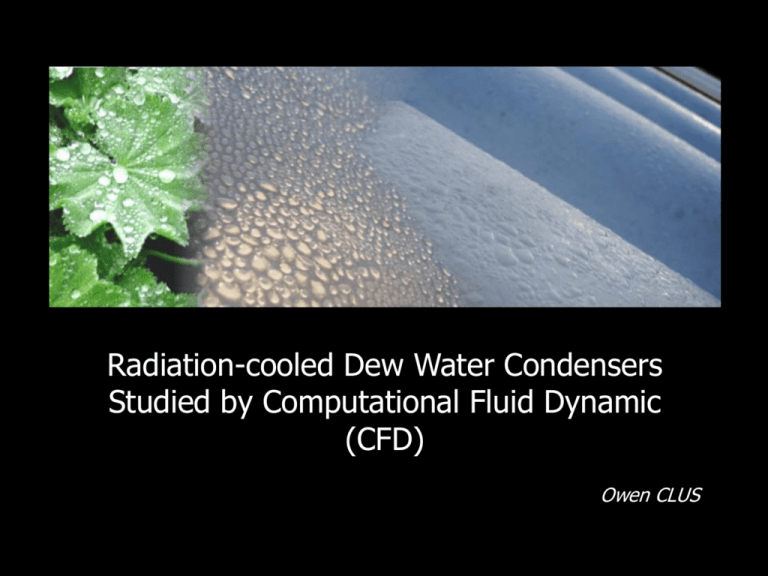

Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) Owen CLUS 2006 European PHOENICS User meeting Wimbledon, 30th Nov. 1st Dec., 2006 Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) Radiation-cooled Dew Water Condensers Owen CLUS Université de Corse Studied by Computational Fluid Dynamic Jalil OUAZZANI Arcofluid Marc MUSELLI Université de Corse (CFD) Vadim NIKOLAYEV Girja SHARAN Daniel BEYSENS International Organization For Dew Utilization CEA/CNRS-ESPCI Paris Indian Inst. of Management, Ahmedabad CEA/CNRS-ESPCI Paris Atmospheric vapour harvesting by radiative cooling Researches for condensing atmospheric vapor as alternative water resource in arid areas without energy supplying Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) Atmospheric vapour harvesting by radiative cooling Innovative formulations cheap polymers Radiative budget - 70 W/m² LDPE, paint Surface 3 to 8°C below Tambient Researches for condensing atmospheric high IR emissivity vapor as alternative water resource without CLEAR SKY energy supplying Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic polymer basis (CFD) Insulation substrate ROOF GROUND Radiative Filler Pilots, Prototypes FRANCE FRANCE Experimental prototypes 1 m² Radiation-cooled Dew Water Condensers 30 m² 10 L / night 1 m² 0.6 L / night Studied by Computational Fluid Dynamic of (CFD) rain 15 m² 7 L /Dew night= 30 % INDIA Quantitative systems CROATIA 800 m² 300 L/ night CFD simulations of radiative condensers The CFD tool has been developed for helping decision and technical choices before implementing these huge systems without Radiation-cooled Dew Water Condensers preliminary empirical tests Studied by Computational Fluid Dynamic (CFD) Radiative condenser as thermal machine Radiative cooling Wind flow Condenser shape and thermal properties condensation in weak wind, limit free / forced convection Radiation-cooled Dew Water Condensers variability of data Studied by Computationalmeteorological Fluid Dynamic Free induces long time convection (CFD) outdoor experiments heating forced convection heating α r R no description for complex shapes without empirical corrections Radiative cooling inclusion in CFD Specific radiative cooling for each shape dR = (εs,θ σTamb4 – εr σTrad4) dΩ angular sky emissivity s, 1 1 s isotropic radiator emissivity εr = 0.94 1 bcos Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic SKY (CFD) εm dΩ 0.94 εs,θ θ α 1 Radiative cooling inclusion in CFD FORTRAN tool for integrating radiative budget on various shapes angular integration dissipation law included in Phoenics computation: ER =clairf(T) BILANS RADIADIFS (en ciel nocturne à 15°C) Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) Puissance dissipée (W/m²) Radiative budget (W/m²) 0 plan 0.0° -10 plan 30° cone 20° -20 cone 30° -30 cone 40° -40 -50 -60 -70 -80 5 10 15 Température Foil (°C) (°C) Radiator Temp. 20 Radiative condenser described in CFD 3 Dimensions virtual reality description Convective heating for every shapes and for various wind speeds is given by Iterative calculation Radiative cooling power ER is dissipated for each radiator cell. TRAD (one phase model as Dew in dry air) Radiation-cooled Water Condensers Studied by Computational Fluid Dynamic LOG Wind Volumes Grid (CFD) Profile ER P T ρ u v w Radiative cooling Shape Materials Convective heating Cone-shaped condenser simulation Wind speed variations for 0.25 ; 0.5 ; 1.0 and 2.0 m/s at 10 m side tilt variations for 50 ; 40 ; 35 ; 30 ; and 25 Deg. Radiation-cooled Dew Water Condensers Studied by Computational WIND Fluid Dynamic (CFD) PROFILE Cone-shaped condenser simulation Radiation-cooled Dew Water Condensers 30° tilted Studied by Computational FluidMore Dynamic efficient (CFD) Cone-shaped condenser prototype (France) 30° tilted 7.3 m², Φ 3 m Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) 3.160 L water / night 38 % more water than on the 1m² planar condenser CFD simulations validation Comparison of simulated efficiency with physical measurements on real system on 5 various condensers from 0.16 to 255 m² installed during long period Radiation-cooled Dew 1 m² planar condenser is the Water referenceCondensers because always set by up simultaneously nearby each Studied Computational Fluidsystem Dynamic (CFD) Radiative condenser as thermal machine 0.16 m² (A) 1 m² REF 30 m² 7.3 m² Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) (B) (B) (C) (D) (E) 3 ridges 255 m² Comparison “Temperature gain” / “Dew gain” Surface Temperature TCOND, Simulations rough results Radiation-cooled Dew Water Condensers Non quantitative Studied by Computationalcomparison, Fluid Dynamic the cooler (CFD) the surface, the better the dew yield. Comparison “Temperature gain” / “Dew gain” <DT0> <DewX/dew Ref> Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) 1 m² 30° tilted planar 0.16 m2 PMMA plate 30 m², 30° tilted planar 7.32 m² cone 3 ridges, 255 m² 1.00 0.65 1.05 1.40 1.15 1.00 0.68 0.91 1.38 0.81 “Cooling power” or “temperature gain” related with Ta and 1 m² REF: Tcond Ta T0 TRe f Ta “Dew gain” related to 1 m² REF condenser water volume. H COND H 0 H REF Comparison “Temperature gain” / “Dew gain” <DT0> <DewX/dew Ref> Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) 1 m² 30° tilted planar 0.16 m2 PMMA plate 30 m², 30° tilted planar 7.32 m² cone 3 ridges, 255 m² 1.00 0.65 1.05 1.40 1.15 1.00 0.68 0.91 1.38 0.81 2 “Cooling power” or 1“temperature m² 30° 0.16 m gain” related with Ta tilted and 1 m² REF: PMMA Tcond T0 TRe f <DewX/dew Ref> <DT0> Ta 1.00 Ta 1.00 0.65 0.68 “Dew related REF 30 m², gain” 30° 7.32 m² to 13m² ridges, tilted cone 255 m² condenser water volume. H COND1.15 H (mm) 0.91 1.38 H REF0.81 1.05 1.40 Comparison “Temperature gain” / “Dew gain” <DT0> <DewX/dew Ref> Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) 1 m² 30° tilted planar 0.16 m2 PMMA plate 30 m², 30° tilted planar 7.32 m² cone 3 ridges, 255 m² 1.00 0.65 1.05 1.40 1.15 1.00 0.68 0.91 1.38 0.81 2 “Cooling power” or 1“temperature m² 30° 0.16 m gain” related with Ta tilted and 1 m² REF: PMMA Tcond T0 TRe f <DewX/dew Ref> <DT0> Ta 1.00 Ta 1.00 0.65 0.68 “Dew related REF 30 m², gain” 30° 7.32 m² to 13m² ridges, tilted cone 255 m² condenser water volume. H COND1.15 H (mm) H REF0.81 0.91 1.38 1.05 1.40 Conclusion INDIA Little set of data is needed to conclude the validation of the program This program has been advantageously used in Dew factory project for orientation and yields prospective Next step is to develop a two phases dew condensation simulation for more accurate quantitative results Radiation-cooled Dew Water Condensers Studied by Computational Fluid Dynamic (CFD) Owen CLUS CONTACT : http://www.opur.u-bordeaux.fr/