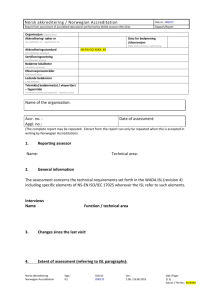

Report from technical assessor - 17025 (NA-S2c)

advertisement

Norsk akkreditering / Norwegian Accreditation Dok.id.: D00369 Report from technical assessor - 17025 (NA-S2c) Rapport/Report Organisasjon Organization Akkreditering- søker nr Dato for bedømming /observasjon Accreditation no. –application no. Date of assessment / witnessing Akkrediteringsstandard NS-EN ISO XXXX: XX Accreditation standard Bedømte lokaliteter Locations assessed Observasjonsområder Witnessed areas Ledende bedømmer Lead assessor Teknisk(e) bedømmer(e) / ekspert(er) – fagområde Technical assessor(s)/expert(s) – technical area The complete report may be distributed. Extrac from the report can only be distributed when this is accepted in writing by Norwegian accreditation. 1. Reporting assessor Name: 2. Technical area: General information Initial visit Extraordinary visit Re-assessment Surveillance Extension of scope during visit Full assessment Document review Extension of scope without visit Other (specify) Personnel interviews: Name 3. Function / technical area Recommendation 3.1 – Recommendation regarding accreditation/renewal: 3.2 – Recommendation regarding changes/extension of accreditation scope: Extension is recommended for: Internal method id: Method: Norsk akkreditering Norwegian Accreditation Sign.: ICL Object: Dok.ID: D00369 Ver.: 14.02 / 22.09.2015 Side /Page: 1( 6) Saksnr / File No.: XX/XXXX The following changes are recommended (Changes should be given in bold): Internal method id: Method: Object: No changes in scope required: 3.3 – Recommendation regarding change of the responsible for validation, when relevant (valid for flexible scope): 4. Major changes since the last visit (if any): 5. Extent of assessment (The numbers are references to the paragraphs in ISO 17025) Text in italic may be removed before the report is submitted to the lead assessor. 4 4.1 Management requirements Organization (Evaluation of the competence to the technical management) Non-conformity no: 4.2 Management system (Assess the availability of authorized documents in the laboratory. Are the personnel familiar with relevant documents in the management system?) Non-conformity no: 4.3 Document control (Are controlled documents and forms in use in the laboratory? Are the last versions in use? Use of uncontrolled documents observed?) Non-conformity no: 4.4 Review of requests, tenders and contracts (Are contracts documented. Do contracts clearly describe the service provided? Do contracts have any information about limitation in the methods, if relevant?) Non-conformity no: 4.5 Subcontracting of tests and calibrations (Have the client accepted the use of subcontractors?) Non-conformity no: 4.6 Purchasing services and supplies (Labelling of chemicals, regents and consumer goods included initial inspection) Non-conformity no: Norsk akkreditering Norwegian Accreditation Sign.: ICL Dok.ID: D00369 Ver.: 14.02 / 22.09.2015 Side /Page: 2( 6) Saksnr / File No.: XX/XXXX 4.9/4.11 Control of nonconforming testing and/or calibration work / Corrective action (Have relevant non-conformities been registered? Do they perform technically acceptable root cause analysis? Have analysis of consequences of NC-work been performed? Are evaluations done in connection with corrective actions satisfactory?) Non-conformity no: 4.13 Control of records (Registrations, handling of raw data, changes of raw data, traceability in registrations and archives. For vertical audit, specify the sample number/ journal number/ technical area, parameter and object) Non-conformity no: 5 5.2 5.2.1 Technical requirements Personnel Training (Are the CVs clear and updated? Training and qualification of personnel, new employees and after long absence) Non-conformity no: 5.2.2 Maintenance of competence (Including testing experience, retraining, requalification if relevant ) Non-conformity no: 5.2.4 Job descriptions Non-conformity no: 5.3 Accommodation and environmental conditions Non-conformity no: 5.4 5.4.1 Test and calibration methods and method validation General (Evaluate if the laboratory has appropriate methods and procedures ) Non-conformity no: 5.4.2 Selection of methods (Please give information about types of methods used for testing/calibration. Are the latest valid editions of standard methods in used? Are routines to ensure that the client orders correct analysis implemented) Non-conformity no: 5.4.3/5.4.4 Laboratory-developed methods/Non-standard methods Norsk akkreditering Norwegian Accreditation Sign.: ICL Dok.ID: D00369 Ver.: 14.02 / 22.09.2015 Side /Page: 3( 6) Saksnr / File No.: XX/XXXX (Updated plans for introduction of laboratory developed methods, if relevant? Are use of non-standard methods agreed on with the client?) Non-conformity no: 5.4.5 Validation of methods (Evaluate procedures for validation, conduct and reporting of validation. Are modifications in the standard methods, if any, validated and documented? Are modifications identifiable in the internal method description?) Non-conformity no: 5.4.6 Estimation of uncertainty of measurement (If the uncertainty is based on metrological and statistically basis: Have all relevant contributions been taken into consideration? Are the calculations documented in a controlled document? If the uncertainty is calculated from experimental (validation) data: Does the reported uncertainty represent the total uncertainty and the whole measurement range? Are the important contributions to the uncertainty identified and evaluated for their importance? Are the calculations documented in a controlled document? If it is not required to calculate the uncertainty (e.g. NDT, sampling, taxonomy): are the contributions to uncertainty identified and evaluated for their importance?) Non-conformity no: 5.4.7 Control of data (Calculations, LIMS, excel, data transfer, use, registration, maintenance and validation) Non-conformity no: 5.5 Equipment (Maintenance of equipment, logbooks, instrument register, labelling of equipment, calibration and control) Non-conformity no: 5.6 Measurement traceability (How does the laboratory achieve traceability for the methods? Calibration and control of equipment, use of reference materials/standards, calibration certificate/standards, calibration program ) Non-conformity no: 5.6.3 Reference standards and reference materials (Reference standards, reference materials, intermediate checks, transport and storage) Non-conformity no: 5.7 Sampling (If relevant) Non-conformity no: 5.8 Handling of test and calibration items (Does the laboratory make registrations if there are any irregularities when receiving a sample? Identification of objects /samples, possibility of making anonymousness of test objects, storage and disposal) Non-conformity no: Norsk akkreditering Norwegian Accreditation Sign.: ICL Dok.ID: D00369 Ver.: 14.02 / 22.09.2015 Side /Page: 4( 6) Saksnr / File No.: XX/XXXX 5.9 Assuring the quality of test and calibration results (How does the laboratory assure the quality of the results such as by use of proficiency testing, CRM, RM, control charts etc? Does the laboratory participate in PT programmes covering the whole scope? Is the participation sufficient? Are the results satisfactory? Has the laboratory implemented a procedure for evaluation of its own results? Have the laboratory records from trend analysis and evaluations of any systematic errors?) Non-conformity no: 5.10 Reporting the results (Is the report precise and clear? Are the units of measurement correct? Is all information that is required in a test report/calibration certificate registered? Are the results from subcontractors identified as so? Is the use of the accreditation mark/reference to accreditation satisfactory? Are non-accredited results/accredited results marked satisfactorily? Simplified reporting: Is the report according to the agreement with the client?) Non-conformity no: 5.10.5 Opinions and interpretations (If relevant) Non-conformity no: Other requirement documents: NA-Doc 14 Rules for use of Norwegian Accreditation’s (NA’s) logo and for references to NA’s accreditation Non-conformity no: NA-Doc 26a Requirements for calibration and control of balances in accredited testing laboratories Non-conformity no: NA-Doc 26b Traceability requirements of the temperature measurement for accredited laboratories Non-conformity no: NA-Doc 26c Requirements for calibration and control of volumetric equipment for accredited testing laboratories Non-conformity no: NA-Doc 50 Flexible scope for testing laboratories (If relevant. Is the flexibility used? If yes, is there a log of changes and is it acceptable? Are the validation reports satisfactory? Impressions after interview with the responsible person(s) for the validations) Norsk akkreditering Norwegian Accreditation Sign.: ICL Dok.ID: D00369 Ver.: 14.02 / 22.09.2015 Side /Page: 5( 6) Saksnr / File No.: XX/XXXX Non-conformity no: EA – 4/02 Measurement uncertainty in calibrations (If relevant, valid for calibration laboratories only) Non-conformity no: 6. Methods demonstrated and/or discussed Method id/parameter/object: Demonstrated of / Discussed with: 7. Follow up non-conformities from the last visit 8. Summary and conclusions 9. Next visit (Are there any subjects that should be specifically evaluated during the next visit, or specific personnel that should be present) The undersigned states that the content in the report is not in conflict with NA’s policy and practice. Date/Sign technical assessor Date/Sign lead assessor The organisation has the right to complain against the errors in the report. A complaint must be presented at the latest 3 weeks after the report has been sent from Norwegian Accreditation Norsk akkreditering Norwegian Accreditation Sign.: ICL Dok.ID: D00369 Ver.: 14.02 / 22.09.2015 Side /Page: 6( 6) Saksnr / File No.: XX/XXXX