Presentation - Damietta port authority

METHANOL IN OUR LIVES

Egypt Project

1.3 million tonne plant in

Damietta, Egypt

• EMethanex JV

Methanex (60%)

Egyptian Government JV

Partners ECHEM & Apicorp

(40%)

• Methanex will market 100%

Startup expected in 1H 2010

DAMIETTA

EMethanex Plant Site, July 2009

Mubarak Gas and Petrochemicals Complex, Damietta

Methanex’s Global Operations

•

•

Production Capacity (millions of tonnes)

•

•

•

•

Chile: 3.8

Trinidad: 2.1

New Zealand: 0.5-1.4

Egypt (60%): 0.8 (2010)

2008 Sales ~ 15% of global demand

•

•

•

•

2008 Revenues: US$2.3 Billion

Low-cost Waterfront Shipping Subsidiary:

~19 vessels

Employees: ~825

Shares listed: NASDAQ, Toronto, Santiago

Methanex Corporation Overview

Committed to Responsible Care

®

• 21 employees around the world dedicated to RC activities

Commercial Offices:

• Hong Kong, Brussels, Dallas, Santiago

• Tokyo, Shanghai, Seoul, Billingham, Dubai

Shipping Subsidiary: Waterfront Shipping

• Manage fleet of ~20 vessels

What is Methanol ?

METHANOL

(Methyl Alcohol)

Clear, colorless liquid

Made up of carbon, hydrogen and oxygen

Chemical formula

CH3OH

How is Methanol produced ?

Where is Methanol used ?

Methanol is...

Produced from natural gas and coal

Diversified end uses

Traditional Uses

(Mature Markets)

Formaldehyde Acetic Acid

MDF, Plywood Fleece, Adhesives, Paints

Emerging Energy Uses

(High Growth Potential Markets)

Fuel Blending

DME

(dimethyl-ether)

Dimethyl Methyl Chloride

Terephthalate Silicones

Recyclable plastic bottles

The Methanol House

Properties of Methanol

Flammable, burns with clear, low heat flame

Difficult to see during daylight

Soluble in water, miscible in alcohol, ether and to most organic solvents.

Low solubility in fats and oils.

Concentrations of methanol in water above 25% are flammable

Flash point ( ° C): 11 -12

Lower Explosive Limit (LEL) (%): 6

Upper Explosive Limit (UEL) (%): 36

Autoignition Temp ( ° C): 385

Boiling Range( ° C): 63.9 – 65

Properties of Methanol

Melting Range ( ° C): -97.8

Specific gravity (water=1): 0.79 @ 20 ° C

Biodegrades quickly in small amounts

Readily absorbed into the body

Poisonous in liquid or vapours state

Toxic: danger of very serious irreversible effects through inhalation, contact with skin and if swallowed

Methanol Handling

Remember Methanol is:

NFPA Methanol

Toxic Flamable

3 : Risk of flammability: You can ignite at ambient temperature

1 : Risks to health: Slightly dangerous

0 :: Risk of reactivity: Stable

Methanol Handling

Full-scale Pool Fire test carried out at Spadeadam test site in

Cumbria, UK on 9 March 1993

Flame geometry and thermal radiation from methanol pool fires in 5.85 metre diameter bunds. Pool being filled

Methanol Handling

Ignition!

Methanol Handling

Colorless flame - just a heat haze. Wind speed was 4.4 metres/second (10 mph) ambient temperature was 4.5

° C, pressure 981 millibar

Methanol Handling

Safety precautions

No smoking

Vehicular access

Intrinsically safe equipment

Grounding all equipment, pumps, tanks, pipes,vessels, filters

Methanol Handling

Fire Fighting/Explosion Hazard

May be violently or explosively reactive

Severe fire hazard when exposed to heat, flame and/or oxidizers

Vapor may travel a considerable distance to source of ignition

Extinguishing Media

Alcohol stable foam

Dry chemical powder

Carbon dioxide

Water spray or fog - Large fires only.

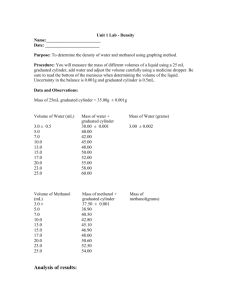

EMethanex Plant Layout

V-064

V-065

2 Blinded

4” end flange to

Lever Operator

V-040 V-039

H-029

14” Blinded

H-030

V-042

V-043

V-044

Preparing temporary 12`` to

6``spool which will using for flushing direct to field

3 Blinded 6” end flange

M-002 has leak from the flange to check it you have to open the head of header and its Sperry nozzle is malefaction

V-061

H-018

V-014

V-013

H-006

H-028

V-041

V-066

V-045

H-031

V-048

M-005

M-004

V-049

M-003

V-050

V-051

M-002

V-052

M-001

V-053

V-054

Turbo

Gen.

A/B

Main

Sub-

Station

V-038 V-037

H-027

FIRE FIGHTING SYSTEM

HYDRANT MAIN RING

Updated: 14/01/2010

V-036 V-035

H-026

1TK-2602B 1TK-2602A

V-067

1P-2602

1P-2603

V-046 V-047

M-006

1TK-2501

M-007

1TK-2601B

M-008

V-060

1TK-2601A

V-059 V-033 V-032

H-025

V-034

H-024

H-023

H-00

Fire Hydrant

M-000

V-00

Fire Water Monitor

Valve Close Position

V-00

Valve Open Position

V-00

Valve End Blinded

Blinded Lever Operator Monitor

V-016

Process Unit 1

M-017

M-009 1SU-5504

Process Unit 1

M-016

M-015

Reformer

M-014

Chain & lock

M-010

V-058

V-057

M-011

6” blind before Deluge system of

Oil skid for Syn. Gas compressor

H-020

V-015

ASU-Unit 1

V-017 V-018

M-013

Aux

Boiler

A/B

H-007

V-00

V-056

M-012

V-055

H-019

V-027

V-019

Cooling Tower

V-031

H-022

4” Blinded end flange

The Port Fence

V-029

H-021

V-030

V-028

Flare Unit

V-00

Storm Water Pond

1P-5507/8

V-020 V-021

H-009

V-022

Flushed line and under fire header Pressure

H-013 H-014

H-010

There are two had wheel is broken

ECHEM

Area

V-024

V-023

H-015

H-012

Demi

Tank

Potable

Tank

Filtered

Tank

Jockey Pump

Run at 175 psi

V-00 V-00

V-006

V-005

H-016

H-001

V-025

V-026

H-017

V-001 V-002 V-003

V-004

Control

Room

Water Treatment

H-011

V-009

Metering

Station

H-005 H-002

H-004 H-003 V-008

V-012 V-011 V-010

V-062

V-007

There is one hand wheel is broken

H-032

H-033

Methanol Handling

How do we detect Methanol?

Detector tubes

Electronic Instruments

Absorbent tubes

Biological Monitoring

Process Side: Safe Methanol Handling

Closed sampling / dip / temperature measurement on the Methanol

Storage Tanks

Routine samples using closed cylinders

Tandem seals on all methanol pumps

Safe Methanol Handling

Personnel and Environmental protection

Process side

AAAF foam for methanol fire fighting

Methanol tanks fully bunded and controlled drainage

Methanol vapors recovery system on all methanol tanks and from the ships

Process Side: Safe Methanol Handling

Methanol Ship Loading

•Loading arms provided with an Emergency Release System

•Spill and drains containment pumped back to the plant

•Foam-water monitors

•Grounding and interlock, and others

Methanol Truck Loading

•Automatic stop logic if high truck level

•Foam-water monitors

•Dedicated tanks

•Safety induction to the driver and certification

•Grounding and interlock

•Dip loading pipe , and others

Plant Fire Fighting System

Fire Water / Foam System.

1.

Filtered Water Tank used as fire water supply

2.

Fire Water Jockey pumps 1P-4401 A/B, Diesel pumps 1P-4402 A/B/C/D.

3.

Fire Water Jockey / Diesel pumps P&ID.

4.

WATER / FOAM DELUGE SYSTEM.

5.

Water Deluge SYSTEM.

6.

Heat detectors and Gas detectors

1.Dry Chemical Powder System

2.Fire truck (water, foam, dry chemical) and portable Extinguishers of various types at strategic locations

Firewater is supplied to the plant via a ring main system of piping.

The northern portion of the ring main protects the methanol storage tank area and the southern portion of the ring main protects the methanol production area, utilities, and buildings.

Firewater supply is from the Filtered Water Tank

Water / Foam Deluge System

Methanol Product Tanks 1TK-2602A/B

Water / Foam Deluge System

Water / Foam level operated Monitors

Tank Area Dike Protection

Foam monitor system jetty area