CHAPTER 10

Facilities Layout and

Location

McGraw-Hill/Irwin

Copyright © 2009 by The McGraw-Hill Companies, Inc. All rights reserved.

10-2

Issues in Facilities Design

Minimize investment in new equipment

Maximize production throughput rate

Utilize space most efficiently

Provide for the safety and comfort of employees

Maintain a flexible arrangement

Minimize materials handling cost

Facilitate the manufacturing process

Facilitate the organizational structure

10-3

Patterns of Flow

Straight line flow

U flow

L flow

Serpentine flow

Circular flow

S flow

(refer to Figure 10-1)

10-4

Six Horizontal Flow Patterns

10-5

Activity Relationship Chart

(Rel Chart)

Each pair of operations is given a letter to indicate

the desirability of locating the operations near each

other. The letter codes are:

A: Absolutely necessary

E: Especially important

I: Important

O: Ordinary importance

U: Unimportant

X: Undesirable

(refer to Figure 10-2 for an example.)

10-6

Activity Relationship Chart for

Meat Me Fast-Food Restaurant

10-7

From-To Chart

From-to charts are similar to the mileage

charts on roadmaps. They can show:

Distances separating pairs of work centers

Numbers of materials handling trips between

pairs of work centers

Materials handling costs between pairs of work

centers

(See Figure 10-3 for an example of a From-to distance

chart.)

From-To Chart Showing Distances

Between Six Department Centers

(Measured in Feet)

10-8

10-9

Types of Layouts

Fixed Position Layouts – suitable for large items

such as airplanes.

Product Layouts – work centers are organized

around the operations needed to produce a product.

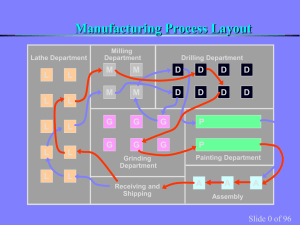

Process Layouts – grouping similar machines that

have similar functions.

Group Technology Layouts – layouts based on the

needs of part families.

(Refer to the examples in the next four figures)

10-10

Fixed Position Layout

10-11

Product layout

10-12

Process layout

10-13

Group Technology Layout

10-14

Computerized Layout Techniques

CRAFT. An improvement technique that requires the

user to specify an initial layout. Improves materials

handling costs by considering pair-wise interchange of

departments.

COFAD. Similar to CRAFT, but also includes

consideration of the type of materials handling system.

ALDEP. Construction routine (does not require user to

specify an initial layout). Uses REL chart information.

CORELAP. Similar to ALDEP, but uses more careful

selection criteria for initial choosing the initial department

PLANET. Construction routine that utilizes user

specified priority ratings.

10-15

Flexible Manufacturing Systems

An FMS is a collection of numerically controlled

machines connected by a computer controlled

materials flow system. These systems typically are

best for systems with moderately high output and

moderately high need for flexibility.

For low volume high variability systems, stand alone

systems are better, and for high volume, low

variability, fixed transfer lines are better. Refer to

Figure 10-21 to see the environments where FMS

systems are appropriate.

Figure 10-22 shows a typical FMS system.

The Position of FMS

in the Manufacturing

Hierarchy

10-16

10-17

A Typical Flexible

Manufacturing System

10-18

Advantages of the FMS

Reduced work-in-process inventories

Increased machine utilization

Reduced manufacturing lead time

Ability to handle different part

configurations.

Reduced labor costs

10-19

Disadvantages of the FMS

The main problem is cost. Systems cost

upwards of $10 million. They require

upgrading of other related systems (such as

the materials handling system) that can be

equally expensive. There are few cases

reported in the literature that show the

investment in FMS had a reasonable

payback period.

10-20

Facility Location

Goal is to find the optimal location of one or more new

facilities. Optimality depends on the objective used. In

many systems, the objective is to minimize some measure

of distance. Two common distance measures:

Straight line distance (Euclidean distance). The distance

between (a,b) and (x,y) is given by the formula:

( x a ) 2 ( y b) 2

Rectilinear Distance (as might be measured following

roads on city streets).

x a y b

10-21

The Single Facility Rectilinear

Distance Location Problem

Goal: locate n facilities to minimize the weighted

sum of rectilinear distances from the new facility

to existing facilities.

Solution: locate the new facility at the median

location of the existing facilities. This is

accomplished by taking the median location

component by component of existing locations.

10-22

The Gravity Problem

The objective is to minimize the weighted sum of

the squared Euclidean distances of the new facility

to the current facilities. It is an uncommon

problem but has a simple solution.

The optimal solution is that both the x and y

coordinates of the new facility are the ratio of the

weighted x and y coordinates of the existing

facilities divided by the sum of the weights.

10-23

The Straight Line Distance Problem

The objective is to minimize the weighted

sum of the straight line distances of the new

facility to the current facilities.

No simple algebraic solution method exists.

Finding the optimal solution requires an

iterative solution procedure that may begin

with the gravity solution.