ch7_sup_process

advertisement

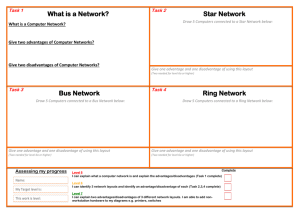

Manufacturing Process Layout Lathe Department L L L L L L L L L L Milling Department Drilling Department M M D D D D M M D D D D G G G P G G G P Grinding Department Receiving and Shipping Painting Department A A A Assembly Slide 0 of 96 Process (Job Shop) Layouts Equipment that perform similar processes are grouped together Used when the operations system must handle a wide variety of products in relatively small volumes (i.e., flexibility is necessary) Slide 1 of 96 Characteristics of Process Layouts General-purpose equipment is used Changeover is rapid Material flow is intermittent Material handling equipment is flexible Operators are highly skilled . . . more Slide 2 of 96 Characteristics of Process Layouts Technical supervision is required Planning, scheduling and controlling functions are challenging Production time is relatively long In-process inventory is relatively high Slide 3 of 96 A Product Layout In Out Slide 4 of 96 Product (Assembly Line) Layouts Operations are arranged in the sequence required to make the product Used when the operations system must handle a narrow variety of products in relatively high volumes Operations and personnel are dedicated to producing one or a small number of products Slide 5 of 96 Characteristics of Product Layouts Special-purpose equipment are used Changeover is expensive and lengthy Material flow approaches continuous Material handling equipment is fixed Operators need not be as skilled . . . more Slide 6 of 96 Characteristics of Product Layouts Little direct supervision is required Planning, scheduling and controlling functions are relatively straight-forward Production time for a unit is relatively short In-process inventory is relatively low Slide 7 of 96 Comparison of Product and Process Layouts Product Description Type of process Product Demand Volume Equipment Process Sequential arrangement of activities Functional grouping of activities Continuous, mass production, mainly assembly Standardized, made to stock Stable High Special purpose Intermittent, job shop, batch production, mainly fabrication Varied, made to order Fluctuating Low General purpose Slide 8 of 96 Comparison of Product and Process Layouts Product Workers Inventory Storage space Material handling Aisles Scheduling Layout decision Goal Advantage Limited skills Low in-process, high finished goods Small Fixed path (conveyor) Narrow Line balancing In-l,ine, U-type Equalize work at each station Efficiency Process Varied skills High in-process, low finished goods Large Variable path (forklift) Wide Dynamic Functional Minimize material handling cost Flexibility Slide 9 of 96 Cellular Manufacturing (CM) Layouts Grouping of machines in cells Each cell results in the production of particular part family. Similar parts are identified and grouped together. Similarity can be either in shape,size or in manufacturing process Operations required to produce a particular family (group) of parts are arranged in the sequence required to make that family Used when the operations system must handle a moderate variety of products in moderate volumes Slide 10 of 96 Part families Part families with similarity in manufacturing process Part families with similarity in shape Slide 11 of 96 Original Process Layout Assembly 4 6 7 8 5 2 A B 12 10 3 1 9 C 11 Raw materials Slide 12 of 96 Part Routing Matrix Parts 1 2 A B C D E F G H x x 3 Machines 4 5 6 7 8 9 10 11 12 x x x x x x x x x x x x x x x x x x x x x x x x x x x x Figure 5.8 Slide 13 of 96 Reordered Routing Matrix Parts 1 2 4 Machines 8 10 3 6 A D F C G B H E x x x x x x x x x x x x x x x x x 9 5 x x x x 7 11 12 x x x x x x x x x Slide 14 of 96 Revised Cellular Layout Assembly 8 10 9 12 11 4 Cell 1 Cell 2 6 Cell 3 7 2 1 3 5 A B C Raw materials Slide 15 of 96 Automated Manufacturing Cell Source: J. T. Black, “Cellular Manufacturing Systems Reduce Setup Time, Make Small Lot Production Economical.” Industrial Engineering (November 1983) Slide 16 of 96 Characteristics of CM Relative to Process Layouts Equipment can be less general-purpose Material handling costs are reduced Training periods for operators are shortened In-process inventory is lower Parts can be made faster and shipped more quickly Equipment can be less special-purpose Changeovers are simplified Production is easier to automate Slide 17 of 96 Flexible Manufacturing Systems (FMS) FMS consists of numerous programmable machine tools connected by an automated material handling system and controlled by a common computer network FMS combines flexibility with efficiency FMS layouts differ based on variety of parts that the system can process size of parts processed average processing time required for part completion Slide 18 of 96 Full-Blown FMS Slide 19 of 96