Super Therm - Arizona Superior Coatings

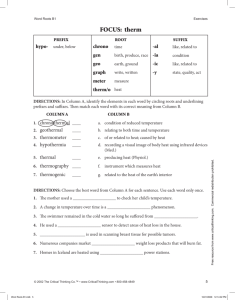

advertisement

By: Jim Williams President Arizona Superior Coatings P.O. Box 385 Vail, AZ 85641 (520) 647 - 7672 jim@arizonasuperiorcoatings.com www.arizonasuperiorcoatings.com SUPER THERM® SP SEAL COAT HSC 1000™ (hot surface coat) iSTUCCO SYSTEM SUPER THERM® Thermal Barrier Ceramic Coating SUPER THERM® is a ceramic based, water borne, thermal barrier coating that is designed to block and reflect heat that increases energy and maintenance cost. As the only ceramic coating developed in cooperation with NASA, SUPER THERM® is the most effective, durable, and long lasting ceramic coating on the market. 30% It has 4 unique ceramic compounds which : Block 95% of Solar Heat Insulate 40% Infrared Ultraviolet Visable Light 57% 3% Heat Sources from the Sun 92% Visible Light 99.5% Infrared 99% Ultraviolet Properties of Cool Roofing Materials Definitions • Solar Reflectivity – Amount of incoming solar energy a material reflects (usually in %) • Emissivity – Amount of energy a material emits due to its own heat and temperature (usually in %) sun reflected emitted roof • Fear of glare Super Therm® produces diffused reflections, not secular reflections secular diffuse Nippon Paint Factory Roof Insulation 14 Residential Home Little Rock, Arkansas Heat Loss Captured by Infrared Camera BEFORE Application of Super Therm® 15 UNIQUE CERAMIC COMPOSITION Blend of four different ceramics that block all windows of heat transfer. Other ceramic coatings only contain glass hollow spheres that reflect visual light when clean but absorb and transfer other windows of heat. Only ceramic coating rated as an insulator by BOCA (Us Building Code). Includes various resins, including urethanes for durability and longevity. Protection from the elements Rain Moisture Humidity Dampens sound waves 68% reduction Super Therm™ Super Therm® is rated as a true insulator by BOCA (US Building Code) R19 equivalent rating 10 mil dry Super Therm™ = 6” – 8” ASHRAE 90.1 CODE COMLIANCE TESTING REQUIRED TO PROVE THE RE VALUE A. ASTM C 236-89 “ Standard Test Method for Steady-State Thermal Performance of Building Assemblies by Means of a Guarded Hot Box.” B. ASTM 1269 “Differential Scanning Calorimeter” ASTM E 1461-92 “Thermal Diffusivity.” Super Therm® has a “U” ( Thermal Flow) Value of 0.052. Super Therm® is (1/RE) = 0.052 Thermal Flow. ASHRAE 90.1 Compliance Varrience cannot exceed 0.061 for Thermal Flow. Super Therm® falls within the ASHRAE 90.1 Compliance Rating and is acceptable. Class A Fire Rating Super Therm™ Prevents Mold and Mildew USDA Approved Certified Water Barrier (ASTM D 7088, ASTM D 6904) Super Therm™ Environmentally Friendly (24 grams per liter VOC) Very Long Life Expectancy 20 Years Extraordinary elasticity Passed ASTM E1737 Roof Insulation Topside Underside Concrete Insulation walls floors Sound proofing Ice Machines Elevators Building Envelope Air Conditioning & Ducting AC Units AC Ducting Chicago Bridge & Iron Company Beaumont, Texas Before Super Therm® Application Saw Tooth Section Built 1937 39 After Super Therm® Application 187,000 Sq.Ft. of Metal and 82,000 Sq.Ft. of Tar & Gravel Nissan Motor Co. Ltd. Yokahama, Japan 200,000 Sq. Meters Before 40 After Tucson Intl. Airport Tucson, AZ Super Therm® was applied to Central Plant West Concourse East Concourse Wash Bays Note: A power wash and thorough cleaning was performed on all roof tops prior to application Tucson International Airport August 2009 Savings = $22,144 Chris Wilt - Senior Director Facility Development RESIDENTIAL HOME TUCSON, AZ 70 degrees Super Therm® was applied to Roof Top Front Porch Cover Back Patio Cover SP Seal Coat was used on all water channels and crickets All penetrations were sealed prior to Super Therm® 77 degrees BEFORE CIRCLE K TUSCON, AZ AFTER CIRCLE K TUCSON, AZ TRUMP INTERNATIONAL FT. LAUDERDALE, FL Super Therm® was applied to Concrete ceiling of lobby Concrete ceiling of parking structure under air conditioned space SANTA ROSA DUNES PENSACOLA, FL Bel-Air Condos in Austin, Texas SPI iStucco™ System Thermal Scan BEFORE iStucco™ System 48 ™ iSTUCCO System Before Ceramic Stucco Application iStucco After Super Therm® Frito Lay Trailer, KY Trailer Irvington Elementary School, KY Apartent Buildings And Hotel In Munich Germany 55 Residential Home Las Vegas, Nevada 56 ENERGY STAR Program Approved and accepted with Energy Star for saving energy. ASTM E 903-96 Reflectivity=80% Only 1% Reduction in Reflectivity over 3 Years (3% over 10 years) ASTM Testing B 117/D 1654 450 Hour Salt Spray (Fog) – Passed C 177 thermal conductivity testing – Passed C 236 (C236-89(1993)el) – Passed, our performed fiberglass by 148%. – Standard Test Method for Steady-State Thermal Performance of Building Assemblies by means of Guarded Hot Box. Testing for measuring R-values. C 411 High – Temperature Surface Performance – Passed D 412 Tensile strength – Passed – .041 thickness = 13,248 psi ASTM Testing cont’d… D 522 – Passed – Resistance to cracking on metal or rubber type materials. 1” (25mm)bend. ¼”(96mm)bend D 1653 Water Vapor Permeability – Passed D 1654 Salt spray (fog/weathering) – Passed – 2000 hours D 3273-82T D 3274 – Passed – Resistance to fungal growth or soil and dirt accumulation on paint film. Excellent (8 out of 9) D 4060 Abrasion Resistance – Passed E 84 Flame Spread / Smoke Developed – Passed – Class “A” Rating (or Class “1” or Class “I”) ASTM Testing cont’d… E84-89a Flame spread / Smoke Developed – Passed – “0” development – Flame Index “0”. Smoke Index “0” E96 water vapor transmission – Passed – less than .01 E 96 water vapor transmission – Passed – less than .01 E 903-96 Reflectance – Passed E 119 Structural Steel Fire curve – Passed – 25 minutes E 1269 Thermal penetration through a substrate by differential scanning calorimeter – Passed – blocking 99% of heat BTU conduction – TPRL ASTM Testing cont’d… E 1461-92 Laser flash technique conductivity diffusivity – Passed VTEC Laboratories review of test results – Letter stating RE19 TPRL lab test results show a bare metal plate allowing 367.20 BTU heat conduction. SUPER THERM® coated on metal plate allowed only 3.99 BTU heat gain. A 99% reduction in heat transfer after applying only one coat of SUPER THERM ® on test plate. G53 exposure to UV, elevated temperature and humidity Passed ICC Approval (International Code Councel) 0104 Passed – ID #21-25 Council that formally consolidates approvals for BOCA (Building Officials Code Administrators) – – – – – Section 723.2 Exposed installations, Thermal insulation Section 723.3 Concealed installations, Thermal insulation Section 803.2 Classification, Interior finish 1998 International Mechanical Code Section 604.3 Coverings and Linings, Insulation ICBO (International Conference of Building Officials) Passed ASTM E 84 For Flame Spread Passed ASTM C 411 for High Temperature for Surface Performance Passed ASTM C 177 for Thermal Conductivity (*SUPER THERM Specific) NASA NHB 8060.1B/C Test 1 Flammability testing – Passed “0” Burn, Class “A” rating – Passed NHB 8060.1C, Test 7 Toxic Off gassing – Passed “K” no Toxic off gassing – Passed “K” Rating for toxicity – Passed Tests performed at Marshall Space Flight Center Key Endorsements USDA • Passed – Environmentally safe and safe for use around animals – Approved for incidental food contact – Letter of Written Certification as Accepted by USDA from Manufacturer Underwriters Laboratory Inc. • Approved Factory Mutual Approval • • Passed - E - 108 Flame Spread over pitched roofing Tested and Approved for Roofing and all other Applications California Cool Roof Program • California Building Energy Efficiency Standards Florida Cool Roof Rebate Program • State approval for energy rebate Next Steps: 1. Call me directly: (520) 647 – 7672 2. Go to our website at: www.arizonasuperiorcoatings.com 3. Fill out the questionnaire and we will get back to you Arizona Superior Coatings LLC. Corporate Office / Applicator P.O. Box 385, Vail, AZ 85641 Office 520-647-7672 Sales – Jim Williams, John Montano, Frank Tainatongo, Doug Alley: Superior Performance Coatings, Inc. Phone (520) 647 - 7672 Email: jim@arizonasuperiorcoatings.com Website: www.arizonasuperiorcoatings.com