Impression material

advertisement

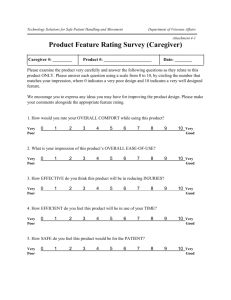

Impression materials أحمد عبد العزيز الحسين أخصائي تركيبات سنيه في وزارة الصحة األردنية محاضر غير متفرغ في جامعة العلوم والتكنولوجيا األردنية Ahmad Abdul Aziz Alhussien Prosthodontist at M.O.H Part time lecturer at J.U.S.T BSc , MSc, Jor. Board/ prosthodontics 1 • The function of an impression material is to make a negative copy of the oral tissue … that is poured to produce a positive replica for these tissues 2 Requirement of an impression material • Must be a semi-liquid material that will flow and adapt itself around the structure of interest. • It must set and harden into a solid ?? that is rigid enough “not too rigid” to be removed from the mouth without becoming deformed. • Copy details accurately • Dimensional stability after removal from the mouth • Appropriate working time (from the start of mix) • Appropriate time to harden in the mouth (setting time) • Bio-compatibility/Aesthetic, odor/taste • Chemically compatible with material used to pour cast or dies 3 Impression trays • Used to carry the impression material into the oral cavity • Can be – – – – metal or plastic Perforated or non perforated for edentulous or dentate pre-manufactured (stock trays) or custom-made (made in the lab. From resin). • Trays need to be rigid enough to support impression material. • For impression material to be retained in tray, tray maybe perforated, and adhesive spray can be used to enhance retention. 4 Variety of trays 5 • Cast replica of dental arch • Die replica of a single tooth (cut from a cast) 6 Classification of dental impression materials • Inelastic / Elastic • Mechanism of hardening 7 Impression material (rigid) Inelastic materials Setting mechanism Impression Cooling to mouth temperature compounds ‘Dental compounds’ Zinc-oxide eugenol (ZOE) Chemical reaction Impression Chemical reaction Cooling to mouth temperature plaster Impression wax 8 Impression materials (aqueous) Elastic material (hydro-colloid) Setting mechanism Reversible Cooling (Agar) Irreversible (Alginate) Chemical reaction 9 Impression materials (rubber) Elastic material (non- Setting mechanism aqueous) Polysulfides Polymerization reaction Condensation silicon Polymerization reaction Polyether Polymerization reaction Addition Polymerization reaction silicon 10 Inelastic impression materials (rigid) • Plaster of Paris (Type I gypsum) • Dental compound/impression compounds – Softened by heat and pressed against tissue before it hardens. Thermoplastic softens at 60°C, remains plastic at 45°C and becomes firm at mouth temperature. Used for primary impression • ZOE (Zinc oxide eugenol) – Other uses ??? • Impression wax Elastic impression materials (non-rigid) • Hydrocolloids • Elastomers (Rubber) 11 Hydrocolloids 12 Hydrocolloids • The colloid state represents a highly dispersed phase of fine particles within another phase, some where between solution and a suspension. • The colloid can exist as a viscous liquid known as a sol or a solid known as gel. • If the particles are suspended in water, the suspension is called a hydrocolloid (hydrosol, hydrogel • Hydrocolloids come in two forms: – Reversible agar – Irreversible alginate 13 Agar Composition of agar: Material Agar (seaweed extract) Percentage purpose 12-15% Colloidal particles as basis of the gel Potassium sulfate Borax 1% 0.2% Ensures set of gypsum materials Strengthens gel Alkyl benzoate water 0.1% Antifungal agent 85% Dispersing medium for the colloidal suspension 14 Properties • Flows well and adapts readily to hard and soft tissue contours • Accurate reproduction (hydrophilic nature), however, the impression need to be poured immediately. • Need to be stored in 100% humidity for short period of time if not poured immediately • Distortion is more likely to occur if impression not poured within an hour. 15 • Tear strength is not high. • If compressed it might rebound if compression is not too sever otherwise deformation occurs. • Material suffers from loss or gain of water: – Syneresis: a process by which the gel contracts and some of the liquid is squeezed out, forming an exudate on the surface. – Evaporation: loss of water which causes the material to shrink, and impression is distorted. – Imbibition: uptake of water, this will swell and distort the impression. 16 Clinical application • The use of agar requires special equipment consisting of hydrocolloid conditioner (has 3 water bath chambers) and water -cooled tray connected to a rubber hose that delivers water. • Usually used in lab for cast duplication • Agar is supplied in two viscosities, thick and thin (depending on the amount of agar). 17 • Preparing the material for impression: – Gel heated to 71-100°C, becomes liquid (sol) – Tray and agar syringe are liquefied in 8-12 minutes in boiling water in 1st chamber – 2nd chamber is used to store the agar at 6066°C. – 3rd camber kept at 45-47°C to temper agar before use to prevent burns. • Agar exhibits hysteresis, melting at 85 °C and solidifying from 3240 °C 18 Alginate • • • • Inexpensive Easy to manipulate Requires no special equipment Reasonably accurate Common uses: • • • • Diagnostic cast (study model) Preliminary impression for complete denture Partial denture framework Custom trays for fluoride or bleaching 19 Composition/setting rxn/ working time Material Percentage purpose Na, K alginate 15-20% Basis of the gel Ca sulfate dihydrate 14-20% Creates irreversible gel with alginate Potassium sulfate 10% ensures set of gypsum Trisodium sulfate 2% Retarder to control setting Diatomaceous earth 55-60% Filler to increase thickness and strength 20 Setting rxn/working time • Setting rxn occurs when the powder is mixed with water: Ca sulfate dihydrate + NaAlginate Ca alginate • Working time: total time from start of mixing to the final time at which an impression tray can be fully seated without distortion – Regular set: 2-3 minutes – Fast-set: 1.25-2 minutes • Setting time: elapsed time from the start of mixing until impression material becomes firm enough to resist permanent deformation. Regular set: 2-5 minutes, Fast set: 1-2 minutes 21 Setting rxn/working time • Controlling water temperature shortens or lengthens setting time • Changing P:L has adverse effect on materials property and strength • Allow extra 1-2 minutes, tear strength increases, and rebound from undercuts w/out deformation improves 22 Important considerations to ensure accurate impression • 2-4 mm bulk material in tray • Snap action removal from mouth • Allow extra 1-2 minutes after setting to improve tear strength • Stored in a moist environment to avoid loss of water and deformation • Disinfect in less than 10 minutes to avoid dimensional instability 23 Impression making • Fluff powder, wait 30 seconds for the dust to settle • Measure powder and water according to manufacturer instruction • Use spatula to stir water into powder to mix • Stir vigorously to create homogenous mix (45 seconds for regular, 30 seconds for fast setting alginate) 24 • Tray should cover all anatomical features • Utility wax can be added on tray borders to extend its coverage • Adhesive spray is used to prevent separation of alginate from tray. • Tray is loaded from posterior towards anterior • Moisten and smooth alginate • Posterior part of tray is seated first then anterior. • *tips to control gag reflex* 25 Alginate impression 26 Elastomers 27 Elastomers • Often called rubber materials since they have properties similar to rubber. • Clinical uses: – Bridges – Implants – Partial dentures complete dentures – Indirect esthetic restorations 28 Polymerization reaction • Involves formation of long-chain polymers and cross-linking of chains • General properties: – Not as sensitive to water as hydrocolloids – Have a certain amount of rebound, the highest is for addition silicon and polyethers, medium for condensation silicon and poorest for Polysulfides – Not wet well by water (hydrophobic) possible solution: surfactants 29 Polysulphides Dispensing & Composition • Supplied in two tubes as base and catalyst, equal lengths are mixed. Light, regular, heavy viscosities • Chemical composition of base: – 80% low-molecular-weight organic polymer containing mercaptan reactive groups (-SH), and 20% reinforcing agents: titanium dioxide, silica, zinc sulfide • Chemical composition of catalyst: – Lead dioxide or copper hydroxide 30 Setting reaction Mercaptan + lead dioxide polysulfide+H2O • The reaction is sensitive to temperature and moisture so increase in any will accelerate the setting. • Also sensitive to correct mixing ratio 31 Uses • Crown and bridge impressions • Partial and complete denture impressions Clinical considerations when used • Used with custom trays • Allow 2mm thickness • Use tray adhesive • Dry field 32 Properties of clinical interest • Setting time: 8-14 minutes • Higher tear strength than hydrocolloids • Accuracy improves if impression is poured within 30 minutes • very unpleasant taste and odor • Messy (orange solvent to remove stains) • Can be irritant to oral mucosa For all these reasons, Polysulfides have been largely replaced by other rubber materials 33 Silicon rubber Addition (A) silicon Condensation (C) silicon 34 Condensation silicon • Developed as alternative to Polysulfides • Has more desirable qualities in comparison: – Easy mix – Better taste and odorless – Shorter setting time (5-7 minutes) 35 Dispensing & Composition • • • • Two pastes, base and catalyst. Comes as light, medium, or heavy viscosity Base: dimethylsiloxane + filler (silica) Catalyst: suspension of stannous octoate + alkyl silicate 36 Setting rxn • Condensation reaction that produces ethyl alcohol as by product. The alcohol evaporates which causes dimensional instability. • The material continues to contract with time, so needs to be poured within minutes. 37 Addition silicon (PVS) • Desirable clinical qualities: – – – – – Dimensional stability Accuracy Clean Easy to mix No foul odor or taste the most expensive 38 Dispensing & composition • Light, regular and heavy viscosities and also putty • Dispensed as cartridge with 2 chambers (pastes), or two putty- system – Base: low-molecular-weight silicon with vinyl groups (paste system), or low-molecularweight silicon with silane hydrogens (putty) + silica filler – Catalyst: chloroplatinic acid 39 Setting rxn • Polymerization rxn of chain lengthening and cross-linking with reactive vinyl groups, producing a stable silicon rubber. • No ethyl-alcohol by product • Some addition silicons produce hydrogen as by product, manufacturers incorporated palladium powder that absorbs hydrogen • setting time: 3-7 minutes 40 Impression making techniques • Putty/wash technique – One step – Two step 41 Polyethers • Also used for crown and bridge work since they are very accurate and also more hydrophilic than other silicons 42 Dispensing & composition • Dispensing same as other rubber materials (2 tubes) • In addition it’s supplied in pouches of base and catalyst placed in mechanical mixer. • Composition: – Base: low- molecular-weight polyether with cation reactive group – Catalyst: aromatic sulfonic acid *clinical tip: mix well to avoid irritation from unmixed catalyst. 43 Properties • • • • • Stiff, difficult to remove from undercuts Short working and setting times Setting time 3-5 minutes Sensitive to moisture and temperature More hydrophilic (must not be stored in water or disinfectant) • accurate 44 Inelastic impression materials 45 Impression compound: • Impression compound: softens with heat, hardens in the mouth. • 2 main forms: – Cakes (sheets) /low fusing – Sticks /high fusing • Clinical uses: – Sheets: • Primary impression in metal trays • To make custom trays – Sticks are used for border molding 46 Composition & properties • Composition – – – – – Thermoplastic resin and waxes Fillers to reduce flow Plasticizers Organic acids or oils Pigments • Properties – – – – Softened at 60°C, remains plastic at 45°C, firm at 37°C Heated in water not by flame Should be poured ASAP to avoid distortion Flame used to heat sticks 47 Impression plaster • Impression plaster: seldom used – Composed of plaster gypsum (Ca hemihydrae) – Used for primary impression (high P:L) – Scored with a knife in the mouth then removed and reassembled in the lab (distortion?) – Wash impression – Easy to use – Inexpensive 48 ZNO eugenol • Secondary impression for complete dentures, or wash impression (mucostatic impression) • 2 tube paste system, different colors Zinc oxide (80%) and fillers, eugenol (15%) with oils, resin, fillers. In addition to chemical accelerator (zinc acetate) • Dispensed in 2 equal lengths and mixed to homogenous color forming zinc eugenolate • Initial set:3-6 minutes, final set:10 minutes • To accelerate the setting, a drop of water or zinc acetate is added. 49 Properties • Brittle, so not suitable for areas with undercut • Flows readily • Accurate • Eugenol can be irritant (burning sensation) • Once set, dimensionally stable 50 Impression wax • Clinical uses: – Preliminary impression for edentulous patients – Bite registration – Baseplate wax used to be used for provisional crown and bridge work – Melted to correct voids in gypsum casts 51 Disinfection of impressions • The disinfectant should be compatible with the impression materials. • After taking the impression, it should be rinsed with water, excess water shaken off, and disinfectant sprayed or impression immersed in disinfectant • Protective gloves should be worn • Rinse after disinfection is complete 52 Disinfecting casts • Maybe necessary if impression was not properly disinfected, or if immersion of impression adversely affects the impression • Casts should be set and stored for 24 hours before disinfection. • Solution used: Na hypochlorite, iodophors. 53 Sterilizing trays • Trays should be properly sterilized before use • Disposable trays are recommended if appropriate • Sterilization can be achieved by heated steam, dry heat, chemical vapors 54 55