Chapter 1, Heizer/Render, 5th edition

advertisement

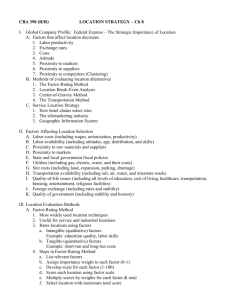

Facility Location 1 Location Decisions Long-term decisions (expand existing facilities, add new facilities, move) Difficult to reverse Affect fixed & variable costs Transportation cost As much as 25% of product price Other costs: Taxes, wages, rent etc. Objective: Maximize benefit of location to firm 2 Need for Location Decisions Marketing Strategy Cost of Doing Business Growth Depletion of Resources 3 Nature of Location Decisions Strategic Importance of location decisions Long term commitment/costs Impact on investments, revenues, and operations Supply chains Objectives of location decisions Profit potential No single location may be better than others Identify several locations from which to choose Location Options Expand existing facilities Add new facilities Move 4 Industrial Location Decisions Cost focus Revenue varies little between locations Location is a major cost factor Affects shipping & production costs (e.g., labor) Costs vary greatly between locations 5 © 1995 Corel Corp. Service Location Decisions Revenue focus Costs vary little between market areas Location is a major revenue factor Traffic volume, good transportation, customer safety and convenience most important Affects amount of customer contact Affects volume of 6 business Comparison of Service and Manufacturing Considerations Manufacturing/Distribution Service/Retail Cost Focus Revenue focus Transportation modes/costs Demographics: age,income,etc Energy availability, costs Population/drawing area Labor cost/availability/skills Competition Building/leasing costs Traffic volume/patterns 7 Customer access/parking Organizations That Need To Be Close to Markets Government agencies Police & fire departments Post Office Retail Sales and Service Fast food restaurants, supermarkets, gas stations Drug stores, shopping malls Bakeries Other Services Doctors, lawyers, accountants, barbers 8 Banks, auto repair, motels General Procedure for Making Location Decisions Decide on the criteria to use for evaluating alternatives Identify important factors Develop location alternatives - identify the general region for a location - identify community alternatives - identify site alternatives Evaluate alternatives and make a selection 9 Factors That Affect Location Decisions Regional Factors Community Considerations Multiple Plant Strategies Site-related Factors 10 Regional Factors Location of raw materials Location of markets Labor factors Climate and taxes 11 Community Considerations Quality of life Services Attitudes Taxes Environmental regulations Utilities Developer support 12 Site Related Factors Land Transportation Environmental Legal 13 Plant Strategies Single Plant Strategy Multi-Plant Strategies * Product Plant Strategy * Market Area Plant Strategy * Process Plant Strategy 14 Location Decision Sequence Region/Community Country Site © 1995 Corel Corp. . 15 Global Location Factors Government stability Government regulations Political and economic systems Economic stability and growth Exchange rates Culture Climate Export import regulations, duties and tariffs 16 Raw material availability Number and proximity of suppliers Transportation and distribution system Labor cost and education Available technology Commercial travel Technical expertise Cross-border trade regulations Group trade agreements Regional Location Factors (1 of 2) Labor (availability, education, cost and unions) Proximity of customers Number of customers Construction/leasing costs Land costs Modes and quality of transportation Transportation costs 17 Incentive packages Governmental, legal regulations, policies and barriers Environmental regulations Raw material availability Commercial travel Climate Infrastructure (cost and availability of utilities) Quality of life Regional Location Factors (2 of 2) Community government Local business regulations Government services Business climate Community services Taxes Environmental impact issues 18 Availability of sites Financial Services Community inducements Proximity of suppliers Education system Free trade zones Site Location Factors Customer base Construction/ leasing cost Site costs (land, expansion, parking, etc. Quality of life issues in the community (education, health care, sports, cultural activities etc.) Site size Transportation Traffic 19 Zoning restrictions Safety/security Competition Area business climate Income level Host community Competitive advantage Utilities including gas, electric, water and their costs Location Incentives Tax credits Relaxed government regulation Job training Infrastructure improvement Money 20 Location Evaluation Methods (Methods of Solving Location Problems) 1) Factor-rating method 2) Center of gravity method 3) Load-distance method 4) Locational break-even analysis 5) Transportation model (a specialized linear programming method)21 1. Factor Rating Method 22 Factor-Rating Method (1 of 4) Decision based on minimum distribution costs Most widely used location technique Useful for service & industrial locations Rates locations using factors Tangible (quantitative) factors Example: Short-run & long-run costs Intangible (qualitative) factors Example: Education quality, labor skills 23 Steps in Factor Rating Method (2 of 4) Identify important relevant factors Assign importance weight to each factor (0.00 – 1.00) Develop scale for each factor (such as 1 – 100) Score each location along each factor Multiply scores by weights for each factor & sum weighted factors Select location with maximum total score 24 Location Factor Rating (3 of 4) SCORES (0 TO 100) LOCATION FACTOR Labor pool and climate Proximity to suppliers Wage rates Community environment Proximity to customers Shipping modes Air service WEIGHT Site 1 Site 2 Site 3 .30 .20 .15 .15 .10 .05 .05 80 100 60 75 65 85 50 65 91 95 80 90 92 65 90 75 72 80 95 65 90 Weighted Score Site 1 = (0.30)(80) = 24 25 Location Factor Rating (4 of 4) WEIGHTED SCORES SCORES (0 TO 100) LOCATION FACTOR Labor pool and climate Proximity to suppliers Wage rates Community environment Proximity to customers Shipping modes Air service WEIGHT Site 1 Site 2 Site 3 .30 .20 .15 .15 .10 .05 .05 24.00 80 20.00 100 9.00 60 11.25 75 6.50 65 4.25 85 2.50 50 77.50 19.50 65 18.20 91 14.25 95 12.00 80 9.00 90 4.60 92 3.25 65 80.80 27.00 90 15.00 75 10.80 72 12.00 80 9.50 95 3.25 65 4.50 90 82.05 26 Best one 2. Centre of Gravity Method 27 2. Center of Gravity (Centroid) Method (1 of 10) Decision based on minimum distribution costs Finds location of single distribution center serving several destinations Used primarily for services Considers Location of existing destinations Example: Markets, retailers etc. Volume to be shipped Shipping distances (or costs) Shipping cost/unit/mile is constant 28 Center-of-Gravity Method (2 of 10) Locate facility at center of geographic area Based on weight and distance traveled Establish grid-map of area Identify coordinates and weights shipped for each location 29 Center of Gravity Method: Steps (3 of 10) This methodology involves formulas used to compute the coordinates of the two-dimensional point that meets the distance and volume criteria Place existing locations on a coordinate grid Grid has arbitrary origin & scale Maintains relative distances Calculate X & Y coordinates for ‘center of gravity’ Gives location of distribution center Minimizes transportation cost 30 Grid-Map Coordinates (4 of 10) n y 2 (x2, y2), V2 y2 y1 y3 x2 xiVi i=1 Cx = yiVi i=1 Cy = n i=1 1 (x1, y1), V1 x1 n Vi n Vi i=1 where, 3 (x3, y3), V3 Cx, Cy = coordinates of the new facility at center of gravity xi, yi = coordinates of existing facility i Vi = annual volume shipped 31 from or to the ith x3 x location Center-of-Gravity Technique (5 of 10) Example 1 y x y Vt 700 C 600 Miles 500 (135) B (105) 400 300 200 A 200 200 75 D (60) A (75) 100 0 x 100 200 300 400 500 600 32 700 Miles B 100 500 105 C 250 600 135 D 500 300 60 Center-of-Gravity Technique (6 of 10) Example 1 y n 700 xiWi Cx = C (200)(75) + (100)(105) + (250)(135) + (500)(60) = = 238 (135) 75 + 105 + 135 + 60 B i=1 600 n 500 Wi (105) Miles i=1 400 D n 300 A yiWi i = 1 200 Cy = n Wi 100 = (60) (200)(75) (75)+ (500)(105) + (600)(135) + (300)(60) = 444 75 + 105 + 135 + 60 i=1 0 100 200 300 400 500 600 700 x 33 Miles Center-of-Gravity Technique (7 of 10) Example 1 y 700 C 600 Miles 500 (135) B (105) 400 300 200 A x y Wt A 200 200 75 Center of gravity (238, 444) D (60) (75) 100 0 B 100 500 105 100 200 300 400 500 600 700 x 34 Miles C 250 600 135 D 500 300 60 Centre of Gravity Method (8 of 10) Example 2 Several automobile showrooms are located according to the following grid which represents coordinate locations for each showroom Y S ho wro o m Q (790,900) D No o f Z-Mo b ile s s o ld p e r mo nth A 1250 D 1900 Q 2300 (250,580) A (100,200) (0,0) X Question: What is the best location for a new Z-Mobile warehouse/temporary storage facility considering only distances and quantities sold35per month? Centroid Method (9 of 10) Example 2 Y To begin, you must identify the existing facilities on a twodimensional plane or grid and determine their coordinates. Q (790,900) D (250,580) A (100,200) (0,0) S ho wro o m You must also have the volume information on the business activity at the existing facilities. 36 X No o f Z-Mo b ile s s o ld p e r mo nth A 1250 D 1900 Q 2300 Centroid Method (10 of 10) Example 2 You then compute the new coordinates using the formulas: Cx = 100(1250) + 250(1900) + 790(2300) 2,417,000 = = 443.49 1250 + 1900 + 2300 5,450 Cy = 200(1250) + 580(1900) + 900(2300) 3,422,000 = = 627.89 1250 + 1900 + 2300 5,450 You then take the coordinates and place them on the map: Y S ho wro o m Q New location of facility Z about (443,627) 37 (790,900) D (250,580) Z A (100,200) (0,0) X No o f Z-Mo b ile s s o ld p e r mo nth A 1250 D 1900 Q 2300 Locational Break-even Analysis 38 Locational Break-Even Analysis Method of cost-volume analysis used for industrial locations Steps Determine fixed & variable costs for each location Plot total cost for each location (Cost on vertical axis, annual volume on horizontal axis) Select location with lowest total cost for expected production volume Must be above break-even 39 Location Break-Even Analysis Assumptions Fixed costs are constant Variable costs are linear Output can be closely estimated Only one product involved 40 Locational Break-Even Analysis Example 1(1 of 2) You’re an analyst for AC Delco. You’re considering a new manufacturing plant in Akron, Bowling Green, or Chicago. Fixed costs per year are $30k, $60k, & $110k respectively. Variable costs per case are $75, $45, & $25 respectively. The price per case is $120. What is the best location for an expected volume of 2,000 cases per year? © 1995 Corel Corp. 41 Locational Break-Even Crossover Chart (2 of 2) Annual Cost 200000 150000 100000 50000 Akron lowest cost Bowling Green lowest cost 0 0 Chicago lowest cost 500 1000 1500 2000 2500 3000 Volume 42 Example 2: Cost-Volume Analysis (1 of 3) Fixed and variable costs for Lfour o c apotential tio n F ix e d locations A B C D C ost $ 2 5 0 ,0 0 1 0 0 ,0 0 1 5 0 ,0 0 2 0 0 ,0 0 43 0 0 0 0 V a r ia b le C ost $11 30 20 35 Example 2: Solution (2 of 3) Fixed Costs A B C D $250,000 100,000 150,000 200,000 Variable Costs $11(10,000) 30(10,000) 20(10,000) 35(10,000) 44 Total Costs $360,000 400,000 350,000 550,000 Example 2: Solution (3 of3) $(000) 800 700 600 500 400 300 200 100 0 D B C A A Superior C Superior B Superior 0 2 4 6 8 10 12 Annual Output (000) 45 14 16 Transportation Method 46 Transportation Model Decision based on movement costs of raw materials or finished goods Finds amount to be shipped from several sources to several destinations Used primarily for industrial locations Seeks to minimize costs of shipping n units to m destinations Type of linear programming model Objective: Minimize total production & shipping costs (shipping n units to m destinations) Constraints Production capacity at source (factory) Demand requirements at destinations 47 Worldwide Distribution of Volkswagens and Parts 48 Global Locations Reasons for globalization Benefits Disadvantages Risks Global operations issues 49 Globalization Facilitating Factors Trade agreements Technology Benefits Markets Cost savings Legal and regulatory Financial 50 Globalization Disadvantages Transportation costs Security Unskilled labor Import restrictions Criticisms Risks Political Terrorism Legal Cultural 51 Foreign Government a. Policies on foreign ownership of production facilities Local Content Import restrictions Currency restrictions Environmental regulations Local product standards Liability laws b. Stability issues Cultural Differences Living circumstances for foreign workers / dependents Religious holidays/traditions Customer Preferences Labor Possible buy locally sentiment Resources Availability and quality of raw materials, energy, transportation infrastructure Level of training and education of workers Work ethic Possible regulations limiting number of foreign employees Language differences 52 Telemarketing and Internet Industries Require neither face-to-face contact with customers (or employees) nor movement of material Presents a whole new perspective on the location problem 53 Final Thought The ideal location for many companies in the future will be a floating factory ship that will go from port to port, from country to country – wherever cost per unit is lowest. 54