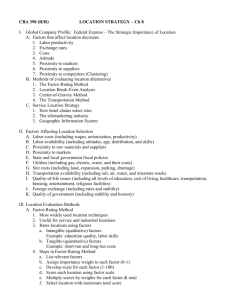

Methods of Evaluating Location Alternatives

advertisement

Methods of Evaluating Location Alternatives Charles Angotto 4 Types of Methods • The Factor-Rating Method: A location method that instills objectivity into the process of identifying hard to evaluate costs. • Locational Break-Even Analysis: The use of cost-volume analysis to make an economic comparison of location alternatives. • Center-of-Gravity Method: A mathematical technique used for finding the location of a distribution center that will minimize distribution costs. • Transportation Model: The objective of the transportation model is to determine the best pattern of shipments from several points of supply to several points of demand. The Factor-Rating Method • Popular method because a wide variety of factors can be included in the analysis. – Qualitative and Quantitative • Six Steps – – – – – – Develop a list of relevant factors called key success factors Assign a weight to each factor Develop a scale for each factor Score each location for each factor Multiply score by weights for each factor for each location Recommend the location with the highest point score Example Locational Break-Even Analysis • Used to determine which location provides the lowest cost – Can be done mathematically or graphically • Three Steps – Determine the fixed and variable cost for each location – Plot the cost for each location – Select location with the lowest total cost for expected production volume. Example Three locations: Selling price = $120 Expected volume = 2,000 units City Fixed Cost Akron Bowling Green Chicago $30,000 $60,000 $110,000 Variable Cost $75 $45 $25 Total Cost = Fixed Cost + (Variable Cost x Volume) Total Cost $180,000 $150,000 $160,000 Annual cost – $180,000 – – $160,000 – $150,000 – – $130,000 – – $110,000 – – – $80,000 – – $60,000 – – – $30,000 – – $10,000 – | – 0 | | | | | | 500 1,000 1,500 2,000 2,500 3,000 Volume Center-of-Gravity Method • Finds location of distribution center that minimizes distribution costs • This method takes into account the… – Location of markets – Volume of goods shipped to those markets – Shipping Costs for distribution center • Steps – Place existing locations on a coordinate grid – Calculate X and Y coordinates for ‘center of gravity’ Example North-South New York (130, 130) Chicago (30, 120) 120 – Pittsburgh (90, 110) + 90 – Center of gravity (66.7, 93.3) 60 – 30 – – | Arbitrary origin Atlanta (60, 40) | | | | | 30 60 90 120 150 East-West Store Location Chicago (30, 120) Pittsburgh (90, 110) New York (130, 130) Atlanta (60, 40) Number of Containers Shipped per Month 2,000 1,000 1,000 2,000 (30)(2000) + (90)(1000) + (130)(1000) + (60)(2000) x-coordinate = 2000 + 1000 + 1000 + 2000 = 66.7 (120)(2000) + (110)(1000) + (130)(1000) + (40)(2000) y-coordinate = 2000 + 1000 + 1000 + 2000 = 93.3 Transportation Model • Finds an initial feasible solution and then makes step-by-step improvements until an optimal solution is reached. – Solutions will minimize total production and shipping costs