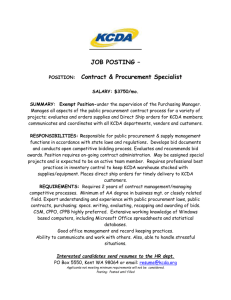

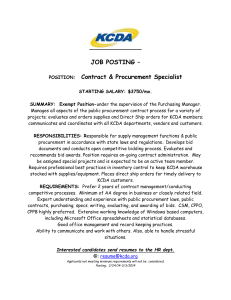

as doc

advertisement