Dietmar GLINDEMANN at National Biosolids Odors Research

advertisement

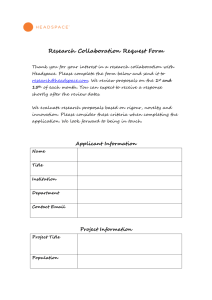

National Biosolids Odors Research Meeting @ Bucknell University, June 13, 2002 Odor Research at Virginia Tech, CEE D. Glindemann, J. Novak Dietmar Glindemann, Dglindem@vt.edu Virginia Tech, 418 Durham Hall (0246) Blacksburg, Virginia, 24061, USA ph 001-540-231-2146, fx 001-540-231-7916 e-mail dglindem@vt.edu www.glindemann.net Analytical developments - Static headspace incubation standard - Chemical odor analysis (GC, IC) - Olfactory analysis of “sticky” odor Odor Mechanisms - Do polymer flocculants cause odor? - Odor production by sludge liming - Odor problems caused by centrifuges Analytical Service Cooperation: - WSSC - Bucknell University - Private Sector Sludge Incubation Standard in closed PET polymer bottles Gas permeability of Beverage bottles made of PET(E) Gas Permeability of Plastics Permeability LDPE (cc/100 in2 /mil/day/atm) N2 180 O2 500 CO2 2700 HDPE PP PS PET PVC 42 185 580 44 190 650 50 330 1160 0.8 5 15 2 4 4 Olfactometer For “sticky” analytes (fatty acids, amines, indole, skatole) For on-line analysis of headspace in contact with sludge Calibrated by butanol-1 (40 ppm(v) = 1 European Olfactory Unit OU) Cryo-Enrichment of Odor for GC-MS analysis Net analysis time (sampling + GC): 15 min (SPME: 1 hour) Chemical classes analyzable: unlimited (FPD only sulfur, NPD only nitrogen) Detection limit similar to FPD, NPD due to enrichment and extremely narrow peaks Certified pressurized gas standards of odor compounds GC-MS – selective, sensitive, universal Ion-chromatograms of 4 organosulfurs, chloroform, trimethylamine and acetone, headspace of limed digested sludge GC-MS of Aromates and Aromatic Amines in sludge headspace GC-MS analysis of sulfides in Headspace of digested sludge Fast GC-MS of CH4, O2, CO2 in headspace of digested sludge Precision of Headspace analysis, cryofocussion and GC-MS Methane thiol (47) 35.00 30.00 25.00 20.00 15.00 10.00 5.00 0.00 Dimethylsulfide (62) Carbon disulfide (76) Disulfide, dimethyl (94) Acetone (58) Si gm a Av er ag e 5 4 3 2 Total Sulfur 1 Concentration / (mg/m3) Precision of standard injection. Sample is standard MS/DMS in Tedlar bag. 200.0 Precision of sludge headspace injection. Sample is sludge/headspace bottle Matt-7 (3d) Methane thiol (47) Dimethylsulfide (62) 150.0 Carbon disulfide (76) 100.0 Disulfide, dimethyl (94) Acetone (58) 50.0 Total Sulfur Si gm a Av er ag e 5 4 3 2 0.0 1 Concentration / (mg/m3) Number of injection, average, and standard deviation sigma Number of injection, average, and standard deviation sigma 250.0 200.0 Methane thiol, 5 times 150.0 Methane thiol, 1 times 100.0 50.0 0.0 1 and 2 17 and 18 21 and 22 29 and 30 32 and 34 37 and 38 Dimethylsulfide, 5 times 60.0 Dimethylsulfide, 1 times 41 and 42 43 and 44 41 and 42 43 and 44 40.0 20.0 0.0 1 and 2 17 and 18 21 and 22 Concentration / (mg/m3) 25 and 26 29 and 30 32 and 34 80.0 60.0 40.0 20.0 0.0 37 and 38 Disulfide, dimethyl, 5 times Disulfide, dimethyl, 1 times 1 and 2 17 and 18 Concentration / (mg/m3) 25 and 26 80.0 Concentration / (mg/m3) Concentration / (mg/m3) Concentration / (mg/m3) Influence of sampling schedule of bottles on concentration at the 5th day - 5 times: samples taken on 5 consecutive days - 1 times: sample taken only on 5th day. 21 and 22 25 and 26 29 and 30 32 and 34 37 and 38 41 and 42 43 and 44 29 and 30 32 and 34 37 and 38 41 and 42 43 and 44 8.0 Carbon disulfide, 5 times 6.0 Carbon disulfide, 1 times 4.0 2.0 0.0 1 and 2 17 and 18 21 and 22 50.0 Acetone, 5 times 40.0 Acetone, 1 times 25 and 26 30.0 20.0 10.0 0.0 1 and 2 17 and 18 21 and 22 25 and 26 29 and 30 32 and 34 37 and 38 41 and 42 43 and 44 Influence of oxygen exclusion / aeration on headspace odor Re-Aeration of anaerobicly stored sludge cake DS 906 Conc. µg S/m3 (ppb weight/volume) Methane thiol DMS CS2 DMDS Re-aerated for 1 day after 13th day of anaerobical storage Centrifuge DS 906 14181 12067 ND Horicontal Conveyor 1986 1585 215 Vertical Conveyor 643 970 ND No Air Exposure, after 14 days of anaerobical storage Centrifuge DS 906 510 835 369 Horicontal Conveyor 372 427 278 Vertical Conveyor ND 502 143 3074 691 931 ND ND ND Effect of water addition on WAS cake odor Effect of water addition on time course of Organosulfur in WAS cake. water added on day 2 of incubation, compared to dry cake Methane thiol 200.00 Dimethylsulfide Carbon disulfide 150.00 Disulfide, dimethyl Total Sulfur 100.00 50.00 Day of incubation y) 5 (d r y) 4 (d r y) 3 (d r y) (d r 2 1 (d r y) ) (3 d >w at er ) er 5 4 (2 d >w at er >w at (1 d 3 (9 0 m in >w at er ) ) 0.00 2 Concentration / (mg/m3) 250.00 Effect of Liming on Sulfur odor 5 Concentration / (mg S /m3 5 4 4 Methane thiol 3 Dimethylsulfide 3 Carbon disulfide 2 Disulfide, dimethyl 2 Total S 1 1 0 -0.1 +0.5 +2 +24 time / hours … weeks +48 +6 weeks Partitioning of TMA between liquid (sludge or water) and headspace Effect of dilution on the headspace concentration of TMA (volume of bottle 710 ml, 10 mg TMA added) 1000000 100000 10000 Total volume of liquid in bottle Concentration TMA-N in headspace, mg/m3 Partition coefficient TMA between sludge/gas 1000 100 10 1 TMA + TMA + TMA + TMA + TMA + TMA + cake + cake + cake + water water water water water water Cationic polymer flocculant bio-degradation and TMA formation (5 day incubation) Mass of TMA-N in fermentor / mg 5 day flocculant Brand 3 microaerobic fermentation by digested sludge cake 10 9 8 7 6 5 4 3 2 1 0 Flocculant-TMA added Total free TMA 4500 1500 500 150 No flocculant + sludge 1500, no sludge Polymer dosage / ppm (weight polymer /weight sludge) Mass of TMA-N in fermentor / mg 5 day flocculant Brand 3 aerobic fermentation by low biosolid WAS sludge 10.00 Flocculant-TMA added Total free TMA 8.00 6.00 4.00 2.00 0.00 4500 1500 500 150 No flocculant + sludge 1500, No sludge Polymer dosage / ppm (weight polymer /weight sludge) Mass of TMA-N in fermentor / mg 5 Polymer brands: 5 day microaerobic fermentation by high biosolid digested sludge, Polymer dosage 3333 ppm (weight) 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 Flocculant-TMA added Total free TMA Brand 1 Brand 2 Brand 3 Brand 4 Polymer Brand Name Brand 5 No flocculant + sludge Balancing of Trimethylamine (TMA) between headspace and liquid using partition coefficient liquid/vapor of 300 5 day flocculant Brand 3 anaerobic incubation using low biosolid WAS sludge No dewatering to exclude protein effects, Volume of headspace: 610 ml, Volume of liquid: 100 ml 10 Mass of TMA-N / mg 1 0.1 0.01 0.001 Flocculant-TMA added Total free TMA (liquid + headspace) Headspace free TMA 0.0001 0.00001 00 45 00 15 0 50 No e ge dg d u u l sl +s o t N 0, l an u 0 c 5 c 1 flo 0 15 Polymer dosage / ppm (weight polymer /weight sludge) Ion-chromatogram of trimethylamine (CS 16 column, 77oC, eluent 15% Acetone, 25 mM MSA) Ion chromatography analysis of trimethylamine (TMA) in dissolved form in water extracts of different sludge and sludge cake (D. Glindemann and Chris Mueller) Sludge origin Polymer flocculant added? Laboratory treatment Digested sludge No WAS sludge Raw sludge sediment, Gravity thickener, Digested sludge cake Digested sludge cake Digested sludge cake Digested sludge cake WAS sludge cake, centrifuge Blend sludge, Gravity thickener + DAF thickener WAS sludge cake, DAF thickener No No water added, centrifuged, fugate analyzed centrifuged, fugate analyzed centrifuged, fugate analyzed YES YES YES YES YES GT without polymer DAF with Polymer YES No lime 1% lime added 2% lime added 5% lime added Neutral extract (Water added, centrifuged, analyze fugate) Extract (water added, centrifuged, fugate treated with 1N HCl and analyzed after 24h) Extract (water added, centrifuged, fugate treated with 1N HCl and analyzed after 24h) Conc. TMA, mg/l n.d. n.d. 0.6 46.0 47.2 47.2 48.5 6.2 5.6 18.0 Su lfi d e (0 . 09 g N *H 2O ve r im dos um e 4 U do 0 g nd se pm er do 25 se gp 18 m gp Be m fo Ve re c r ti o n ca v l C eyo on r ve yo r pt O C 0 on / 2 .1 p 00 d tro g /p d l w et i ron sl C ud on ge t r Ad ol ) dt ( 1 00 io Ad n o g dt f 1 ca k io 0 n m e) of l 20 wa 1 t m er da l y w 6 a at da na er e y 10 s a r ob da na ic s ys ero to an bic rag ae s e ro tor ag bi c st e or ag e aS O Weighing different factors affecting sludge odor as: Polymer dosage Mechanical shear Addition of chemicals Effect of dilution with water Time of anaerobic storage (Methyl mercaptane) 1000000 100000 10000 1000 100 10 1 0 0 Odor chemistry of liming in sludge 2 CH3SH + ½ O2 (low odor threshold) CH3SSCH3 + H2O (high odor threshold) Dimerisation is catalysed by lime and amines 2 CH3SH + Ca(OH)2 2 CH3S- +Ca2+ + 2 H2O (undissociated, odorous) (ion, no odor) (CH3)3N+ (ion, no odor) odorous) (CH3)3N (undissociated, Methanethiol and Trimethylamine are highly soluble in sludge even in undissociated form TMA Partition coefficient sludge/gas 200…600 Dilution with water is reducing odor Conclusions •Incubation of sludge in closed bottles produces headspace gas in dynamic equilibrium. •PET beverage bottles are useful, economical and safe for incubation of sludge odor. •Cryotrapping GC-MS analysis of headspace is sensitive, selective and universal for bottle headspace. •Sludge Headspace odor analysis was used for mass scale incubation of sludge under various conditions to explore odor mechanisms. •All investigated TMA-based Cationic polymer flocculants can produce TMA odor by polymer breakdown. •Sludge liming is unlikely to produce trimethylamine (TMA) but it is transforming TMA into a volatile form which causes odor. •Liming reduces the odor of the most odorous sulfur compound methanethiol by the pH-effect and by dimerisation to form less odorous DMDS. •Numerous technical parameter can influence odor in addition to polymer flocculant effects.