Aggregate planning

advertisement

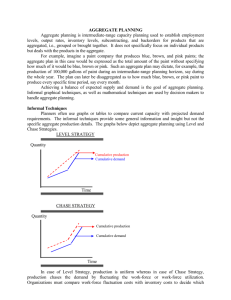

CHAPTER 3 : AGGREGATE PLANNING MOHD HAFIZUL BIN TUKIMIN MOHD SYAFIQ BIN MANSOR MOHD RUBA’I AMIR BIN SALLEH CHE MUHD FIRDAUS BIN CHE MAT OUTLINE 3.1 Introduction 3.2 Aggregate Planning Option Demand Capacity 3.3 Aggregate Unit of Production 3.4 Technique of Aggregate Planning Linear programming : Transportation Method Spreadsheet Approach Disaggregation 3.1 Introduction Aggregate planning Operational activity that does an aggregate plan for the production process in advance of 2 to 18 months. Give an idea to management as to what quantity of materials and other resources are to be procured and when. To keep the total cost of operations of the organization to the minimum over that period. 3.1.1Goal of aggregate planning • Determine the quantity and timing of production for the immediate future. • To achieve a production plan which will effectively utilize the organization’s resources to satisfy expected demand 3.1.2 Why Aggregate planning 3.1.2.1 Objectives of Aggregate Planning: – Minimize total cost over the planning horizon. – Maximize customer service – Minimize inventory investment – Minimize changes in workforce levels – Minimize changes in production rates – Maximize utilization of plant and equipment 3.2 Aggregate Planning Option Capacity - total number of units per time period that can be produced Demand - total number of units needed If capacity and demand are not balance, must decide whether: - To increase or decrease capacity to meet demand or; - Decrease demand to meet capacity Capacity Options – change capacity • Varying workforce size by hiring or lay offs • Varying production capacity through overtime • Subcontracting • Using part-time workers • Changing inventory levels Demand Options – change demand • Pricing and promotion • Back ordering • New demand creation 3.2.1 Capacity Options Varying workforce size by hiring or lay offs • Hiring additional workers as needed • Laying off workers not currently required to meet demand • Match production rate to demand • New workers may have lower productivity • Laying off workers may lower morale and productivity • Allows constant workforce • Can create temporary increase in capacity without to added expense of hiring additional worker Varying production • May be difficult to meet large increases in demand capacity through • Overtime can be costly and may drive down productivity overtime Cont……Capacity Options Subcontracting Using parttime workers • The amount of capacity or product contacted to subcontractors • Temporary measure during periods of peak demand • May be costly • Assuring quality and timely delivery may be difficult • Exposes your customers to a possible competitor • Utilizing temporary worker / casual labor • Useful for filling unskilled or low skilled positions, especially in services Cont…..Capacity Options Changing inventory levels • Increase inventory in low demand periods to meet high demand in the future • The part of the demand that is not satisfied in the intended period and is carried forward to the next periods as promised delivery Backlog 3.2.2 Demand Options Pricing and promotion • Varying pricing to increase demand in periods when demand is less than peak • Advertising, direct marketing, and other forms of promotion are used to shift demand. Back ordering • Postponing delivery on current orders demands is shifted to period when capacity is not fully utilized • Requires customers to wait for an order without loss of goodwill or the order Counter seasonal product and service mixing • Develop a product mix of counter seasonal items • May lead to products or services outside the company’s areas of expertise Option Advantages Disadvantages Avoids the costs of other alternatives. Hiring, layoff, and training costs may be significant. Matches seasonal fluctuations without hiring/ training costs. Overtime premiums; tired workers; may not meet demand. Sub-contracting Permits flexibility and smoothing of the firm’s output. Loss of quality control; reduced profits; loss of future business. Using part-time workers Is less costly and more flexible than full-time workers. High turnover/ training costs; quality suffers; scheduling difficult. Varying workforce size by hiring or layoffs Varying production rates through overtime Changing inventory Changes in human Inventory holding cost levels resources are gradual or may increase. Shortages none; no abrupt may result in lost sales. production changes. Option Advantages Disadvantages Promotion and advertising Tries to use excess capacity. Discounts draw new customers. Uncertainty in demand. Hard to match demand to supply exactly. Back ordering during highdemand periods May avoid overtime. Keeps capacity constant. Customer must be willing to wait, but goodwill is lost. Counter seasonal product and service mixing Fully utilizes resources; allows stable workforce. May require skills or equipment outside the firm’s areas of expertise. 3.4 Aggregate Units of Production The method is based on notion of aggregate units. They may be actual units of production • Weight (tons of steel) • Volume (gallons of gasoline) • Dollars (Value of sales) • Fictitious aggregate units 3.4.1 Example of fictitious aggregate units: A plant manager working for a large national appliance firm is considering implementing an aggregate planning system to determine the workforce and production levels in his plant. This particular plant produces 6 models of TVs. The characteristics of the TVs are: Model # 1 2 3 4 5 6 Number of Worker - Hours Required to produce 4.2 4.9 5.1 5.2 5.4 5.8 Selling Price $285 $345 $395 $425 $525 $725 The manager notices that the percentages of the total number of sales for these six models have been fairly constant: Model 1 2 3 4 5 6 # % of the total numbers of sales 32% 21% 17% 14% 10% 6% To find the particular aggregation scheme (1) Selling price / Number of worker-hours required = $ per Input-Hour Model # 1 2 3 4 5 6 $/hr $285/4.2 = $67.86 $345/4.9 = $70.41 $395/5.1 = $77.45 $425/5.2 = $81.73 $525/5.4 = $97.22 $725/5.8 = $125.00 Model # then 1 2 3 4 5 6 $/hr * % of Sales $67.86* 0.32 = $21.72 $70.41* 0.21 = $14.79 $77.45* 0.17 = $13.17 $81.73* 0.14 = $11.44 $97.22* 0.10 = $9.72 $125.00* 0.06 = $7.50 $78.34 what is $78.34? “Average dollars of output / worker-hour input” in this particular production plant (2) The manager decides to define an aggregate unit of production as a fictitious TV Model # 1 2 3 4 5 6 Number of worker-Hours Required 4.2*0.32 = 1.34 4.9*0.21 = 1.03 5.1*0.17 = 0.87 5.2*0.14 = 0.73 5.4*0.10 = 0.54 5.8*0.06 = 0.35 $4.86 what is 4.86 hours? “ Average worker-hours required to produce a fictitious TV” What if we like to know “ how many fictitious TV can one worker – one day (8hrs) produce ? ” [ 1 / 4.86 ] x 8 = 1.646 • Applications of this Avg. worker-hours/ TV : ~ If the manager can obtain sales forecast of overall models, then he can use this to plan workforce ~ 3.4 Technique of Aggregate Planning: 3.4.1 Spreadsheet Approach 3.4.2 Linear Programming 3.4.3 Disaggregation 3.4.1 Spreadsheet Approach Basic Relationships Workforce Number of workers in a period = Number of workers at end of previous period + Number of new workers at start of the period - Number of laid off workers at start of the period - Amount used to satisfy demand in current period Inventory Inventory at the end of a period = Inventory at end of the previous period = Output Cost (Reg+OT+Sub) + Production in current period + Hire/Lay Off Cost Cost Cost for a period + Inventory Cost + Back-order Cost Example spreadsheet The Power Star Company makes a variety of cookies . Given the following costs and monthly sales forecasts, formulate a plan that minimizes cost. They have an inventory from March of 5000 lb of cookies. Find the total cost of the production. Quarter Sales Forecast (lb) April 90,000 May 80,000 June 150,000 July 100,000 Hiring cost = $300 per worker Firing cost = $850 per worker Inventory carrying cost = $1.50 per pound per quarter Production per employee = 1,000 pounds per quarter Beginning work force = 95 workers Solution 3 Example of Spreadsheet Method • • • There are 15 workers and each can produce 20 skateboards per period. Assume a level of output rate of 300 units. Find the total cost for this plan? Technique 3: Simulation Example Level Output Period Forecast 1 2 3 4 5 6 200 200 300 400 500 200 Total 1800 Level Output Rate of 300 per period Policy: Output Cost Regular 300 300 300 300 300 300 1800 $2 Overtime $3 Subcontract $6 Output-Forecast 100 100 0 -100 -200 100 0 Beginning 0 100 200 200 100 0 Ending 100 200 200 100 0 0 Average 50 150 200 150 50 0 600 $1 0 0 0 0 100 0 100 $5 Regular $600 $600 $600 $600 $600 $600 $3,600 Inventory $50 $150 $200 $150 $50 $0 $600 Back Orders $0 $0 $0 $0 $500 $0 $500 Total Cost of Plan $650 $750 $800 $750 $1,150 $600 $4,700 Inventory Backlog Costs 3.4.2 Linear Programming 3.4.2 Linear Programming 3.4.2.1 Transportation Linear Program Description 1. Carrying costs are $2/tire/month. If goods are made in one period and held over to the next, holding costs are incurred 2. Supply must equal demand, so a dummy column called “unused capacity” is added 3. Because back ordering is not viable in this example, cells that might be used to satisfy earlier demand are not available. 4. Quantities in each column designate the levels of inventory needed to meet demand requirements 5. In general, production should be allocated to the lowest cost cell available without exceeding unused capacity in the row or demand in the column EXERCISE: solve problem 13.2 page 461 (OPERATION MANAGEMENT) A Dover, Delaware, plant has developed the accompanying supply, demand cost , and inventory data. The firm has a constant workforce and meets all its demand. Allocate production capacity to satisfy demand at a minimum cost. What is the cost of this plan? Supply capacity available (units) Demand forecast Perio d Regular time Overtime Subcontract 1 300 50 200 2 400 50 200 3 450 50 200 Other data : Initial inventory Regular- time cost per unit Over time cost per unit Subcontract cost per unit Carrying cost per unit per period Back order cost per unit per period 50 units $50 $65 $80 $1 $4 Period Demand (units) 1 450 2 550 3 750 3.4.3 Disaggregation • Aggregate plans were built to optimal staffing levels for “families” or groups of products • Disaggregation is a means to build specific “Master Production Schedules” • Typically by breaking down the aggregating weights to individual parts – or working on schedules of these families as optimal • Later leads to values similar to Economic Order Quantity(EOQ)which will explore in Chapter 4! 35