Chapter 9

advertisement

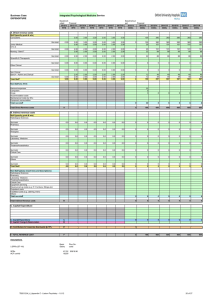

MBA 8452 Systems and Operations Management Strategic Capacity Planning & Aggregate Planning Introduction to Operations Management/ Operations Strategy Process Analysis and Design Project Management Process Analysis Planning for Production Process Control and Improvement Capacity Management Quality Management Aggregate Planning Job Design Just in Time Manufacturing Layout/ Assembly Line Balancing Services Statistical Process Control Scheduling Inventory Control Supply Chain Management Waiting Line Analysis 2 Objective: Capacity Management Overview of Capacity Management Best Operating Level What does capacity focus mean Capacity Requirements Be able to describe the best operating level Capacity Focus Be able to explain why capacity management is important Calculate capacity requirements and compare to available capacity Strategies for Meeting Demand Be able to explain the concept of Chase and Level Strategies 3 Major Operations Planning Activities Overview Long Range Process Planning Strategic Capacity Planning Aggregate Planning Medium Range Manufacturing Master Production Scheduling Services Material Requirements Planning Order Scheduling Short Range Weekly Workforce & Customer Scheduling Daily Workforce & Customer Scheduling 4 “You can’t build it if you don’t have the capacity” Strategic Capacity Planning Planning of the overall capacity level of capital-intensive resources—facilities, equipment, and overall labor force size —that supports the company’s longrange competitive strategy. 5 Capacity Planning Basic Questions What kind of capacity is needed? How much is needed? When is needed? 6 What Is Capacity? The amount of output that a system is capable of achieving over a specific period of time has a time frame can be also measured in terms of resource inputs cannot be stored for later use 7 Capacity Planning Concept Best Operating Level Design capacity for which average unit cost is at the minimum Average unit cost of output Underutilization Overutilization Best Operating Level Volume 8 Capacity Planning Concept Capacity Utilization Capacity used Utilizati on Best operating level Capacity used rate of output actually achieved Best operating level design capacity 9 Capacity Planning Concept Example - Capacity Utilization Design capacity = 50 trucks/day Actual output = 36 trucks/day Utilization = ? Solution: Capacity used 36 trucks/da y Utilizatio n = 0.72 Best operating level 50 trucks/da y 10 Economies & Diseconomies of Scale Economies of Scale and the Experience Curve working Average unit cost of output 100-unit plant 200-unit plant 300-unit plant 400-unit plant Diseconomies of Scale start working Volume 11 Capacity Planning Concept The Experience Curve Cost or price per unit Total accumulated production of units 12 Capacity Expansion Issues Maintaining system balance Inputs Stage 1 Stage 2 Stage 3 200/hr 50/hr (bottleneck) 200/hr Outputs External sources of capacity Timing and frequency of capacity expansions Volume Timing Strategy Volume Time Capacity leads demand Time Capacity lags demand 13 Capacity Expansion Issues Frequency of Capacity Expansion 14 Determining Capacity Requirements Forecast sales within each individual product line Calculate equipment and labor requirements to meet the forecasts Project equipment and labor availability over the planning horizon 15 Determining Capacity Requirements Example A manufacturer produces two lines of ketchup, FancyFine and a Generic line. Each is sold in small and family-size plastic bottles. Are we really producing two different types of ketchup from the standpoint of capacity requirements? No! The following table shows forecast demand for the next four years. Year: FancyFine Small (000s) Family (000s) Generic Small (000s) Family (000s) 1 2 3 4 50 35 60 50 80 70 100 90 100 80 110 90 120 100 140 110 16 Determining Capacity Requirements Example (cont.) Currently, three 100,000-units-per-year machines are available for small-bottle production. Two operators required per machine. Two 120,000-units-per-year machines are available for family-sized-bottle production. Three operators required per machine. Total combined demand forecasts Year: Small (000s) Family (000s) 1 150 115 2 170 140 3 200 170 4 240 200 17 Capacity Requirements Example--Calculation Year: Small (000s) Family (000s) Small Family-size Small Percent capacity used Machine requirement Labor requirement Family-size Percent capacity used Machine requirement Labor requirement 1 150 115 2 170 140 3 200 170 4 240 200 Mach. Cap. Mach. Cap. 300,000 240,000 Labor Labor 6 6 50.00% 1.50 3.00 47.92% 0.96 2.88 18 Capacity Requirements Example--Projection Year: Small (000s) Family (000s) Small Family-size Small Percent capacity used Machine requirement Labor requirement Family-size Percent capacity used Machine requirement Labor requirement 1 150 115 2 170 140 3 200 170 4 240 200 Mach. Cap. Mach. Cap. 300,000 240,000 Labor Labor 6 6 50.00% 1.50 3.00 56.67% 1.70 3.40 66.67% 2.00 4.00 80.00% 2.40 4.80 47.92% 0.96 2.88 58.33% 1.17 3.50 70.83% 1.42 4.25 83.33% 1.67 5.00 19 Planning Service Capacity Time – Location – Volatility of Demand service is perishable and must be consumed when it is produced people are not willing to travel long distances to obtain a service so they must be located near the customer – demand for services is subject to change 20 Capacity Utilization & Service Quality Best operating point is near 70% of capacity From 70% to 100% of service capacity, what might happen to service quality? Why? Context specific tradeoff 21 Aggregate Planning (Chap. 12) Matches market demand to company resources Medium-range: 6-18 months Goal: Specify the optimal combination of production rate workforce level inventory on hand 22 Inputs and Outputs to Aggregate Production Planning Capacity Constraints Demand Forecasts Size of Workforce Strategic Objectives Aggregate Production Planning Production per month (in units or $) Inventory Levels Company Policies Financial Constraints Units or dollars subcontracted, backordered, or lost 23 Strategies for Meeting Demand Level production - produce at constant rate & use inventory as needed to meet demand Chase demand - change workforce levels so that production matches demand Subcontracting - useful if supplier meets quality & time requirements 24 Level Production Demand Production Units Time 25 Chase Demand Demand Units Production Time 26