Eng. Amro Mohamed Araby - RP-Jobs

advertisement

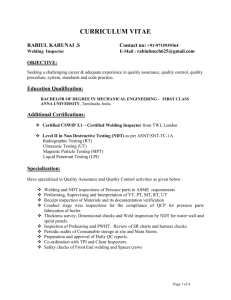

CURRICULUM VITAE : +974 66627566. Eng. Amro Mohamed Araby : +2 01121781333. E-Mail:amro.araby@gmail.com * Objective: OBJECTIVE Over 14 years of experience in the field of inspection, Corrosion, Risk Based Inspection, and QA/QC for Oil and Gas projects during construction and operations. Myresponsibilities in Qatar Petrochemical Company includethe project quality control, inspection, and RBI assessmentsforthe liveplant assets to ensure plant integrity and reliability. Familiar with Fitness for services assessments and project management concepts. * Education&Qualifications: Graduation: B.Sc. Metallurgical Engineering , Suez Canal University,1998. B.Sc. project:The effect of welding variables on properties of steel weld(Excellent evaluation). Certified Plant Inspector CSWIP-Level-1 with TWI requirement Certification No. (25205). Certified Welding Inspector CSWIP 3.1 ,with TWI requirement Certification. No.(16788). Certified Pressure Vessel Inspector,API 510 Authorized Pressure Vessel Certification. No. (40823). CertifiedPiping Inspector, API 570 Authorized Piping Inspector Certification. No. (33119). CertifiedTank Inspector,API653Aboveground Storage Tank Inspector,Certification No. (29281). CertifiedAPI-580Advanced Knowledge Risk Based Inspection Certification No. (44197). Certified ASNT-NDT inspector Level II; RT, MT, PT, UT" according to "SNT-TC-1A". *Work History: From November 2007 Till present: Employer: Qatar Petrochemicals Company(QAPCO). Job title : Inspection Engineer. Responsibilities: o Conduct root causes analysis and fitness for service assessment for degrading equipment, set the scope of corrective action, and witnesses the implementation of the quality control scope and testing. o Review, update and develop corrosion loop for piping systems and static equipment. o Conduct off-stream and on-stream inspection on the plant fixed equipment including pressure vessels, heat exchangers, drums, tanks, top and piping systems according to Company established policies and procedures. o Prepare and develop inspection procedure for piping, tanks, PRV, pipeline and static equipments. o Implements QA/QC plans adopted for capital project works being carried out in the plant, to ensure that specified maintenance practices and procedures are followed for welding, installation and fabrication as per policy and in compliance with international fabrication codes and standard. o Prepare scope of work for inspection contractors, corrective action jobs and repairs and monitor performance of contractors by carrying out surveillance inspection and supervision to follow up contractors' progress quality and review weekly and monthly progress report. o Prepare the annual plans activities in different fields as per pervious findings and company annual objectives and targets. o Produces formal written reports for pressure vessel tests specifying the condition of the equipment inspected incorporating drawings,sketches where necessary and highlighting area of concern to be used for insurance,maintenance and further planning. o Perform RBI analysis using qualitative method manually or quantitative method through asset integrity management software (GALIOM) to provide written reports and risk assessment recommendations. o Assists management`s decision making by prioritizing resources to manage risk by Identify deterioration mechanism, and predicting future deterioration rate, anticipate failure mode, Issue mitigation plan which describe the type, scope, type and timing of inspection & techniques . o Reviews welding and welder qualification procedures, witnesses these tests, interprets radiographic examination results, accepts/rejects results according to standards/company requirements and signs acceptance certificates. Page 1 of 4 CURRICULUM VITAE : +974 66627566. Eng. Amro Mohamed Araby : +2 01121781333. E-Mail:amro.araby@gmail.com o o o Attends meeting and participates in detailed shutdown planning for inspection works including reviewing equipment lists and defining specific and general inspection requirements. Supervises the external inspection services carried out in QAPCO such as radiographic inspection, or any inspection survey, to ensure that the techniques used are adequate and proper as necessary for the continued safety of the plant. Participates in the on-going development of inspection services through recommendations improvementsand assists in personnel training and counseling(technology transfer to other inspectors . From June 2005 to November 2007: Employer: Germainscher Lloyd- Oil & Gas –Doha Office, Qatar. Projects:Laffan Refinery Project, Qapco Ethylene Plant Expansion Project(EP2), and Linear Alkalin Benzen (LAB)Project. Job title: Sr.Inspection Engineer. Responsibilities: o o o o o o o o o Supervises the Quality Control activities of the project, including Quality Control inspection schedules and the collection of Quality Records. Assist the QA/QC Manager in dealing with the Client for all the Quality matters. Supervises inspections, reports and the documentation issued by inspectors and the collection & filing of the required Quality Records. Supports the construction roles in the management and control of subcontractors. Supports and participate to all the internal audits. Supervises the Welding & Non Destructive Test-NDT qualification activities. Performs all on-stream and shutdown inspection activities in the Ethylene plant for stationary equipment, piping systems, sea lines, pressure relieving devices, structures, etc Radiographs Interpretation, witness application of NDT and endorse QC reports. Review & approve WPS & PQR, witness WQT & monitor welders performance. From February 2005 to June 2005: Employer: Khalda Petroleum Company. Project :Qasr Gas Development Project. Client :Khalda Petroleum Company. Manufacture:The Petroleum Project&Technical Consultation Co. Job title : Inspection Engineer (Owner Representative). Responsibilities: o o o o o o o Review & approve WPS & PQR, method statements, and ITP’s. Ensure that the approved welding procedures are used during fabrication. Inspection of materials, consumables, and welding process. Ensure application of approved specifications, quality and safety procedures. Fully responsible for the inspection during fabrication, erection,welding, and painting for 48 skids duplex stainless steel &5 hight pressure separators. Radiographs Interpretation, witness application of NDT and endorse QC reports. Review test packages and punch lists, witness and approve pre-commissioning work. From June 2004 to January 2005: Employer:BECHTEL OVERSEAS Corporation. Project :Egyptian Liquefying Natural Gas(LNG)/Idku Port,Train 2. Page 2 of 4 CURRICULUM VITAE : +974 66627566. Eng. Amro Mohamed Araby : +2 01121781333. E-Mail:amro.araby@gmail.com Job title : Welding Inspector. Responsibilities: o o o o o Ensure that the approved welding procedures are used during fabrication. Ensure application of approved specifications, quality and safety procedures. Inspection of materials, consumables, and welding process. Responsible for inspection of stainless steel piping systems on the marine facilities. Monitor performance of subcontractors by carrying out surveillance inspection. From March 2003 to June 2004 : Employer:S.G.S Egypt Group. Member of SGS Group(Societe General De Surveillance S.A.Geneva) Project :Liquefying Natural Gas/ Dameitta Port. Client :Spanish Egyptian Gas (SEGAS). Main contactor:D.L.Cjoin venture KBR(Kellogg Brown&Root),JGC,and TR (Technicas Reunidas). Manufacture:DODSAL Pty Ltd. Job title : NDT Supervisor(RT-UT-PT-MT-PMI). Responsibilities: o o o o o o Performing and supervising all NDT activities (RT-UT-MT-PT). Monitoring any difficulties that may be delay the radiographic crews at site. Verifying daily reports for inspection activities and prepares progress reports for top management and follow up with client. Inspect and controlling all NDT equipments and ensure that they work properly and ensure that they are calibrated. Responsible for correspondences and meetings internally and with the client. Attend the safety and HSE meetings and to execute their recommendations. From March 2000 to March 2003: Employer:Materials Engineering Office (Quality control,Welding,NDT). Locations: 1. General Petrolum Company fields at Ras Gharib,Ras Sudr,and Abu Sanan. 2. Sann"a South Power Station project. 3. Edco-Dameitta Gas Pipe Line (160 Km ,32”) project. Job title : NDE Engineer / Welding Inspector. Responsibilities: o o o o o o o Performing and supervising all NDTactivities. Perform the periodical inspection and assessment for all tanks and pipelines, involving visual inspection, wallthickness measurements, NDT, leak test, etc. Perform inspection for crude oil storage tanks floor,annular plates,shell plates,and roof plates . Visual inspection of crude oil pipelines. Manage & control teamwork through assign tasks, solveing problems, control financial & administration issues. Inspection during fabrication,erection,and welding of fuel tanks according to API 650. Performing visual inspection,peaking,banding,plumbness check,and vacum box test. Page 3 of 4 CURRICULUM VITAE : +974 66627566. Eng. Amro Mohamed Araby : +2 01121781333. E-Mail:amro.araby@gmail.com From January 1999 to February 2000: Employer:Military service in the west desert. From September 1998 to January 1999 : Employer:The Islamic Co. for Feeding Industries.(FEEDICO). Location: 10th of Ramadan industrial city,factory of filters. Job title : QC Engineer. * Training courses: Project Management Professionals (PMP) course at MICA Qatar training center. Attendance of the 2nd Annual Corrosion Management Summit (6-8 May,2013,Doha,Qatar) Technical report writing course by Euromatech. Effective leadership skills by megatraining. Risk Based Inspection (APIRP 580 and 581) by TUV AKADEMIE Middle East. API 510 Pressure Vessel Inspection training by TUV AKADEMIE Middle East. Training course in"Using of ionized radiation in industrial field" from the Egyptian Atomic Authority with a governmental license for radiographic work. Occupational Safety and Health Adminstration(OSHA)certificate," Construction Safety &Health Standards" Certification. No. (600041338). Canadian Red Cross Standard First Aid course /level C CPR (College of the North Atlantic – Qatar). Microsoft Office Excel 2007 – Level 2. Introduction to Performance Management System. Job Safety Analysis. End user training of an Asset Integrity Management Software (GALIOM) by Germainscher Lloyd. *Skills: Computer: Excellent knowledge in Windows 7 Professional ,MS Office (Word, Excel, PowerPoint) ,and the Asset Mangement software (GALIOM). Experience with failure investigation techniques, root cause analysis, and familiar with ISO 9001:2008. Language (s): Arabic "Native", English Very Good "Reading, Writing, Speaking". Personality:Creative,Self Motivated, Hard worker, Team Player. Great experience working with all nationalities. * Personnel Data: Family Name:ARABYGiven Name (s): AMRO MOHAMED Date of Birth: December, 03, 1972. Nationality: EgyptianPassportNo. A00809058. Marital Status: Married “have one girl and three boys”. Military Service Status:Finished. Drive licenses:Egyptainlicense No.1810366&Qatar license No. 27281803079. Home Address: 1504, Paradise, RoyalPlaza, Montaza, Alexandria, Egypt. Page 4 of 4