CLEAN AND MAINTAIN KITCHEN EQUIPMENT AND UTENSILS

advertisement

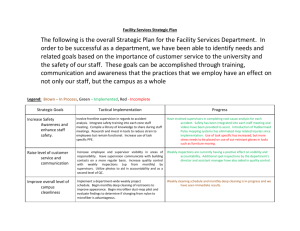

CLEAN AND MAINTAIN KITCHEN EQUIPMENT AND UTENSILS D1.HRS.CL1.03 Slide 1 Clean and maintain kitchen equipment and utensils Elements 1. Clean kitchen premises 2. Clean and maintain equipment and utensils 3. Perform basic maintenance on kitchen equipment utensils and premises 4. Handle waste and laundry requirements Slide 2 Clean and maintain kitchens Assessment for this Unit may include: Oral questions Written questions Work projects Workplace observation of practical skills Practical exercises Formal report from employer/supervisor Slide 3 Element 1: Clean kitchen premises Slide 4 Clean Kitchen Premises 1.1 Identify the areas that may require cleaning in a kitchen premises environment and the frequency of cleaning for each identified area 1.2 Select appropriate cleaning utensils and chemicals 1.3 Implement cleaning procedures in accordance with enterprise and legislated requirements 1.4 Identify and address cleaning and sanitizing needs that arise in addition to scheduled cleaning requirements 1.5 Store cleaning items and chemicals, and clean where applicable, after cleaning has been completed 1.6 Follow emergency first aid procedures in the event of a cleaning-related incident or accident Slide 5 Purpose of Food Safety Plan (FSP) FSP Cleaning Schedule The cleaning schedule will determine: When EVERYTHING is to be cleaned How it is to be clean Who is to clean How often everything will be cleaned What chemicals and equipment are to be used when cleaning Advice on OH&S equipment to be used when using cleaning chemicals. Slide 6 Identify areas to be cleaned Areas to be cleaned Floor of the kitchen Workbenches fixed and/or mobile Storerooms, shelving, floor, walls and ceilings Sinks and food disposal units Drains, in floors, especially wet areas Exhaust fans and filters Slide 7 Identify areas to be cleaned Areas to be cleaned Air conditioning outlets Light covers Staff change rooms Garbage storage areas Stock receiving areas Grease traps Walls. Slide 8 Select cleaning equipment Types of equipment Mops Brooms and brushes Cloths and sponges Buckets Protective gloves Protective face masks Warning signs Slide 9 Select cleaning equipment Types of equipment Garbage receptacles Vacuum cleaners Scrubbing machines Slide 10 Select cleaning equipment Personal Protective Equipment Hand gloves Eye goggles Aprons Footwear Airways Protection. Slide 11 Select cleaning equipment Chemicals Chemicals used for cleaning in food areas General detergent Dishwasher detergent Floor cleaner Drain cleaner Bleach Oven cleaner Grill cleaner Sanitisers. Slide 12 Process of cleaning Principles of cleaning Remove all visible waste from the area to be cleaned. Apply cleaning agent and allow it to work on the area. Remove the cleaning agent and restore area to it correct condition. Slide 13 Implement cleaning procedures Cleaning Schedule Checklists What? Who? When? With what? How often? Slide 14 Implement cleaning procedures Material safety data sheet (MSDS) A material safety data sheet (MSDS) is an important aspect of occupational safety and health. What information is contained within a MSDS? Slide 15 Implement cleaning procedures Material safety data sheet (MSDS) Physical data Toxicity or potential hazards Health effects Procedures for safe use First aid Slide 16 Implement cleaning procedures Material safety data sheet (MSDS) Reactivity Storage Disposal Protective equipment Spill-handling procedures. Slide 17 Cleaning steps Workbenches Remove any materials that are visible Wash with hot water with detergent Hot water is to soften any fats and the detergent will help remove the fats Scour with cloth or fibrous material to break up debris that is adhered to surface Rinse with hot water Allow surface to air dry Apply sanitiser and use to manufacturers’ instruction on MSDS sheet. Slide 18 Cleaning steps Utensils Cooks knives Chopping boards Stainless steel bowls Pots Pans Plates Platters. Slide 19 Cleaning steps Floors These will need to be cleaned on a daily basis. Basic cleaning will be sweeping once or twice a day. Floors in food production will have to be cleaned more regularly. Slide 20 Cleaning steps Storage areas Cool storage - refrigeration Freezer Storage Dry stores Slide 21 Cleaning steps Sinks Hand washing sinks Food washing sinks General purpose cleaning sinks Floor washing sink Slide 22 Cleaning steps Drains Covers removed Washed and sanitised. Any trapped debris removed before cleaning. If drains are cleaned on regular basis there is no need to dry them. They will air dry. Slide 23 Cleaning steps Walls of food production areas These will need to be cleaned as needed Cleaned on a weekly or fortnightly basis as stated in FSP. Higher than this can be cleaned on a 3 month cycle or as needed. Slide 24 Cleaning steps Air filters and vents Over stoves and ovens Air conditioning Air flow vents in walls. Slide 25 Cleaning steps Staff change rooms While this is not as higher priority as the food production area it is still an area that needs to be checked and cleaned regularly, daily. Staff might leave food there Possible infestation of pests of some type Smells tend to build Slide 26 Cleaning steps Garbage bins and Garbage storage areas Use plastic liners Wash bins every time they are emptied Cleaned on a daily basis Allowed to air dry Relined with clean plastic liner Lid replaced Slide 27 Cleaning instructions Work Instruction or Job Safety Analysis Sheets A Work Instruction (WI), Job Safety Analysis (JSA) or SOP (Standard Operating Procedure) may be provided by the employer to assist in cleaning and in the application of chemicals. What information is provided? Where can these sheets be accessed? Slide 28 Additional cleaning required Breakages Unexpected and not part of cleaning schedule Immediate response required Spillages Unexpected and not part of cleaning schedule Immediate response required Allowances have to be made to all schedules for the unexpected. Slide 29 Store cleaning items Condition Clean ready for later use Position Close to the kitchen Responsibility Last person to use Slide 30 Store cleaning chemicals Condition Secured in container it was delivered Position Chemical storage area Sealed Responsibility Last person to use Slide 31 Store cleaning chemicals General storage conditions Keep in a storeroom away from other products A register should be maintained to record items The store room must be well lit and ventilated The room should only be used for storing chemicals Heavy containers must be stored on lower shelves Keep containers well sealed and labelled Slide 32 Store cleaning chemicals General storage conditions Have MSDS and first aid directions posted in the area First aid resources to support possible treatment requirements Keep away from a naked flame or excessive heat Product usage charts should be close to the chemicals for easy and clear reference purposes Instructions for safe chemical handling must be poste Necessary PPE should be present Slide 33 Store cleaning chemicals General storage conditions Never store chemicals or cleaning agents in food containers Never store chemicals with food Do not allow customers to come into contact with chemicals Never mix chemicals together Ensure measuring devices for chemicals are not used for any other purpose. Slide 34 Emergency first aid procedures Emergency first aid procedures may include: Notifying internal first aid officers of emergencies Contacting external emergency services for assistance Administering basic first aid for minor cuts, bruises, abrasions, burns and scalds. Slide 35 Emergency first aid procedures Additional requirements: Material Safety Data Sheets Internal First Aid officers Correct use and storage of chemicals Applying appropriate first aid measures in emergency situations International language signage Photo signage and instructions Slide 36 Emergency first aid kit Condition Fully stocked Position Easy access to staff Responsibility Enterprise Slide 37 Work projects: Clean kitchen Premises Summary: Identify Areas to be cleaned Cleaning utensils to be used Chemicals to be used Cleaning procedures Additional cleaning Store cleaning equipment Emergency First Aid Slide 38 Element 2: Clean and maintain kitchen equipment and utensils Slide 39 Clean and maintain kitchen equipment and utensils 2.1 Identify the equipment and utensils that may require cleaning in a kitchen premises environment and the frequency of cleaning for each identified item 2.2 Select appropriate cleaning utensils and chemicals 2.3 Implement cleaning procedures in accordance with enterprise and legislated requirements 2.4 Store and protect equipment and utensils that have been cleaned ready for future use 2.5 Store cleaning items and chemicals, and clean where applicable, after cleaning has been completed 2.6 Follow emergency first aid procedures in the event of a cleaning-related incident or accident Slide 40 Identify equipment cleaning needs General cleaning requirements Follow manufacturer’s instructions in relation to using chemicals on the equipment Follow manufacturer’s instructions when cleaning their equipment Pay attention to the job Don’t cause any damage to anything being cleaned Slide 41 Cleaning and sanitation What is the difference between cleaning and sanitising? What do the customers expect? What does your Food Safety Plan state? Slide 42 Cleaning and sanitation Cleaning Removal of visible dirt and debris (including rust) either from crockery, cutlery, glasses, equipment or Removal of odour Sanitation Killing of microbes using either hot water or chemicals Slide 43 Cleaning utensils Free from foreign matter Free from visible matter Bacteria reduced to safe level Dry to touch Slide 44 Cleaning procedures What is to be cleaned? When can it be cleaned? What equipment is needed for cleaning? Alternatives? Everything cannot be cleaned at same time Map out cleaning plan in Food Safety Plan Slide 45 Select appropriate utensils for cleaning Kitchen items to be cleaned Crockery Glassware Cutlery Utensils Pots, pans and other dishes Containers Chopping boards Knives Slide 46 Select cleaning chemicals Types of cleaning chemicals General detergent Dishwasher detergent Floor cleaner Drain cleaner Bleach Oven and Grill cleaner Sanitisers Slide 47 Cleaning procedures Cleaning procedures for a kitchen Once items to be cleaned are identified and the correct cleaning items and chemicals are selected, it is now time to start cleaning. What policies and procedures must apply? What standards of cleaning exist? Slide 48 Cleaning procedures General standards of cleanliness A food business must ensure the following equipment is in a clean and sanitary condition: Eating and drinking utensils The food contact surfaces of equipment General area Slide 49 Cleaning procedures A ‘clean and sanitary condition’ means a surface or utensil: Is clean Has had applied to it heat or chemicals The number of micro-organisms on the surface or utensil has been reduced to a level that: Does not compromise the safety of the food Does not permit the transmission of infectious disease. Slide 50 Cleaning procedures No accumulation of: Garbage, except in garbage containers Recycled matter, except in containers Food waste Dirt Grease; or Other visible matter. Slide 51 Cleaning procedures Food premises must be kept clean to: Minimise the likelihood of food becoming contaminated Discourage pests Slide 52 Food Safety Plans Food Safety Plans Why is it important to have a Food Safety Plan? What information should be included? How can they be accessed by staff? Slide 53 Cleaning and hazard checklists Using cleaning and hazard checklists A list of hazards that are likely to occur when performing cleaning tasks An aid for understanding safety/hazard assessments Is not a comprehensive list for all cleaning tasks. Slide 54 Storing cleaned equipment Equipment storage: Must be clean Must be dry Store so it cannot be contaminated Protect from contamination Ready for use next time Slide 55 Storing cleaned equipment Importance of keeping items dry Dry before storing All equipment must be dry before being placed in storage Moisture encourages bacteria to thrive Bowls turn upside down Dust does not settle on food surface Slide 56 Store cleaning equipment after use Safe storage Specific area for storing Will be there when required Clean before storing Will be clean ready for use Slide 57 Store cleaning chemicals Store chemicals separately Store safely Secure area Well ventilated Slide 58 Follow first aid procedures Cleaning related injuries Slips on wet floors Burns from hot equipment Skin burns by contact to skin by cleaning chemical Chemical burns internally caused by breathing in fumes from cleaners and solvents Falling equipment that has not been stored properly. Slide 59 Follow first aid procedures Procedure to follow when aiding a person who has been injured Look before you do anything, do not put yourself in harm’s way Make sure what has caused the injury is isolated or the injured person can be moved away from cause of injury. Administer basic first aid Slide 60 Follow first aid procedures Administering basic first aid for minor cuts, bruises, abrasions, burns and scalds What are basic first aid procedures for: Minor cuts Major Cuts Burns and Scalds Bruises from falls Abrasions Chemical burns on skin Slide 61 Clean and maintain kitchen equipment and utensils Summary: Identify what has to be cleaned and when Select cleaning utensils and chemicals Implement cleaning procedures Store cleaned equipment Store cleaning items Emergency first aid Slide 62 Element 3: Perform basic maintenance on kitchen equipment, utensils and premises Slide 63 Perform basic maintenance on kitchen equipment, utensils and premises Performance Criteria 3.1 Perform basic premises maintenance activities as necessary 3.2 Perform basic maintenance activities on equipment and utensils as needed 3.3 Report maintenance requirements that cannot be satisfactorily addressed Slide 64 Basic premise maintenance Basic premises maintenance Tightening loose fittings Replacing minor items that are damaged or pose risk Replacing light globes, tubes, starters and covers, as required Replacing torn or damaged fly screens Taking short-term remedial action to prevent a dangerous or sub-standard situation, from worsening. Contacting the relevant person/department to effect professional repairs Slide 65 Basic premise maintenance Routine / preventative maintenance Why is this important? What activities can be undertaken? Who should do this? When should it be done? Slide 66 Basic premise maintenance Routine / preventative maintenance Wiping down and cleaning surfaces Washing and rinsing of items Sanitising items Drying items out Dismantling and reassembling items correctly Emptying items Changing filters Slide 67 Identifying maintenance requirements Identifying items needing maintenance How can you identify if items need maintenance? What should you do with these items? How do you report the need for maintenance? Slide 68 Handling maintenance requirements Handling items needing maintenance Equipment should be removed from service as soon as a fault has been identified Equipment should be labelled clearly and obviously ‘Out of Service’ Equipment should be stored in the appropriate ‘Out of Service’ area Appropriate ‘Report Fault’ paperwork should be completed Slide 69 Perform basic maintenance on kitchen equipment, utensils and premises Summary: Perform basic premises maintenance Equipment basic maintenance activities Report maintenance requirements Slide 70 Element 4: Handle waste and laundry requirements Slide 71 Handle waste and laundry requirements Performance criteria: 4.1 Dispose of internal waste in accordance with enterprise and legislated requirements 4.2 Maintain waste disposal area in a clean and sanitary condition 4.3 Gather dirty linen from kitchen and associated departments and process dirty linen Slide 72 Dispose of internal waste Define internal waste: Food Chemical Fats and oils Liquid waste Paper waste Plastic waste Slide 73 Dispose of internal waste Define internal waste: Organic waste Waste that will break down in landfill Food Paper waste Slide 74 Dispose of internal waste Define internal waste: Non Organic waste Will not decompose on land fill: Chemical Fats and oils Plastic waste Aluminum cans Glass bottles Slide 75 Dispose of internal waste Refuse, reduce, recycle ‘Reuse’ encourages the use of a product more than once before it is discarded. ‘Reduce’ ask people to generate less waste by thinking more about what they buy and what they use. ‘Recycle’ suggests that products can be re-made into something else. Slide 76 Dispose of internal waste Recycle Organic waste Non Organic waste Separate into specific containers: Chemical Fats and oils Plastic waste Aluminum cans Glass bottles Slide 77 Dispose of internal waste Recycle Organic waste Anything that will decompose: Food products Paper products wrapping Dirt off the floor Slide 78 Maintain waste disposal area Waste disposal areas: Garbage areas Refrigerated garbage areas Garbage chutes Bins, hoppers, garbage chutes Compacter systems. All must be cleaned on regular, DAILY, basis. Slide 79 Maintain waste disposal area Management of waste disposal areas Adequately contain the volume and type of garbage and recyclable matter on the food premises Enclose the garbage or recyclable matter to keep pests and animals away from it Areas are designed and constructed so that they may be easily and effectively cleaned . Slide 80 Disposing of food Handling food for disposal A food business must ensure that food for disposal is held and kept separate until it is: Destroyed Used for purposes other than human consumption Returned to its supplier Further processed in a way that ensures its safety and suitability; or Ascertained to be safe and suitable. Slide 81 Disposing of chemicals Disposing of cleaning chemicals Chemicals have become dated Containers have lost their labels and you don’t know what’s inside You change suppliers and elect to start this new relationship You decide to discontinue using a certain product There has been a spill and you need to get rid of the product that has been cleaned up. Slide 82 Disposing of chemicals Disposing of cleaning chemicals This disposal of chemicals must be done safely and according to environmental conditions This means: Cleaning chemicals must not be poured down the sink/gully trap Cleaning chemicals must not be thrown out with normal rubbish. Slide 83 Manage dirty linen and process May include: Kitchen Uniforms Kitchen cleaning cloths Table linen. Slide 84 Manage dirty linen and process Processes may include: Sorting Notifying laundry Transporting Returning clean linen Checking returned linen. Slide 85 Handle waste and linen Summary: Internal waste Separate Recycle Waste disposal area Tidy Clean Dirty linen Manage. Slide 86