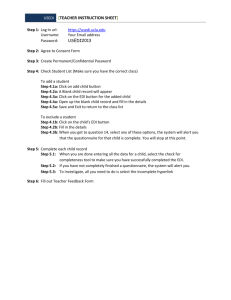

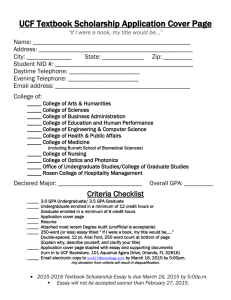

ECT 250: Survey of e-commerce technology

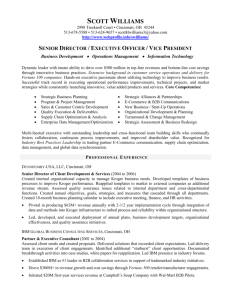

advertisement

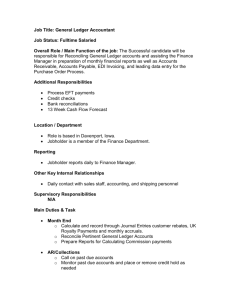

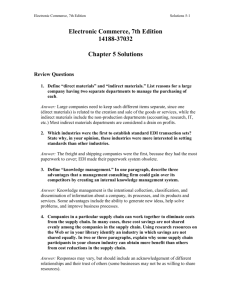

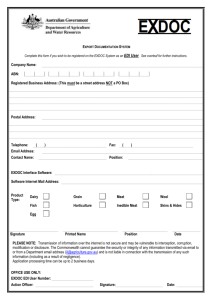

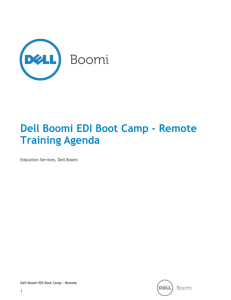

ECT 250: Survey of e-commerce technology Purchasing, logistics, and support activities Perspective • In previous lectures we talked about ways that goods and services are marketed, promoted, and sold. • In terms of the value chain, this involves: – Identify customers – Market and sell – Deliver • We now consider how technology can improve: – Purchasing – Logistics – Support 2 Figure 1-10 3 Purchasing Purchasing activities include: • Identifying vendors • Evaluating vendors • Selecting specific products • Placing orders • Resolving issues that arise after receipt of goods or services: – Late deliveries – Incorrect items or quantities shipped – Defective items 4 Procurement • The term procurement refers to all purchasing activities, as well as the monitoring of all elements of purchase transactions. • Procurement also includes the management and development of relationships with suppliers. • In many case procurement staff must have detailed knowledge about products. • Specialized Web sites can aid in disseminating necessary information. Example: Neoforma 5 MRO supplies • Maintenance, repair, and operating (MRO) supplies are commodity items that companies buy on a recurring basis. • Price is usually the main selection criterion. • By using a Web site to process orders, vendors in this market can save the cost of printing and shipping catalogs and the cost of handling telephone orders. • Examples: W.W. Grainger, McMaster-Carr, Office Depot, Digi-Key, Global Computer Supplies 6 Logistics • Objective: Provide the right goods in the right quantity in the right place at the right time. • Major transportation companies want to be seen as information management firms as well as freight carriers. Example: Freight tracking Web pages made available by Schneider Logistics, FedEx, UPS. • Logistics activities include receiving, warehousing, inventory control, vehicle scheduling and control, and finished goods distribution. 7 Support activities Support activities include: • Finance and administration • Human resources • Technology development 8 Finance and administration • Making payments • Processing payments received • Planning capital expenditures • Budgeting and planning • Operation of the computing infrastructure 9 Human resources • Hiring • Training (not always) • Evaluating employees • Benefits administration • Complying with government record-keeping regulations 10 Developing technology Activities included here depends on the nature of the business or organization. May include: • Networking of researchers into virtual collaboration • Posting of research results • Publishing research papers online • Providing connections to outside sources of research and development services 11 Training • In some companies training is handled by human resources. • In other organizations it may decentralized and be done by individual departments. • Where it occurs can depend on the type of training. • Example: At DePaul orientation for benefits and for incoming faculty is handled by a centralized group. CTI does its own training for advising. 12 Examples Examples of firms providing support activities services: • OnLine Benefits: Benefit management • TheTrip.com: Employee travel policies • CyLex Systems: Document storage • PayMaxx: Payroll processing • Driveway Business Solutions: Electronic file storage 13 Forms of economic organization Three different forms of economic organization: • Markets: Buyers and sellers come together to conduct transactions • Hierarchies: Large organizations that conduct many different business activities entirely within the structure of the firm • Networks: Firms coordinate their strategies, resources, and skills sets by forming long-term, stable relationships based on a shared purpose. 14 Effect of technology • One trend in in purchasing, logistics, and support activities is a move away from hierarchical structures toward network structures. • Highly specialized firms can now exist and trade services very effectively on the Web. • The emerging networks of firms are more flexible and can respond to changes in the economic environment more quickly than hierarchical companies. 15 Electronic data interchange • Electronic data interchange (EDI) is a computerto-computer transfer of business information between firms that use a standard format for representing the information. • The two businesses trading information are called trading partners. • Firms that exchange data in specific standard formats are said to be EDI-compatible. • The types of information include invoices, purchase orders, requests for quotations, bills of lading, and receiving reports. 16 Early efforts • By the 1960s companies began exchanging punch cards or magnetic tape with transaction data. • Data communications improvements resulted in phone lines being used to exchange information. • In 1968 a number of freight and shipping companies formed the Transportation Data Coordinating Committee (TDCC). The TDCC created a format including all elements found on bills of lading, freight invoices, shipping manifests, and other paper forms. • Standardization across industries remained difficult. 17 Broader standards • In 1979, the American National Standards Institute (ANSI) chartered a new committee, called the Accredited Standards Committee X12 (ASC X12) to develop uniform EDI standards. • The ASC X12 standard benefited from member participation across a wide variety of industries. • The current standard includes specifications for several hundred transaction sets, which are the names of the formats for specific business data interchanges. 18 International standards • Although the ASC X12 standards were quickly adopted by major firms in the U.S., businesses in other countries continued to use their own standards. • In 1987, the United Nations published its first standards under the title EDI for Administration, Commerce, and Transport (UN/EDIFACT). • The ASC X12 organization has voted to move its U.S. standards toward the UN/EDIFACT standards, although no date for the final migration has been set. 19 Paper versus EDI • Example: A company that needs to replace one of its metal cutting machines. • Figure 9-5 on page 294 shows the paper version. • Figure 9-6 on page 298 shows the EDI version. • The same messages are exchanged between the departments, but EDI reduces paper flow and streamlines the interchange of information both within and outside a company. 20 Implementation Trading partners can implement the EDI network and EDI translation processes in several ways. Each of these uses one of two basic approaches: 1. Direct connection 2. Indirect connection 21 Direct connection • Each business in the network operates its own on-site EDI translator computer. • The EDI translator computers are then connected directly to each other using modems and dial-up telephone lines or dedicated leased lines. • Trading partners using different communication protocols can make direct connection options difficult to implement. 22 Indirect connection • A value-added network (VAN) is a company that provides communications equipment, software, and skills needed to receive, store, and forward electronic messages that contain EDI transaction sets. • In an indirect connection, the trading partners use the services of a VAN for communication. • The VAN often supplies EDI translator software as part of their package of services. 23 Advantages The benefits of using a VAN include: • Support for only one communications protocol • The audit log maintained by the VAN can be used to resolve disputes. • The VAN can provide translation if the partners use different transaction sets. Examples of VAN services include General Electric Information Services, IBM Global Services, GPAS, and Sterling Software. 24 Disadvantages The disadvantages of using VAN include: • Requires an enrollment fee, a monthly maintenance fee, and a transaction fee. • Using VAN is cumbersome for companies that want to do business with a number of trading partners using different VANs. – Costs are unpredictable and tend to be higher – There is not always a clear paper trail 25 EDI on the Internet • The Internet was seen as a way to replace leased lines and dial-up connections. • Potential problems include: – Concerns about security – Inability to provide audit logs – Third-party verification of message transmission and delivery 26 Open EDI • EDI on the Internet is called Open EDI. • Many new firms offer Open EDI including: – Commerce One – EB2B.com – VanTree • The Internet allows customization for data exchanges. • New tools such as XML are helping trading partners be more flexible in exchanging detailed information. 27 Financial EDI • The EDI transaction sets that provide instructions to a trading partner’s bank are called financial EDI (FEDI). • EDI-capable banks are those banks that are equipped to exchange payment and remittance data through VANs. • Value-added banks offer VAN services for nonfinancial transactions. 28 Perceived risk • Many companies are reluctant to send over the Internet FEDI transaction sets that contain transfer instructions for large amounts of money (in some cases millions of dollars) because of the perceived low level of Internet security. • Reliability of FEDI transaction sets is also an issue since a delay in delivery of $10 million can result in a large loss of interest income. 29 Hybrid solutions • Hybrid EDI solutions use the Internet for part of the transaction. • For example, EDI-HTML translation services allow EDI-enabled firms to communicate with firms that are non-EDI-enabled. – EDI-enabled firm transmits document to the service – The service translates this into HTML for the non-EDI-enabled partner – The partner’s response is translated back 30 Supply chain • The part of an industry value chain that precedes a particular strategic business unit is often called a supply chain. • A company’s supply chain for a product or service includes all the activities undertaken by every predecessor in the value chain to design, produce, promote, market, deliver, and support each component of that product or service. • Example: Car manufacturer’s supply chain would include engine manufacturers, steel fabricators, glass manufacturers, etc. 31 Supply chain management • In recent years businesses have realized that they can save money and increase product quality by negotiating more actively with suppliers. • Companies can work together with suppliers to identify new ways to serve customers more quickly and cheaply. • The process of taking an active role with suppliers to improve products and processes is called supply chain management. 32 Levels in the supply chain • Business develop long-term relationships with a small number of very capable suppliers, called the tier one suppliers. • Tier one suppliers work with a select group of their suppliers in the same way. This second level is called the tier two suppliers. • Tier two suppliers work with tier three suppliers. • The long term relationships created are called supply alliances. 33 Value creation • In exchange for stability, buyers expect price reductions and quality improvements from their suppliers. • By working together, supply chain members reduce costs and increase the value of the product or service to the consumer. • With clear communication up and down the supply chain, each participant can know what the ultimate consumer is demanding and can plot a strategy to meet the demand. 34 Technology in the supply chain • Clear communications and quick responses to those communications are a key element of successful supply chain management. • The Internet and the Web can be very effective communication enhancers. • Software can help all members of the supply chain review past performance, monitor current performance, and predict when and how much of certain products need to be produced. 35 Advantages Suppliers can: • Share information about demand fluctuations • Receive rapid notification of product design changes and adjustments • Provide specifications and drawings more efficiently • Increase speed of processing transactions • Reduce cost of handling transactions • Reduce errors in entering transaction data • Share information about defect rates and types 36 Example • Dell computer has used technology-enabled supply chain management to give customers exactly what they want. • It reduced inventories from three weeks’ sales to six days’ sales. • Dell’s top suppliers have access to a secure Web site that lets them see: – The latest sales forecasts – Planned product changes – Defect rates and warranty claims This enables the suppliers to plan better. 37