Confined Space Rescue

advertisement

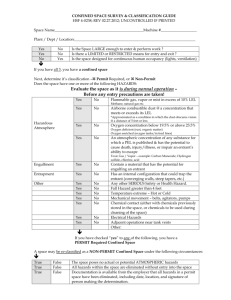

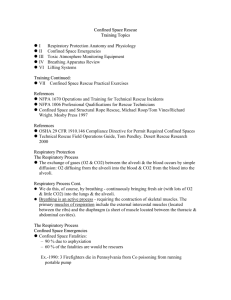

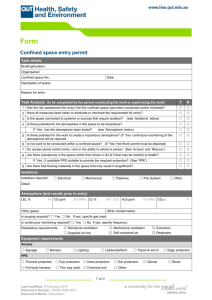

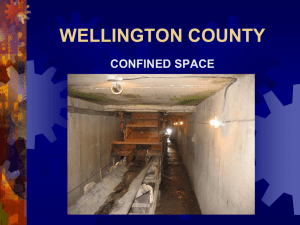

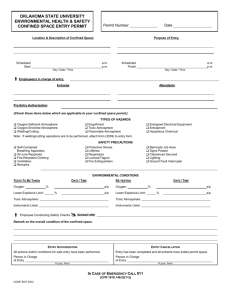

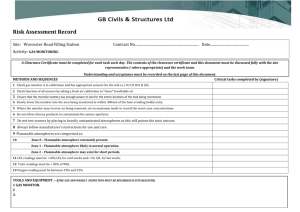

Confined Space Rescue Training Topics I II III IV VI Respiratory Protection Anatomy and Physiology Confined Space Emergencies Toxic Atmosphere Monitoring Equipment Breathing Apparatus Review Lifting Systems Training Continued: VII Confined Space Rescue Practical Exercises References NFPA 1670 Operations and Training for Technical Rescue Incidents NFPA 1006 Professional Qualifications for Rescue Technicians Confined Space and Structural Rope Rescue, Michael Roop/Tom Vines/Richard Wright. Mosby Press 1997 References OSHA 29 CFR 1910.146 Compliance Directive for Permit Required Confined Spaces Technical Rescue Field Operations Guide, Tom Pendley. Desert Rescue Research 2000 Respiratory Protection The Respiratory Process The exchange of gases (O2 & CO2) between the alveoli & the blood occurs by simple diffusion: O2 diffusing from the alveoli into the blood & CO2 from the blood into the alveoli. Respiratory Process Cont. We do this, of course, by breathing - continuously bringing fresh air (with lots of O2 & little CO2) into the lungs & the alveoli. Breathing is an active process - requiring the contraction of skeletal muscles. The primary muscles of respiration include the external intercostal muscles (located between the ribs) and the diaphragm (a sheet of muscle located between the thoracic & abdominal cavities). The Respiratory Process Confined Space Emergencies Confined Space Fatalities: – 90 % due to asphyxiation – 60 % of the fatalities are would be rescuers Ex.-1990: 3 Firefighters die in Pennsylvania from Co poisoning from running portable pump Example: PA Deaths On May 1, 1990, a 39-year-old male volunteer firefighter died inside a 33-footdeep water well in Pennsylvania while attempting to pump water out of the well. Also, two male volunteer firefighters (ages 40 and 20) died attempting rescue. http://www.cdc.gov/niosh/injury/traumacsfa ce.html#1990 (other examples) C-Space Definition OSHA 29 CFR 1910.146 – An OSHA confined space is defined as: A.-A space large enough for personnel to physically enter B.-Not designed for continuous occupancy C.-An area with limited entry and egress Examples Examples include but are not limited to: – Storage tanks, process vessels, bins, silos, boilers, ventilation/exhaust ducts, sewers, pipes, electrical vaults, steam tunnels, underground utility vaults, tunnels, pipelines, manure pits, elevator shafts, etc. etc. etc. Permit Required C-Space A confined space permit is required if the space has one or more of the following hazards: – 1. Atmospheric hazards – 2. Configuration hazards – 3. Engulfment hazard – 4. Any other recognized hazard Purpose of Confined Space Entry Permit An entry permit is a document prepared by the employer or employer representative. It is designed to be used as a checklist to document the completion of all steps necessary to prepare for safe entry and work in a confined space. Sample Permit Purpose of Confined Space Entry Permit The entry supervisor must sign the entry permit to: 1.-make sure acceptable conditions have been attained in the permit space; and 2.-authorize entry. Further, you must post the permit near the confined space entry for entrants to verify that pre-entry procedures have been completed. Non-Permit C-Space A non-permit required confined space is: – 1. Spaces that do not contain, nor has the potential to contain, any uncontrolled hazards capable of causing death or serious physical harm – 2. Space in which all the hazards in a permit space can be eliminated C-Space Entry Risk Profile A permit required confined space has less risk if it meets the following criteria: – A. The internal configuration of the space is clear and unobstructed so retrieval systems can be used for rescuers without the possibility of entanglement Entry Risk Pro-file cont. – B. The victim can be easily seen from the outside the space’s primary access opening – C. Rescuers can pass easily through access/egress opening(s) with room to spare with appropriate PPE – D. The space can accommodate two or more rescuers in addition to the victim – E. All hazards in and around the space have been ID’d , isolated and controlled C-Space Entry Risk Profile A permit required confined space has more risk if any of the following conditions or other hazardous conditions exist – A. Presence of downed rescuer – B. Victim’s location and condition are unknown – C.-Hazards are known to exist that cannot be completely isolated or controlled Entry Risk Profile cont. – D. The internal configuration of the space makes line management difficult and hinders retrieval of lines by rescuers (Interpreted from NFPA 1670) C-Space Hazards It should always be considered that the most unfavorable situation exists in every confined space and that the danger of explosion, poisoning, and asphyxiation will be present at the onset of the emergency Hazard Types Hazards specific to a confined space are dictated by: 1.-The material stored or used in the confined space – Ex. Damp activated carbon in a filtration tank will absorb oxygen, creating an oxygen deficient atmosphere Hazard Types cont: 2-The activity carried out: – Such as the fermentation of molasses that creates ethyl alcohol vapors and decrease the oxygen content of the atmosphere Hazard Types cont: 3-The external environment – As in the case of sewer systems that may be affected by rising water, heavier than air gases, or flash floods The most hazardous kind of confined space is the type that combines limited access and mechanical devices C-Space Hazard Groups Confined space hazards can be grouped into the following categories: – 1. Oxygen deficient atmosphere – 2. Flammable atmospheres – 3. Toxic atmospheres – 4. Mechanical and physical hazards Oxygen Deficient Atmosphere Normal atmosphere composed of 20.9 % oxygen, 78.1 % nitrogen and 1 % argon An atmosphere containing less than 19.5 % oxygen shall be considered oxygen deficient *O2 levels inside confined spaces may be decreased as the result of consumption or displacement* Effects of decreasing O2 Levels Level of 17 % – Increased respiratory rate, impaired coordination Between 14-16 % – Increased respiratory rate, tachycardia, rapid fatigue Between 6-10 % – Nausea, emesis, unconsciousness, 8 min.’s = 100% fatal Less than 6 % – Spasmatic breathing, death in minutes Consumption of O2 Takes place during combustion of flammable substances (welding, cutting, brazing) During bacterial action (fermentation process) During chemical reactions as in the formation of rust (iron oxide) Displacement of O2 Gas that displaces oxygen and therefore reduce the O2 levels (helium, argon, nitrogen) Nitrogen, argon, helium and carbon dioxide are used as inerting agents to displace flammable substances and retard pyrophoric reactions O2 Enriched Environment An atmosphere containing more than 23.5 % of oxygen is oxygen enriched and enhances the flammability of combustibles Flammable materials such as clothing and hair burn violently when ignited Flammable Atmospheres Arise from enriched O2 atmospheres, vaporization of flammable liquids, byproducts of work, chemical reactions or concentrations of combustible dust Work conducted in a c-space can generate flammable atmospheres (painting, coatings, solvents for cleaning) Flammable Atmosphere Terms Flash point is the lowest temperature at which a liquid can form an ignitable mixture in air near the surface of the liquid. The lower the flash point, the easier it is to ignite the material (at the flash point, the flame does not need to be sustained). Example Gasoline has a flash point of -50 degrees F (-45 C) and is more flammable than ethylene glycol (antifreeze) which has a flash point of 111 degrees C (232 F) Flammable Atmosphere Terms Fire point, the temperature at which the flame becomes self-sustained so as to continue burning the liquid The fire point is usually a few degrees above the flash point Flammable Atmosphere Terms Flammable limits apply generally to vapors and are defined as the concentration range in which a flammable substance can produce a fire or explosion when an ignition source (such as a spark or open flame) is present The concentration is generally expressed as percent fuel by volume UEL/LEL Upper flammable limit (UFL) the mixture of substance and air is too rich in fuel (deficient in oxygen) to burn. This is sometimes called the upper explosive limit (UEL) Lower flammable limit (LFL) the mixture of substance and air lacks sufficient fuel (substance) to burn. This is sometimes called the lower explosive limit (LEL) Example UEL/LEL It is usually quite easy to reach the lower flammable limit. There are numerous cases where individuals have used a solvent, sealer, or other flammable materials in a basement or closed room with inadequate ventilation...and have been injured when the vapors were ignited by a pilot light, electric spark or other ignition source Example UEL/LEL Newcastle in September of 2003 – A pipe fitter left an acetylene cylinder inside his vehicle over the weekend. Either the cylinder had a small leak or the valve was not fully closed. The flammable limits for acetylene are extremely broad, 2.5% to 100% in air – When the worker opened the door, an undetermined spark source (the door light switch, light bulb, cellular phone, static etc.) ignited the mixture with catastrophic results Acetylene Explosion Flammable Atmosphere Terms Permissible Exposure Limit (PEL) is the maximum amount or concentration of a chemical that a worker may be exposed to under OSHA Regulations 8-hour Time Weighted Averages (TWA) - are an average value of exposure over the course of an 8 hour work shift Flammable Atmosphere Terms Immediately dangerous to life or health (IDLH) atmospheres poses an immediate threat to life, would cause, irreversible adverse health effects, or would impair an individual's ability to escape from a dangerous atmosphere Flammable Atmospheres Flammable gases such as acetylene, butane, propane, hydrogen, methane, natural or manufactured gases or vapors from hydrocarbons can be trapped in c-spaces Gases heavier than air will seek lower levels as in pits, sewers, storage tanks/vessels Flammable Atmospheres In a closed top tank, lighter than air gases may rise and develop a flammable concentration if trapped ABOVE the opening Combustible dust concentrations are found during loading/offloading, conveying grain products, nitrated fertilizers and finely ground chemical products Toxic Atmospheres The source of toxic atmospheres encountered in c-spaces may arise from: – Manufacturing process – Product stored – Operation performed in the c-space Toxic Atmospheres Carbon Monoxide – Odorless, colorless gas, approximately the same density of air – Formed from incomplete combustion of organic materials – Can be formed from mircobial decomposition of organic materials in sewers/silos and fermentation tanks Measuring Toxicity Measured in terms of permissible exposure limit (PEL) PEL is the concentration of a toxin that most people could safely be exposed to for an 8 hour period Any toxin in a confined space greater than its PEL is hazardous Irritant (Corrosive) Atmospheres Irritant gases vary widely among all areas of industrial activity They can be found in plastic plants, chemical plants, petroleum industry, tanneries, refrigeration industries, paint manufacturing and mining operations Irritant (Corrosive) Atmospheres Prolonged exposure at irritant or corrosive concentrations in a c-space may produce little or no evidence of irritation Danger in this situation is that worker is usually not aware of any toxic exposure Examples: nitrogen dioxide, sulfur dioxide, ammonia Mechanical/Physical Hazards Vibrations/moving machinery – Augers, hydraulics, steam, etc. Noise – Noise problems intensified in c-space because interior causes sound to reverberate – May disrupt verbal communication with emergency personnel on the exterior of the space Toxic Atmosphere Monitoring Equipment Atmospheric monitoring should take place continuously or at frequent intervals during the rescue operation All atmospheric monitoring equipment should meet OSHA standards Equipment should be calibrated according to manufacturer’s recommendations Atmospheric Testing Procedures First set of tests should be performed by remote probe prior to entering the space All levels of the space need to be metered due to vapor densities (weight of a vapor compared to air) Principles of Air Monitoring Calibrate meters to manufacturer’s spec If O2 level is not normal, flammability readings will be affected Spaces may have stratified atmospheres, all levels of space must be metered Allow for air intake in sampling hose/probe, approx. 1 sec per foot of hose 10,000 ppm = 1 % Meters O2 Co LEL H2S Should include at a minimum audible and visual alarms Oxygen Levels According to OSHA, air containing less than 19.5 % or more than 23 % oxygen is unacceptable If oxygen level is not normal, flammability readings will be effected Atmosphere Flammability Measured in the % of the lower explosive limit (LEL) The LEL is the lowest concentration of a product that will explode or burn when it contacts a source of ignition of sufficient temperature OSHA -> C-space is hazardous if it contains more than 10 % of the LEL Lower Explosive Limit LEL A flammable gas must reach 100 % of its LEL to ignite and burn Meters are usually calibrated with a flammable gas such as methane, heptane or pentane Lower Explosive Limit LEL Methane LEL -> approximately 5 % Different gases have different LELs Meter calibrated to methane will give an inaccurate reading for a gas with a different LEL Meter reading of 10 % or less of the LEL should ensure that an atmosphere is below the LEL of most gases Common Gas Examples Methane (CH4): – Natural, marsh, swamp gas – Lighter than air, (0.6) – LEL 5 %, UEL 15 % Nitrogen (N2): – Colorless, odorless gas – Slightly lighter than air, (0.97) – May displace oxygen Common Gases Carbon monoxide (Co): – Colorless, odorless gas – Slightly lighter than air (0.97) – PEL = 50 ppm – TWA = 25 ppm – LEL 12.5 %, UEL 74. 2 % – IDLH = 1500 ppm Common Gases Hydrogen Sulfide (H2S): – Sewer gas (rotten eggs) – Produces olfactory fatigue (loss of smell) – Odor thresh hold = 0.02-0.2 ppm – Colorless flammable gas – LEL = 4.3 %, UEL = 46 % – Heavier than air (1.18) Hydrogen Sulfide Cont: – PEL = 20 ppm – TWA = 10 ppm – IDLH = 300 ppm Toxic Atmospheres Known materials: -Use meter specific to that chemical to test for these products Unknown materials: -Use meters to take readings and narrow the spectrum of chemicals -Broad spectrum analysis -Colormetric tubes Hazard Abatement Hazard Reduction Reducing or abating hazards of a confined space emergency is essential before entry is safe In addition to protective equipment, SCBA, other measures should be taken externally OSHA requires that measures be taken before permit spaces are entered Electrical Usually isolated by a combination of: – 1. Turning it off at the source and securing it with a lock device (lockout) – 2. Placing a warning of some type on the switch to deter someone from trying to turn it on (tagout) Hydraulic Includes liquids, finely divided solids that if not secured may cause exposure or engulfment Usually isolated by: – 1. Shutting off valves (blocking) – 2. Should be shut off in two locations Mechanical Hazards in the space or introduced into the space Includes energy from: – Augers, blades, conveyer belts, gears, flywheels, and anything mechanical – Need to be locked out/tagged out Ventilation Why Ventilate?? When atmospheric conditions is a c-space do not meet the limits for O2, flammability and toxic vapors, the c-space must be ventilated to bring the atmosphere into those limits. Methods of Ventilation 1. Positive Pressure (Supply) 2. Negative Pressure (Exhaust) 3. Positive negative push pull Positive Pressure (Supply) Direction of fresh air flow into space creating a positive pressure diluting any contaminants by the addition of fresh air Electrically operated fans should be used to prevent unacceptable levels of Co into space by use of gasoline blowers Air flow should be introduced into the space and the flow should be at the level at which rescuers will be working Positive Pressure Fan should be allowed to operate long enough to exchange the air content of the space several times Capacity of fan in cubic feet per minute (CFM) divided into the volume of the space in cubic feet = the time it takes to exchange air one time Positive Pressure (Supply) Positive pressure (supply) can force air into space 30 times the distance exhaust (negative) pressure can draw it Examples Super Vac's AirPac 25 duct canister allows the 25 ft. x 8 in. duct to be easily stored and rapidly deployed Negative Pressure (Exhaust) Exhausts contaminants from the space (using negative pressure) by pulling contaminated air out of a space A slight vacuum is created that can draw other contaminants into the space May draw flammable gases over motor Positive-negative/push-pull Flushes the atmosphere by supplying and exhausting large volumes of air Two portals must be present, positive air flow into space while negative pressure pulls contaminants out Most effective method for ventilation Consider where the contaminated exhaust is going and if it will pose an additional hazard Respiratory Protection Types of SCBA OSHA CFR 1910 direct that unless the cause of the emergency can be established as NOT atmosphere related, fresh air breathing apparatus must be worn Types: – Self contained breathing apparatus (SCBA) – Supplied air respirator (SAR) Self Contained Breathing Apparatus Positive pressure since 1983 Prevents contamination of the air inside the face piece if a leak occurs in the face piece’s seal Limited amount of air supply (based on wearers personal characteristics) Supplied Air Respirators During C-space rescue, conventional SCBA’s size often makes it difficult to use SCBA small enough to pass through narrow openings may limit duration of its air supply to impractical levels Supplied Air Respirators are a viable option SAR Components SAR consists of: – Open circuit face piece – Regulator – Egress cylinder attached via a low-pressure air line to remote source air supply (restricted to maximum distance allowed by manufacturers, usually no more than 300 feet from point of attachment) SAR Components OSHA requires an SAR used in an atmosphere that is immediately dangerous to life and health (IDLH) have an additional supply Must be capable of providing enough air for the wearer to escape the atmosphere in the event the primary supply is interrupted SAR Components “Escape” requirement addressed by attaching small breathing air cylinder rated at 5 minutes to the SAR unit 5 minute cylinder are intended to provide enough air for escape although they may be incapable of doing so Egress cylinder SAR Air Carts Survivair Air Cart Contains up to two independently operated 30-,45-, or 60-minute high pressure (4500 psi) cylinders Or to two independently operated 30 minute low pressure (2216 psi) cylinders An optional accessory case can hold a variety of Hip-Pac and hose combinations Survivair Air Cart Two inlets allow regulated or unregulated external air sources to be used Built-in manifold has four Foster or Schrader quick-disconnect couplings to supply air for up to four workers Used in any confined space where an SCBA would reduce or restrict worker movement Yellow Rescuer Red Rescuer AIR LINE MANAGEMENT OSHA Respiratory Standard 1910.134(e)(3)(iii) requires, when an IDLH atmosphere exists, A stand by man or men with suitable self contained breathing apparatus shall be at the nearest fresh air base for emergency rescue Safe Respiratory Work Practices 1. Rescuers should immediately withdrawal from space whenever a respiratory problem develops 2. Rescuers should wear full a full body harness and use life lines when ever practical 3. Minimum capacity of of the source air should be twice the volume of the total needs of all rescuers connected to it for the anticipated duration of the rescuer’s entry Safe Work Practices cont: 4. A minimum team of two rescuers should be utilized for all permit space rescue entries Lifting/Raising Systems Miller Tripod Miller Tripods provide a highly portable anchorage system for typical confined space entry and rescue systems Made of high-strength aluminum, the tripod withstands up to 5,000 lbs of pull yet weights only 42 lbs Legs lock independently and adjust with integral push pins allowing set up on uneven surfaces SKED EVAC Tripod Features aircraft-grade, goldanodized aluminum legs and a cast-aluminum head Three heavy-duty rigging anchors have exceptionally large holes for easy attachment and are located in the center SKED EVAC Tripod Legs adjust in 5-inch increments for a maximum height of 10 feet and a minimum length for transport of 7 feet Holes in the feet allow the tripod to be bolted into position 119 inch height / 5,280 lbs (23kN) SKED EVAC Tripod Ladder A-Frames Mechanical Advantage Systems Retrieval Systems 1910.146 (k)(3) requires that retrieval systems be used except when the retrieval equipment would increase the risk to an entrant or would not contribute to the rescue of an entrant. When a retrieval system is not used, alternate methods of retrieval must be developed. Retrieval Systems Red Rescuer Yellow Rescuer Retrieval Systems Primary Rescuer in the space, secondary rescuer being lowered in on retrieval system and a safety. MA Systems Rescuer hauler 4:1 system – 3-inch double pulley with a cam – rope can move in only one direction when the cam is engaged – allows rescuer to raise a load by pulling on the tail end of the rope, releasing it, and getting another grip MA Systems Rescuer hauler 4:1 – cam can be released manually by pulling on the attached cord – accommodates rope sizes from 3/8” (10mm) to 1/2” (12/5mm). – Minimum break strength when in use is 12,000 lb Rescuer Hauler 4:1 MA Systems 1:1 COD 2:1 MA System 3:1 MA System 6:1 MA System Patient Evacuation Devices Patient Evacuation Devices Patient packaging devices that can be used in confined spaces include but are not limited to the following: – Full spine immobilization devices – Short spine immobilization devices – Litters – Prefabricated full body harnesses – Tied full body harnesses – Wrist loops (wristlets) Prefabricated Class III Harnesses C-Space Practical Exercises C-Space Rescue Priority 1: Make the scene safe – Assess hazards – Mitigate hazards: Control or remove hazards Priority 2: Victim contact by Primary Rescuer – Establish victim location – Perform initial assessment if possible – Determine mechanism of injury – Begin psychological first aid C-Space Rescue Priority 3: Size-up -Gather information: MSDS, etc. -Risk benefit analysis (Go/no-go) -Implement ICS -Team member assignments (support personnel, ventilation, monitoring, air watch, decon, etc.) Priority 4: Preparation -Rescuer PPE -Anchoring & rigging rescue equipment -Authorized entrant review C-Space Rescue Priority 5: Access Victim -Designate Rescue Sector Officer -Utilize rescuer retrieval (high point) -Designate stand-by personnel Priority 6: Stabilize and package victim -Provide first aid to life threatening injuries -Secure packaging for rescue transport C-Space Rescue Priority 7: Evacuate -Move victim to safe location -Provide medical report to EMS -Remove rescuers from space Priority 8: Response Termination -Take up/inventory gear -Decon if necessary -Rebuild gear packs (if necessary) LINE MANAGEMENT IS CRITICAL IN ANY CSPACE ENTRY FOR THE FOLLOWING REASON: Rescue Response Non-IDLH Atmosphere – Incident Commander – Rescue Sector Officer – Entry Supervisor: Verifies tests required are complete Determines that space remains safe during work Removes unauthorized persons from space area Terminates entry if conditions are poor/degrading Rescue Response – Attendant: Knows space hazards Knows effects of exposure Remains outside space at all times Communicates with entrant(s) Monitors entry activities Calls RESCUE if needed Prevents unauthorized entry Performs no conflicting duties Rescue Response – Entrant (Primary): Knows space hazards Recognizes exposure signs/symptoms Recognizes effects of exposure Uses proper PPE Communicates with attendant Alerts attendants of hazards Rescue Response – Entrant (Stand-by): Knows space hazards Recognizes exposure signs/symptoms Recognizes effects of exposure Uses proper PPE Communicates with attendant Alerts attendants of hazards Rescuer for primary entrant Rescue Response – Support Personnel: Ventilation/metering/air watch/decon, etc. – Safety Officer: Oversees scene for safety hazards In matters of safety, has authority over the incident commander During rescue, each rescuer should consider him/herself equally responsible for safety IDLH Atmosphere – Incident Commander – Rescue Sector Officer – Entry Supervisor: Verifies tests required are complete Determines that space remains safe during work Removes unauthorized persons from space area Terminates entry if conditions are poor/degrading IDLH Atmosphere – Attendant: Knows space hazards Knows effects of exposure Remains outside space at all times Communicates with entrant(s) Monitors entry activities Calls RESCUE if needed Prevents unauthorized entry Performs no conflicting duties IDLH Atmosphere – Entrant (Primary # 1): Knows space hazards Recognizes exposure signs/symptoms Recognizes effects of exposure Uses proper PPE Communicates with attendant Alerts attendants of hazards IDLH Atmosphere – Entrant (Primary # 2): Knows space hazards Recognizes exposure signs/symptoms Recognizes effects of exposure Uses proper PPE Communicates with attendant Alerts attendants of hazards IDLH Atmosphere – Entrant (Stand-by # 1): Knows space hazards Recognizes exposure signs/symptoms Recognizes effects of exposure Uses proper PPE Communicates with attendant Alerts attendants of hazards Rescuer for primary entrant IDLH Atmosphere – Entrant (Stand-by # 2): Knows space hazards Recognizes exposure signs/symptoms Recognizes effects of exposure Uses proper PPE Communicates with attendant Alerts attendants of hazards Rescuer for primary entrant IDLH Atmosphere – Support Personnel: Ventilation/metering/air watch/decon, etc. – Safety Officer: Oversees scene for safety hazards In matters of safety, has authority over the incident commander During rescue, each rescuer should consider him/herself equally responsible for safety Wrap Up Questions Practical Exercises: – Knot Review – SCBA Review/diminished profile – Harnesses/SKED lashing – A-Frames/Gin Pole construction – Confined space exercises