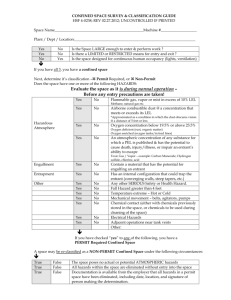

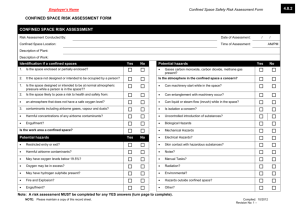

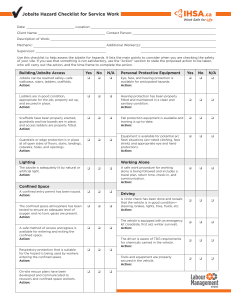

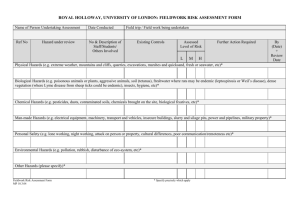

Confined Space

advertisement

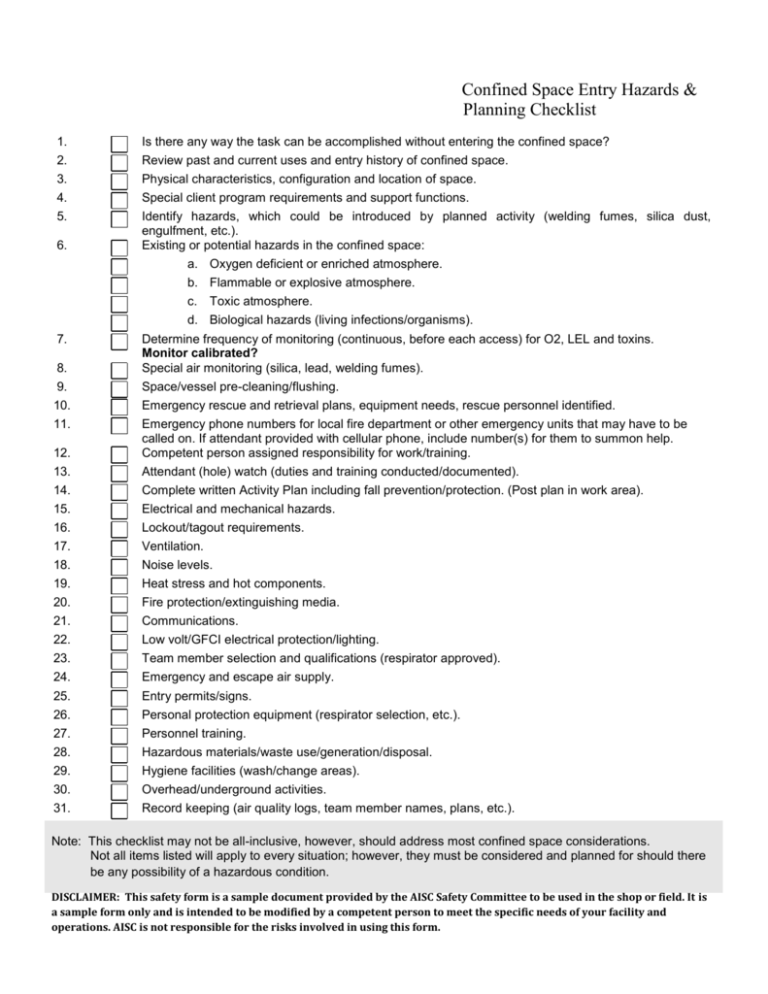

Confined Space Entry Hazards & Planning Checklist 1. 2. 3. 4. Is there any way the task can be accomplished without entering the confined space? Review past and current uses and entry history of confined space. Physical characteristics, configuration and location of space. Special client program requirements and support functions. 5. Identify hazards, which could be introduced by planned activity (welding fumes, silica dust, engulfment, etc.). Existing or potential hazards in the confined space: a. Oxygen deficient or enriched atmosphere. b. Flammable or explosive atmosphere. c. Toxic atmosphere. d. Biological hazards (living infections/organisms). 6. 7. 12. 13. 14. Determine frequency of monitoring (continuous, before each access) for O2, LEL and toxins. Monitor calibrated? Special air monitoring (silica, lead, welding fumes). Space/vessel pre-cleaning/flushing. Emergency rescue and retrieval plans, equipment needs, rescue personnel identified. Emergency phone numbers for local fire department or other emergency units that may have to be called on. If attendant provided with cellular phone, include number(s) for them to summon help. Competent person assigned responsibility for work/training. Attendant (hole) watch (duties and training conducted/documented). Complete written Activity Plan including fall prevention/protection. (Post plan in work area). 15. 16. 17. Electrical and mechanical hazards. Lockout/tagout requirements. Ventilation. 18. 19. 20. 21. 22. Noise levels. Heat stress and hot components. Fire protection/extinguishing media. Communications. Low volt/GFCI electrical protection/lighting. 23. 24. Team member selection and qualifications (respirator approved). Emergency and escape air supply. 25. 26. 27. 28. 29. Entry permits/signs. Personal protection equipment (respirator selection, etc.). Personnel training. Hazardous materials/waste use/generation/disposal. Hygiene facilities (wash/change areas). 30. 31. Overhead/underground activities. Record keeping (air quality logs, team member names, plans, etc.). 8. 9. 10. 11. Note: This checklist may not be all-inclusive, however, should address most confined space considerations. Not all items listed will apply to every situation; however, they must be considered and planned for should there be any possibility of a hazardous condition. DISCLAIMER: This safety form is a sample document provided by the AISC Safety Committee to be used in the shop or field. It is a sample form only and is intended to be modified by a competent person to meet the specific needs of your facility and operations. AISC is not responsible for the risks involved in using this form. DISCLAIMER: This safety form is a sample document provided by the AISC Safety Committee to be used in the shop or field. It is a sample form only and is intended to be modified by a competent person to meet the specific needs of your facility and operations. AISC is not responsible for the risks involved in using this form.