Big “Q”uality Equals Better Business The ISO 9001 Group

advertisement

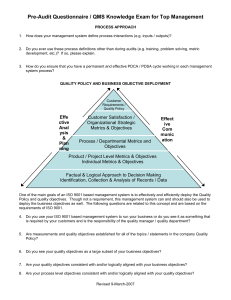

Big “Q”uality Equals Better Business The ISO 9001 Group 2002 Timberloch Place, Suite 200, The Woodlands, Texas 77380. www.iso9001group.com. Phone: 281-402-6800. Email: info@iso9001group.com So God Made The Quality Manager Published on 3/19/2013 by Mike Micklewright and Quality Digest © The ISO 9001 Group. 2011 (0) Page 2 Biography Oscar Combs, President & Senior Consultant of The ISO 9001 Group, a management system consulting firm based in Houston, Texas, which helps companies manage their risks and improve operations through providing customized consulting, auditing and training services. Oscar has successfully led and managed Quality and HSE Departments for major corporations, such as Nabors Industries and Fugro before starting The ISO 9001 Group. Oscar has over 19 years of experience providing consulting, auditing and training to organizations such as: Transocean, Hewlett-Packard, The Department of Veteran Affairs, Cameron, Halliburton and numerous other medium and small size organizations throughout the United States and abroad. Oscar has acquired invaluable national and international business experience, which he utilizes on a daily basis to assist The ISO 9001 Group client organizations in overcoming their management system challenges. Oscar has developed and successfully implemented ISO and API management systems in over 50 sites throughout North America, South America, The Middle East, and Africa. Oscar has achieved ISO 9001 Certification of 16 sites in just an astounding 12 months with zero major findings by the certification body, has a 100% success rate of achieving certification for clients and has logged over 100 audit hours. Oscar is a Senior Member of the American Society for Quality and served as the Programs Committee Chair for ASQ’s Houston Chapter 1405. Oscar also conducts keynote presentations for several organizations such as, The American Society for UBM Canon, Occupational Health & Safety.com and Human Resources.com. Oscar’s articles have been published by publications such as, Quality Progress (QP) and Quality Digest. Oscar earned his MBA from the University of Houston. He earned his Bachelor’s of Science in Business Management from the University of Phoenix. He has undergone specialized training in the areas of: Quality Management, ISO 9001 and ISO 14001 Lead Auditing, Root Cause Analysis, Project Management, OSHA Compliance, Operational Safety Management and Behavioral Based Safety. He is certified by RAB-QSA as a Principal Management Consultant. He maintains various industry memberships with organization such as, Society of Manufacturing Engineers, The Association for Operations Management (APICS). Oscar also sits on various industry boards and committees. © The ISO 9001 Group. 2011 (0). Page 3 Quality Progress Featured Article – September 2013 © The ISO 9001 Group. 2011 (0). Page 4 From Quality Manager to Risk Manager Quality Managers are Business and Risk Managers Quality Managers need to have a seat at the table where decisions are being made that will have an impact on operations The experience, skills, education and training of a Quality Manager are ultimately geared towards business and risk management The Quality Manager often has a keen understanding of the flow of the organization’s business processes Quality Manager Stand Up! © The ISO 9001 Group. 2011 (0). Page 5 Drivers of Big Quality © The ISO 9001 Group. 2011 (0). Page 6 BP Incident – 11 Lives Lost © The ISO 9001 Group. 2011 (0). Page 7 BP Incident – 4.9 Billion Barrels Spilled © The ISO 9001 Group. 2011 (0). Page 8 Deepwater Horizon Study Group Final Report published 3/1/2011 Disaster was preventable had existing progressive guidelines and practices been followed Resulted from multiple violations of the laws of public resource development and proper regulatory oversight (U.S. Mineral Management Service) Failure to contain, control, mitigate and plan rooted in a culture of organizational malfunction and shortsightedness There were multiple opportunities to properly assess the likelihoods and consequences through Risk Assessment and Management Identical blow out occurred 8 months earlier offshore Australia (Montara Commission of Inquiry 2010) © The ISO 9001 Group. 2011 (0). Page 9 Deepwater Horizon Study Group Final Report published 3/1/2011 When given the opportunity to save time and money and make money, tradeoffs were made There were no perceived downsides associated with uncertain things (risk) Result of a cascade of deeply flawed failure and signal analysis, decision making, communication, organization and managerial processes At the time of the Macondo blowout, BP’s corporate culture was one of risk-taking and cost-cutting It is the underlying “unconscious mind” that governs the actions of an organization and its personnel © The ISO 9001 Group. 2011 (0). Page 10 Deepwater Horizon Study Group Final Report published 3/1/2011 Product Failures – Blow Out Preventers failed initially and in following days – Oil spill containment devices failed – Killing the well with heavy mud failed Multiple tests failed to disclose the breach of hydrocarbons that entered the well All of the approved plans and preparations for controlling and mitigating failed or were ineffective Emergency control equipment were destroyed, damaged or were not activated $42.2 Billions spent, damage to the environment, the economy and the oil and gas industry © The ISO 9001 Group. 2011 (0). Page 11 Deepwater Horizon Study Group Final Report published 3/1/2011 Industry Recommendations Made – Upgrade selection of people – Training for normal, emergency and abnormal activities – Employee Competency – Mentoring – Collaboration – Implement Risk Assessment and Management (RAM) – As Low As Reasonably Practicable (ALARP) • Expected level of residual risk involved with a system or operation – Focus on Best Available and Safest Technology (BAST) • Safe and Environmentally conscious operations. © The ISO 9001 Group. 2011 (0). Page 12 Shale Gas Production Proved Shale Gas Reserves 140,000 131,616 120,000 100,000 97,449 80,000 60,644 60,000 40,000 20,000 34,428 23,304 0 2007 2008 2009 2010 2011 Billion Cubic Feet © The ISO 9001 Group. 2011 (0). Page 13 United States Manufacturing Resurgence of Made In America – More companies are bring manufacturing jobs back Increase in natural gas production Increasing demand for a management system driven supply chain Increased use of small to mid-sized organizations to reduce cost – API Spec Q1, API Spec Q2 – ISO 9001, ISO 29001 © The ISO 9001 Group. 2011 (0). Page 14 Prepared For Big Quality © The ISO 9001 Group. 2011 (0). Page 15 ISO Global Survey Results © The ISO 9001 Group. 2011 (0). Page 16 ISO 9001 Growth World 1994 - 2012 © The ISO 9001 Group. 2011 (0). Page 17 ISO 9001 Certifications 2009 - 2012 400,000 350,000 328,213 300,000 250,000 334,032 297,037 257,076 USA 200,000 China 150,000 100,000 50,000 28,935 25,101 25,811 26,177 0 2009 © The ISO 9001 Group. 2011 (0). 2010 2011 2012 Page 18 Gross Domestic Product 2012 $18 $16 16 Trillion $14 $12 $10 8.11 $8 $6 $4 $2 $0 USA © The ISO 9001 Group. 2011 (0). China Page 19 Gross Domestic Product Growth - 2012 GDP 9 7.7 Percentage 8 7 6 5 4 3 2.8 2 1 0 USA © The ISO 9001 Group. 2011 (0). China Page 20 Changes In Big Quality © The ISO 9001 Group. 2011 (0). Page 21 Management System Standards API Spec Q1 Ninth Edition has over 80 new clauses and 5 new sections API Spec Q2 was introduced for Oil & Gas service organizations ISO 9001 undergoing a major revision to be released in 2015 © The ISO 9001 Group. 2011 (0). Page 22 Management System Standards API and ISO – Integration of QMS into all core business processes – Personnel Training & Competency – Risk Assessment & Management – Contingency Planning – Control of External (Outsourced) Processes • Inclusion into internal audit planning – Restrictions on exclusion to requirements – Top Management Leadership and Commitment – Management of Change – Operational Planning & Controls – Control of Production and Services © The ISO 9001 Group. 2011 (0). Page 23 Certification Bodies Certification bodies such as API and ISO certification bodies have become more stringent Passing certification audits are becoming more difficult due to increased scope of management system standards Rates are increasing due to increased program administration and enforcement API has increased their rates by 25% - 200% The same can be expected by ISO certification bodies © The ISO 9001 Group. 2011 (0). Page 24 Business Processes Big Q will mean the integration of your QMS into all core business processes Processes that were traditionally not audited, will now be included in the audit scope – Budgeting • Allocation of funds for required resources – Project planning – Risk management – Health, Safety and Environment – Recruitment and Hiring – Employee Orientations – Oversight Activities © The ISO 9001 Group. 2011 (0). Page 25 Personnel Training & Competency Big Q will mean a properly trained and competent workforce Establishing experience, skill and educational requirements for each position prior to hiring Hiring personnel based upon established requirements Establishing comprehensive training requirements for each position Establishing new employee orientation programs focused on specific job tasks – Not just payroll and insurance Performing competency monitoring and testing © The ISO 9001 Group. 2011 (0). Page 26 Risk Management & Contingency Planning Big Q will mean proactive risk assessment of activities Identifying the probability of the risk becoming realized Determining the impact to internal \ external parties if it does become realized Establishing controls into business processes to manage risk – As Low As Reasonably Practicable (ALARP) Monitoring and testing controls to determine if they will be effective in case the risk does occur Establishing contingency plans and emergency response plans (back-up plans) to the established controls – Based upon worst case scenario – Five What If’s © The ISO 9001 Group. 2011 (0). Page 27 Control of External (Outsourced) Processes Big Q will mean thinking of outsources processes as internal processes Outsourcing does not relieve the responsibility of its organization or liability Increased scrutiny and oversight will be required of suppliers of outsourced processes beyond – Past relationships – Cost – Delivery times Outsourced processes will be included in internal audit planning © The ISO 9001 Group. 2011 (0). Page 28 Restrictions On Exclusions Big Q will mean organizations will be able to claim less exclusions to management system requirements Exclusions must not affect ability or responsibility to meet customer and applicable regulatory requirements – Outsourcing a process will not qualify as an exclusion – Design and Development © The ISO 9001 Group. 2011 (0). Page 29 Top Management Leadership Big Q will mean not only Top Management commitment, but Leadership Top Management will be expected to demonstrate not only through memorandums and newsletters, but through: – Establishment of a culture of compliance – Leading by example – Placing more value on doing things right the first time vs. doing things quickly – Maintaining profitability through reduction of waste vs. taking short cuts that create waste – More focus on long-term results vs. short-term gains – Establishing a preventive action culture vs. corrective action culture – Capturing lessons learned and incorporating back into business processes as necessary © The ISO 9001 Group. 2011 (0). Page 30 Management of Change Big Q will mean organizations must manage first recognize change and then manage it – People – Processes, Procedures – Risk – Training – Technology – Work Environment – Supply Chain – Scope of Work – Laws and Regulations © The ISO 9001 Group. 2011 (0). Page 31 Operational Planning & Controls Big Q will mean more operational planning and controls More planning must be done around the actual operations – Required resources (people, equipment, work activities) – Project \ Quality plans – The Quality Manager involved in operational planning More onsite oversight by The Quality Department to ensure employees and suppliers are complying with system requirements More preventive actions Sharing of potential risks throughout similar operations within the organization © The ISO 9001 Group. 2011 (0). Page 32 Compliant Versus Certified Management Systems Larger organizations are using small to mid sized organizations as part of their supply chain more than ever They want to reduce their cost, but not increase their risk Increasingly accepting of “compliant” management systems vs. “certified” management systems Removes the barriers for small to mid-sized organizations to compete without the cost for certification Levels the playing field © The ISO 9001 Group. 2011 (0). Page 33 Big Quality Data Big Q means Big Data Need to have the ability to capture more data, analyze it and disseminate it quickly Wikispaces – www.wikispaces.com – Similar functionality of ERPs like Microsoft SharePoint that cost $30k or more – Cost between $0 - $83 per month for 100 users – Update documents anytime, from anywhere – Version control – Organize work groups – Video, Calendars, Visitor Counters to make more engaging – Secured permission based © The ISO 9001 Group. 2011 (0). Page 34 Engaging The Workforce © The ISO 9001 Group. 2011 (0). Page 35 The Millennial Workforce Need to be prepared to engage with the millennial workforce (1980 – early 2000’s) Characteristic Focus Confident Not afraid to do what they think is right. If they are trained properly, will be less prone to buckle under pressure to shortcut Self Focused May not necessarily be concerned with overall good of organization. More oversight will be required. Low Attention Span Volumes of procedures won’t work. Less documented procedures. Engaging content such as video and audio. Jump from Job-to-Job May increase the amount of change that needs to be managed. Capturing processes and procedures will help stabilize. Want Flexibility Want information on demand when they need it or want it. Provide it to them via intranet, secured websites, etc. Short Term Focus Focused short term (money, fame & image). Can be countered through increased monitoring, engagement regarding long-term focus. Open Minded Open to new processes, procedures, etc. Be prepared to explain the reasoning behind them. © The ISO 9001 Group. 2011 (0). Page 36 More Engagement Social networking is not going away – Face book (Say what’s on your mind) – Twitter (140 characters) Quality Managers will need to consider how they can use internal social networks to engage their workforce People want more information, but in a manner that takes less effort on their part – Less words – More Video – More Audio Information on demand © The ISO 9001 Group. 2011 (0). Page 37 Big Quality Equals Better Business Big Q means doing things right the first time Quality Managers with a business & risk focus Better Business Equals – Top Management leadership – Management of Change – Integration of QMS into all core business processes – Risk assessment and management – Contingency planning and testing – Training and competent personnel – Operational planning and controls – Control of external (outsourced processes) – Restrictions on exclusions to management system requirements © The ISO 9001 Group. 2011 (0). Page 38 Question & Answer Please feel free to ask any questions at this time. © The ISO 9001 Group. 2011 (0). Page 39