Broad SAP Implementation Project

advertisement

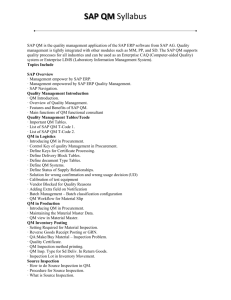

Broad SAP Project Approach & Functionality Implemented 06/23/06 Agenda • Project Goals • Project Scope and Approach • Timeline • Functionality – Master Data Management – Planning – Procurement – Inventory Management – Cost Tracking – Production – Quality Management Project Goals • Enable the Broad to be the lowest cost provider of genomic sequencing data. – Improve Production cost tracking – Implement product costing (cost per read) – Simplify Purchasing and Financials, including the addition of ECAT purchasing – Simplify batch creation and inventory management processes – Improve “ease of use” for highly repetitive transactions • Enhance operational performance – Improve shop floor tracking of batch numbers to enable timely troubleshooting – Improve quality management by tying inspections results to materials and batches produced • Fully integrate with the MIT SAP system, to reduce long term IT costs – Eliminate a grant funded legacy system (OPM), & multiple system interfaces – Eliminate the dual User licenses and system maintenance contracts – Provide a scalable platform, that supports the addition of new/more complex business processes Project Scope • Replace Oracle OPM with SAP functionality in the following areas – Master Data Management – Planning – Procurement – Inventory Management – Cost Tracking – Production – Quality Management • • Provide specific functional enhancements to improve ease of use & increase efficiency – Including direct use of MIT SAP Purchasing & Financials Out of scope items – clearly defined and agreed upon Project Approach • Team expectations clearly defined • Team members educated on basic project truths – Scope, Schedule, Budget (resources) • Measurable acceptance criteria for project success • Collaborative effort between Broad and IS&T – Co-team leaders – established a cohesive team – Broad business and IS&T members “paired” – Active sponsorship and steering committee • Business Power Users dedicated to the project – You are empowered. Make the decisions! – Deal with tough or controversial issues up front – don’t wait! – Involve everyone, at every step • Extensive planning and scoping analysis conducted prior to project kick-off (2 month effort) • Project scope under change control at the onset Project Timeline Nov • Project Prep • Plan • Resources • Infrastructure • Blueprint • Flows • Policy & Process • Spec’s • Walkthrough • Realization • Config (DEV & TST) • Playbacks • FRICE • Integrated Test 1 • UAT (IT2 & Regression) • Final Prep • Build (PS1) • User Training • Convert • Go Live & Support • Week 1 Support Dec Jan Feb Mar Apr May Jun SAP Functionality Implemented Overview Broad Flow Print/Display Reports Set up Master Data • Materials • BOM/Recipe • Costs • Info Record Input a Forecast Run MRP Print/Display Reports Release Req’s Create PO’s Print/Display Reports Pay Invoices Print/Display Reports Receive PO’s Inventory Movements Goods Issue Project Expensed Material Create a Process Order Mini-Mart Expensed Material Create & use an Inspection Lot Pass data to/from SQUID Misc Goods Receipt Backflush (fixing as necessary) Purchase Expensed Material Set up Quality Master Data • Groups • MIC’s • Insp. Plans • SPC param Print/Display Reports & SPC Print Checks SAP SAP Modules at Broad • SAP Modules include – Materials Management (MM) • • • • Master data (material, vendor, purchasing information record), Purchasing Material Requirements Planning (MRP) Inventory management (goods issue, goods receipts, goods transfer, physical inventory) • Batch management – Quality Management (QM) • Inspection plans / Master Inspection Characteristics, Inspection lots, Inspection Results Recording and Statistical Process Control – Quality inspection stock – Production Planning (PP) • Process orders and master recipes including Bill of Materials – Financial and Controlling (FI/CO) • Product Costing – Cross-Application Components • Document Management • Workflow Broad is an SAP Plant • SAP defines a plant as a location that holds stock (inventory), contains service or maintenance facilities and or manufactures products • Each plant within SAP can have many unique features – Factory calendar – identifies working days – Storage locations – location where stock is physically kept in a plant – Master data - materials, work centers, bills or material, recipes, batch – Planning requirements – reorder point, forecast based – Quality mgt – inspection plans/master inspection characteristics Master Data Management • Plant Calendar specific for broad • Organizational Structure (Plant, Purchasing group, etc.) • Material Master (Part Numbers) – Re-Order Points – Lead time – Standard cost • • • • • • • • Bills Of Material (BOM’s) Master Inspection Characteristics (MIC’s) Inspection Plans Recipes Reason Codes Purchasing Info Records Purchasing Source Lists Release/Approval Levels (Req. & PO) Planning • Forecasting • Long Term Planning (LTP) • Materials Requirement Planning (MRP) – Finished and Semi-finished (Make) – Raw materials/Components (Buy) – Bulk materials (Buy) • Cash Flow Analysis • Actuals vs Budget Comparisons Procurement • MRP generated Purchase Requisitions • Directly created Purchase Requisitions – In SAP – Via SAP Web • Purchase Requisition approval workflow • Purchase Order creation using Req info & master data • Electronic document management for both Requisitions and PO’s (RFQ, Quotes, Spec’s, etc) • Purchase Order approval workflow • Automatic Purchase Order print/fax • Single screen for Expensed material Receiving • Custom “Confirmation” transaction for Inventory • Quality Hold on Invoice payment until after approval (where desired) • Automated 3 way match for Invoice payment Inventory Management • Goods receipts – – – – Purchase Orders/Production Orders Cost Centers Projects/Internal Orders Mini-Marts/Groups (WBS cost objects) • Goods Issues – – – – • • • • Production Orders (including Backflush) Cost Centers Projects/Internal Orders Mini-Marts/Groups (WBS cost objects) Goods movements within Stockroom Cycle Counting & Physical Inventory Restricted and Un-restricted stock Connected/Synchronized Unit and $$$ Production • Process orders – Capturing costs – Goods Issue and/or Back Flush • Automated batch assignment • Debugging via Lot Genealogy (from Supplier to finished product) • Yield tracking • Integration to Quality results tracking • MRP Planning capability Quality Management • Automated Batch # assignment • Lot Genealogy from Supplier to End Product – Feeds to Broad Data Warehouse (SQUID) reporting • Invoice payment hold until Quality approval on Receipts (where desired) • Pre-defined Master Inspection Characteristics’ and Inspection Plans – Consistency – Ease of maintenance • On Line Usage Decisions – Inventory Units and $$$ moves to correct bucket automatically • Results tracking and Alerts • Statistical Process Control (SPC) charts Cost Tracking • Monthly Updated Standard Cost tied to each material • Material $$$ tracked to individual WBS cost objects, internal orders (projects). – Based on Standard cost X Unit Qty – For PO’s, Goods Issues, Returns, etc – Single transaction moves $$$ and Units • Variance accounts to isolate particular activities – Reason codes to provide granularity • Expanded reporting (Inventory $$$, PPV, etc) • Ability to track actual cost expended against a preestablished budget • Capability to plan and track Labor costs as well, though this is not being used by the Broad