Power Uprate Lessons Learned Component Specific Lessons

advertisement

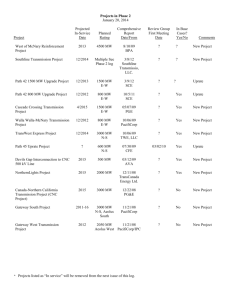

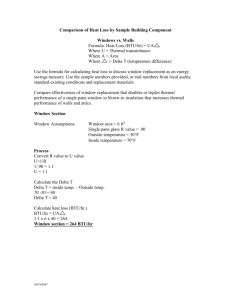

Power Uprate Lessons Learned Point Beach Nuclear Plant 2011 Units 1 & 2 Kelly Oetting BOP System Engineer FSRUG 2012 Conference January 23-26, 2012 Power Uprate Lessons Learned Power Uprate Scope • • • • • • 2 Westinghouse 2 – Loop PWR, Unit 1 1970, Unit 2 1972 545 MWe to 637 MWe 1540 MWth to 1800 MWth 17% Approximately 35 Major Modifications for Each Unit Dozens of Smaller Supporting Modifications Power Uprate Lessons Learned Unit 2 Diagram 3 Power Uprate Lessons Learned Unit 1 Diagram 4 Power Uprate Lessons Learned Duration • Unit 2 – 120 Days (3/1/11 - 6/19/11) • Unit 2 – Power Ascension Testing 12 Days (6/19/11 – 7/1/11) • Unit 1 – 75 Days (10/3/11 – 12/17/11) • Unit 1 – Power Ascension Testing 12 Days ( 12/17/11 - 12/29/11) • The Difference…..Mostly Lessons Learned! 5 Power Uprate Lessons Learned Lessons Learned Major Categories • • • • • • • 6 Preparation Resources Foreign Material Exclusion (FME) Control / Chemistry Control Testing Configuration Control Technical Conscience Component Specific Lessons Learned Power Uprate Lessons Learned Preparation • • • • • • • Design Packages – Are They ready? Design Final? Work Packages Planned? Parts On-Site/Available? Spare Parts On-Site/Available? Testing Packages Complete/Ready? Test Equipment Identified/On-site/Available? Pre-Outage Work Complete? (scaffolding, insulation, rigging, etc..) • Is Your License Amendment Approved? 7 Power Uprate Lessons Learned Resources • Contractors – Majority of Work – Remember…They Eventually Leave • Early DEDICATED in-house resources for design reviews and approvals • Need dedicated in-house resources from Engineering, Operations, Maintenance, Procedure Writers, Document Control, Drafting • Procedure reviews – Who’s doing it? Need knowledgeable people – HUGE resource drain (50% of system engineer’s time during outages) • Don’t forget in-house participation in testing, especially I&C • Who will do the equipment database and vendor manual updates? • Resources Spare Parts Management, out with the old – in with the new • Resources PM updates • Routine System Engineering Duties May Have To Wait 8 Power Uprate Lessons Learned Foreign Material Exclusion (FME) Control / Chemistry Control • • • • • • • • • • • • • 9 Na, F and Fe values above CEI limit for 25 days (U2) 10 days (U1) GMAW weld rod, sodium silicate binding agent Management Buy-In for Clean-Up Plans Specific Acceptance Criteria (quantitative not qualitative) Better physical barriers (covers, tape) Watch out for weld blanket (fraying and dye) Remove anti-rust coatings prior to installation TIG for root pass Smoke exhaust ventilation Flushing (high pressure wash & high volume wash) Grinding wheels – fibers plugged start-up strainers Start-up strainer design (mesh size? Back flush capability?) Consider a start-up polisher (trailer) Power Uprate Lessons Learned Testing • Get Involved Early • Get the Right People Involved (In-House and Outside Expertise) • Predicted Values May Not Match Actual – Have A Plan To Evaluate • How Will As–Left Setting Be Documented? • SQA Program? • Software Setup and Tuning Parameters Specified in Design? • Factory Acceptance Testing Specified in Design? • Bench Cal and Test Prior to Installation – huge time savings between U2 to U1 • Equipment Tagging Complete PRIOR to Testing • Finish ALL of the Start-Up Testing • Don’t remove test instrumentation early • FWH level optimization (knee test) 10 Power Uprate Lessons Learned Configuration Control • NAMS/PASSPORT Software not the most user friendly • CRNs – Changes to original design package – cross reference not enough • Revise original design package to show final configuration if possible • Detailed titles and descriptions for CRNs • Make sure CRNs for 1st Unit incorporated on the 2nd Unit 11 Power Uprate Lessons Learned Technical Conscience • • • • • • 12 Summit Fever! Accountants vs. Engineers Schedule Impact vs. Long Term Reliability Flushing (strainers, duration, chemistry requirements) Accepting Poor Workmanship (condenser wall) Spend a Little More for Increased Reliability (ES Exp Jnts) Power Uprate Lessons Learned Component Specific Lessons Learned • Ensure Vendors Actually Meet The Agreed Upon Specifications • Pumps; 30+ runs at manufacturer before pump acceptable (vibs, curve shape, alignment) • Pump thermal growth nowhere close to calculated, measure it. (Essinger Bars, Rotalign, etc..) • Pump nozzle loads required significant piping rework (vendor couldn’t accept piping designer’s higher values) • Pump oil leaks due to thrust disc drive nut – wrench flats machined in wrong location • Supplied Pump/Motor coupling keys too large, didn’t match half keys used for component balancing • New Motors: Rotors made in China, failed on the test stand, rework; 5 new rotors had to be manufactured, shop in China never made 3600 rpm motors before 13 Power Uprate Lessons Learned Component Specific Lessons Learned (cont.) • • • • • • • • • • 14 Rewound motors: lower starting amps and torque, longer acceleration time caused rework for calculations and over current relay settings Valves – trim not sized correctly, valves full open at 100% pwr Skid mounted piping welds not per code or lacked vendor provided evaluation and poor quality Skid mounted components not rated for ambient conditions Skid mounted dp instruments piped backwards Small bore piping cracked socket weld, use 2:1 weld leg configuration Painters will paint everything, even moving parts Vendor manuals and drawings not updated timely Controller power supply failures caused mid outage design change for feed reg valve Swapping from backup to primary feed reg valve controller, need to wait 15 seconds and follow specific sequence or valve will go full shut – software glitch Power Uprate Lessons Learned Component Design Change Details Before EPU After EPU Bryon Jackson - DVS Sulzer – CD/BBS 1 1 6000 rpm 3600 rpm Yes – 3.367:1 No – Direct Drive Design Flow 7800 gpm 9300 gpm Design Head 2180 ft 2200 ft Mini Recirc 500 gpm 4000 gpm Westinghouse TECO Horsepower 5000 6200 Rated Speed 1789 rpm 3582 rpm Feed Pump # Stages Rated Speed Speed Increaser Feed Pump Motor 15 Power Uprate Lessons Learned Component Design Change Details (cont.) Before EPU After EPU Byron Jackson – 24 KXH Flowserve – 28 APKD 7 7 Rated Speed 1180 rpm 1188 rpm Design Flow 4720 gpm 5700 gpm Design Head 800 ft 760 ft Westinghouse TECO Horsepower 1250 1500 Rated Speed 1190 rpm 1189 rpm Condensate Pump # Stages Condensate Pump Motor 16 Power Uprate Lessons Learned Component Design Change Details (cont.) Before EPU After EPU Westinghouse (shell) Southwest Eng. (tube bundle) Yuba 41 ft 9 in 49 ft 68 in 79.25 in Heat Transfer #1 147,500,000 Btu/hr 141,100,000 Btu/hr Heat Transfer #2 116,700,000 Btu/hr 126,600,000 Btu/hr Westinghouse (shell) Southwest Eng. (tube bundle & channel head) Yuba Length 42 ft 8 in 42 ft 8 in Diameter 42.75 in 49 in 153,500,000 Btu/hr 184,300,000 Btu/hr #1 & #2 LP FWHs Length Diameter #3 LP FWHs Heat Transfer 17 Power Uprate Lessons Learned Component Design Change Details (cont.) Before EPU After EPU Struthers Wells Yuba Length 34 ft 38 ft 4 in Diameter 46 in 52 in Heat Transfer 174,000,000 Btu/hr 229,498,000 Btu/hr #5 HP FWHs Yuba Yuba 53 ft 2 in 48 ft 51 in 59 in 334,776,179 Btu/hr 411,333,000 Btu/hr #4 LP FWHs Length Diameter Heat Transfer 18 Power Uprate Lessons Learned Component Design Change Details (cont.) Before EPU After EPU Copes Vulcan Copes Vulcan / SPX Controller Masoneilan - pneumatic Yokogawa US1000-11 Positioner Moore 72 - pneumatic Fisher DVC 6010 Transmitter Float – part of controller Rosemount Guided Wave Radar 5300 Series FWH Level Control Valves 19 Power Uprate Lessons Learned Component Design Change Details (cont.) Before EPU After EPU Copes Vulcan Copes Vulcan / SPX Controller Foxboro - pneumatic Yokogawa UT55A Positioner Moore 72 - pneumatic Fisher DVC 6010 Transmitter Foxboro - pneumatic Rosemount Guided Wave Radar 5300 Series Feedwater Regulating Valves Copes Vulcan Copes Vulcan / SPX Actuator Copes Vulcan RA Hiller Controller Foxboro 62 HB - pneumatic Yokogawa YS-1700 Positioner Bailey Model AP-4 - pneumatic Fisher DVC 6005 base unit DVC 6025 feedback unit Did Not Exist Flowserve Gate Valve Heater Drain Tank Level Control Valves Feedwater Isolation Valves ( new) Actuator 20 Hiller - piston double acting